Tupolev G-5 Mod. XIII Torpedo Boat

Background

The G-5 was a Soviet motor torpedo boat built before and during World War II. Approximately 300 were built, of which 73 were lost during the war. Four were exported to the Spanish Republican Navy during the Spanish Civil War. Three were captured by the Finns during the ‘Winter War’, with two being used operationally against their former owners. Others were transferred to North Korea after the war.

Tupolev’s first twin engined motor boat was the GANT-3 Pervenets (first born) which was completed in March 1927. Utilizing two 600 hp aviation engines, the duraluminum speed boat achieved a maximum speed of 50 knots. The GANT-3 led to a production version later in 1927 called the ANT-4. Fifty-nine were manufactured between 1927 and 1931, officially entering service on April 8, 1931. The Tupolev G-5 (ANT-5) class was an improved and enlarged version of the ANT-4. The G-5 carried two 21” torpedoes instead of one with 329 being built between 1933 and 1943. The G-5 in initial tests in the Black Sea achieved a speed of 63.5 knots (73.1 mph), albeit unarmed.

The G-5 was a single-step, hydroplaning design with a whaleback upper hull. It was mainly built from duralumin which saved a significant amount of weight, but greatly complicated its use in service because of duralumin's susceptibility to galvanic corrosion in salt water. One captured Soviet torpedo boat commander said that G-5s could only be kept in the water for 5–7 days during the summer and 10–15 days during the winter before it had to be removed from the water and treated with anti-corrosion measures. The hull was divided into three compartments by two transverse bulkheads. The cabin was very small to reduce top-heaviness, and crewmembers could not stand up inside it.

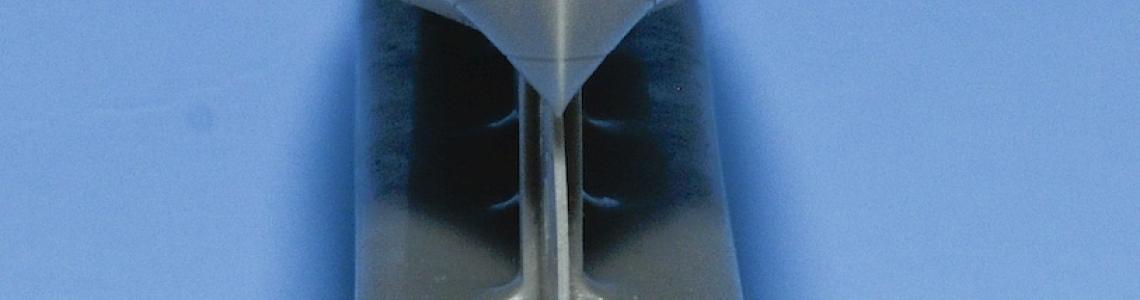

The G-5 was designed to use a version of the Mikulin AM-34 aircraft engine adapted for maritime use as the GAM-34. The two engines were fitted in the forward compartment of the hull. Each engine had its own transmission and drove a bronze propeller 2 ft 2 in in diameter.

The two torpedoes were carried in troughs set into the rear deck in a manner derived from that used by the British WW I-era coastal motor boats captured by the Soviets during Russian Civil War. The torpedoes were deployed out the back of the trough by an arbor with a bell-shaped head that was activated by an explosive charge. The torpedo motor was not activated until a wire trailing from the boat snapped, giving the boat time to turn away from the target. This launching system was very light, but it required additional training to properly aim the torpedo and prior coordination when making massed torpedo attacks to prevent the boats from ramming each other or the torpedoes.

The gun armament initially consisted of a single 7.62 mm machine gun, but this was upgraded to a 12.7 mm DShK machine gun in later models. Some later boats carried two DShKs although the mounts varied; some were placed in a tub in the forecastle, but others carried theirs in a rotating turret behind the superstructure, above the torpedoes. Some boats carried 82 mm (3.2 in) ROFS-82 or 132 mm (5.2 in) ROFS-132 rocket launchers in fixed mounts above and behind the wheelhouse.

The Kit

The Brengun 1/144 Tupolev G-5 XIII Torpedo Boat consists of 31 pieces of gray resin and a photoetch fret with 35 pieces. At first glance the resin looks well done with only a few minor bubbles. I was not able to find a call-out for photoetch #3 in the instructions and it has yet to be installed on the model. There are decals for two boats: TK-307: Cap. Protsenko, Sulin, 1944; and TK-334: 1st BTKA, Yalta, April 1944. The decals provided are cabin codes and both boats are painted the same, Light Gray Green on top and Dark Gray on the bottom.

