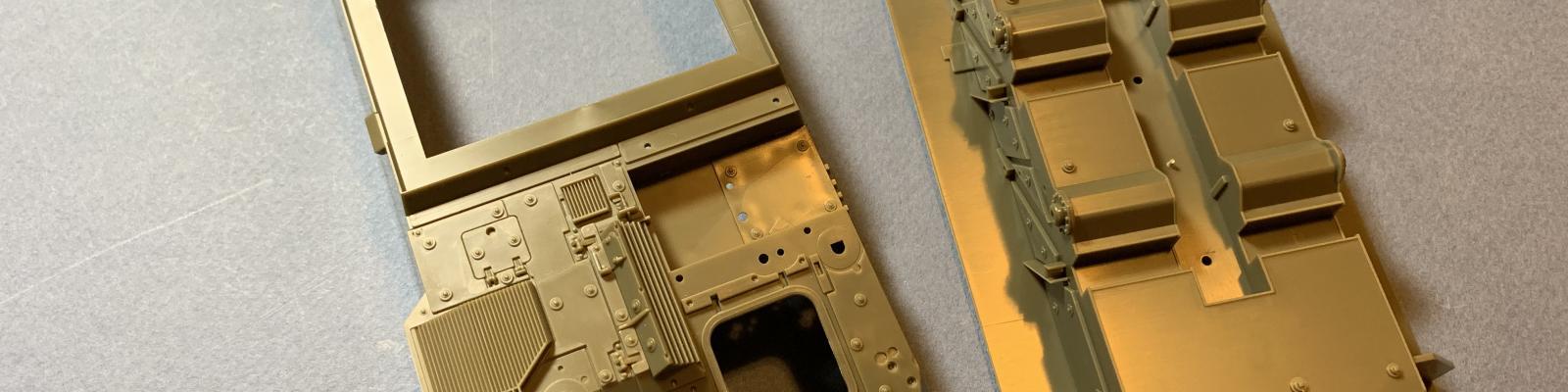

The Einheits-PKW (German for 'standard passenger cars') were supplied to the Wehrmacht between 1936 and 1943 in the three versions Leichter Einheits-PKW, Mittlerer Einheits-PKW and Schwerer Einheits-PKW (light, medium and heavy passenger car). These vehicles were supposed to replace the civilian vehicles previously procured by the Reichswehr with cross-country mobile vehicles that conformed with military requirements while simplifying logistics and maintenance by using standardized components. The program achieved neither of these goals. (Source: https://www.wikipedia.org) However, if your goal is to build a very highly detailed model in 1/35 of this vehicle (the Kfz 12 version included a tow bar), then this Bronco kit definitely delivers.

Welcome to IPMS/USA Reviews

Introduction: The primary organization of the IPMS/USA Review website is by IPMS/USA National Contest Class. Within each Class there are sub-menus by kits, decals, books, etc. The Miscellaneous Class is for items that are not class specific or that cross two or more classes.

IPMS/USA Members: We encourage you to submit reviews, both here and to the Journal. To volunteer for membership in the IPMS/USA "Reviewers Corps" and submit your own reviews, please read the Guidelines For Submitting Product Reviews.

Manufacturers, publishers, and other industry members: IPMS/USA is pleased to offer your company the opportunity for product reviews. All product reviews are performed by IPMS/USA members, and are posted in the publicly-accessible section of our website. With very few exceptions, we perform full build reviews of new kit releases, aftermarket products, and supplies. If you would care to provide product samples for review, please contact John Noack, IPMS/USA 1st VP.

To learn more about IPMS/USA, please see our About Us page.

The Dan Fink Metalworks Speedwagon is a wonderful car and Revell has made a terrific kit.

Engine

The small block Ford engine goes together very well but has no alternate parts. I guess because the kit represents an actual car. Parts fit and looks good when completed.

Interior

Interior has separate side panels that can be easily detailed due to the excellent engraving.

Body

The body panels fit like they’re supposed to fit without issues. The fenders, tub and hood are separate pieces. Fenders, hood and grille are probably from the Revell ’32 Ford 5 window coupe kit. I chose to use HOK majik blue pearl while the wood panels were hand painted in a 4 step process.

Chassis

I think the chassis/frame parts were used from another kit – possibly the ’32 Ford 5 window coupe. Nothing wrong with that because it builds just wonderfully.

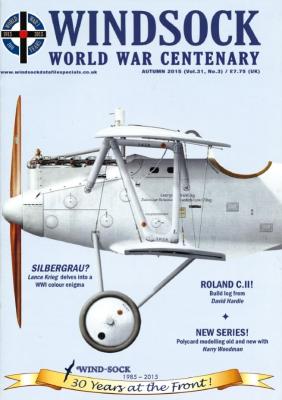

The Autumn 2015 edition of Windsock World War Centenary is the third edition of Volume 31. This edition’s cover story features an enlarged version of Ronny Barr’s Pfalz D.III 4059/17 side profile as Lance Krieg dives into the Silbergrau color debate. David Hardie provides his build notes for the Wingnut Wings Roland C.II ‘Walfisch’ along with 19 photos illustrating how he did it.

The first of a series by the late Harry Woodman focuses on an unpublished update to his rare Scale Model Aircraft in Plastic Card that portends to be a must have. This feature provides updates to the original and is supplemented with plenty of archival material and color photos. The color feature by arvoart.com is the 15th part of the Great War Paint and depicts fifteen aircraft, highlighted by the Swedish Thulin D. Of course all the usual suspects also are here with reviews of on-topic books, journals, calendars, kits, accessories, and last, but not least, figures

Chapters include:

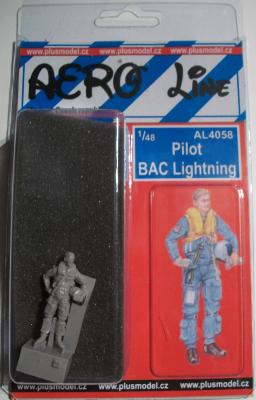

One of my favorite aircraft is the BAC (English Electric) Lightning and having a few in my stash I jumped at the opportunity to have this pilot figure.

This resin figure is very well detailed and molded with very little flash as is the norm with PlusModels products.

I do not normally get figures as I am not very good at painting faces so avoid it at all cost normally. But this figure was so good so I decided to do a full paint job as best as I could. When finished, I was pleasantly surprised how it turned although the quality of the figure was the reason it looks good not my painting skills when it comes to figures.

This is an excellent figure and I will get more by PlusModel.

Thanks go to Plus Models for providing this kit to review and IPMS USA for allowing me to review it for them.

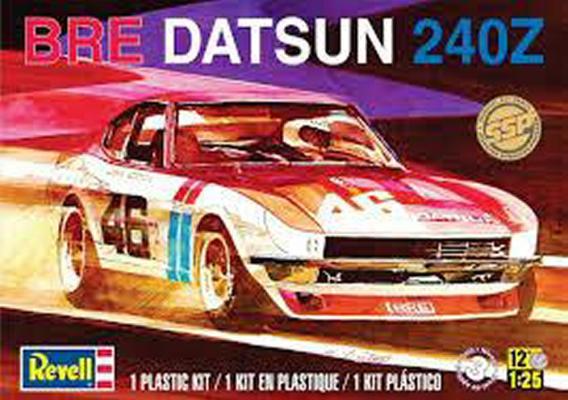

After dabbling in automotive design at GM, Pete Brock started his own design firm in 1965 known as Brock Racing Enterprises, (BRE). His designs were successfully used in GT, CP and Trans Am class racers in the sixties and early seventies. This kit replicates the C Production class winning 1969 Datsun 240Z driven by John Morton.

The Kit

This review covers the BRE Datsun 240Z 1:25 Scale Revell Model Kit #85-1422. This is a Limited Production SSP Series model and a re-released kit from 1972. Produced as a one-time offering kit and rated a skill level 3 build. I think that‘s about right due to some difficult decals, tutone paint, and some altered build sequences. There are at 105 parts molded in white, clear and chrome parts, along with vinyl tires and engine tubing. This kit features a detailed 6-cylinder racing engine, vinyl oil lines, front and rear spoilers and soft black tires. Finished dimensions are: Length: 6-5/8 ", Width: 2-5/8", Height: 1-15/16".