Construction

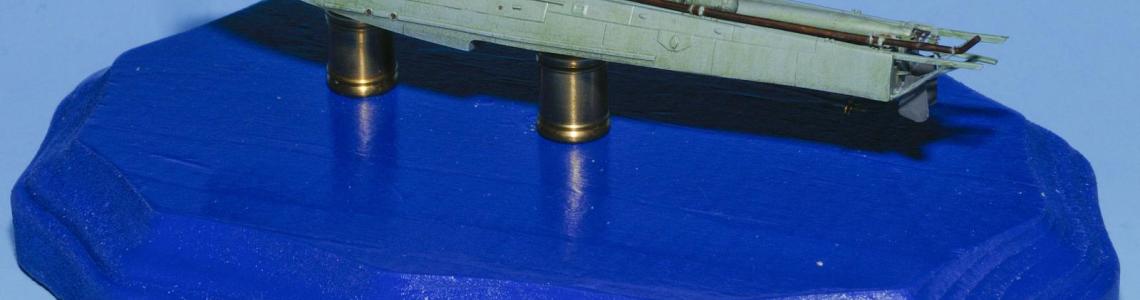

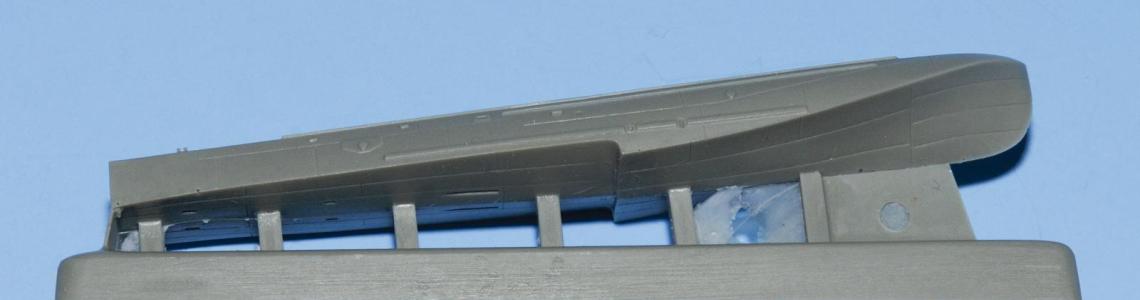

I cut out the hull from the block using a fine tooth razor saw. A few scrapes with a #11 blade and sanding with a 4000 grit pad easily removed all the pour stubs. I addressed the visible resin bubbles with superglue. Next I drilled two mounting holes in the hull that could handle 4-40 x 1.5” brass machine screws and test fitted them to the wooden display base.

Turning my attention to the cabin, I sanded the base of the cabin to fit properly into the hull. It took a bit of time as the initial fit was very tight resulting in the cabin base twisting just a bit. After carefully filing the cabin mount to fit, I began installing the photoetch window frames (pe#1). Using a pair of razor blades I bent each joint about 30-degrees before super gluing the center front window frame to the cabin. Once set, I carefully pulled the next window frame tight to the resin cabin and superglued it. If you are really careful, the photoetch frame fits extremely tight to the cabin windows.

Next up I glued down the forward cabin hatch (pe#18). The fit on this part left a bit of extension overhanding the front window, and I ended up swiping the protruding brass a few times with a small flat file to bring it flush to the resin.

Up next, I addressed the two torpedoes. Again using my photoetch saw, I removed the front and rear resin pour stubs. I left the two interior pour stubs to ease handling. A couple swipes with a small metal file easily smoothed out what remained on the front and rear pour stubs. Grabbing the horizontal tail (pe#6), I carefully superglued them to the tail of the torpedoes. Next up was the vertical tail (pe#5). I used a bit of slow set superglue to the vertical mount and slid it on. I used a small lego block to makes sure everything was square and then hit the tail assembly with superglue accelerator. It is important that you make sure the vertical goes all way up on the horizontal tail so that the rear mating surfaces meet. The vertical tail has quite a bit of flex in it once separated from the fret and could easily get wopperjawed.

Back to the hull and cabin, I slid the cabin into the hull and superglued the front of the cabin base to the hull. After about two minutes and applied superglue to the right rear cabin base and then two minutes later to the left rear cabin base. Mind you, this was after lots of fiddling to make sure that the cabin was going to fit to the hull properly. Once I got it to fit to my satisfaction, I used superglue to fill around the seam.

While the boat was still upright, I attached pe#8 to the foredeck. Because of the upper deck’s whaleback shape, pe#7 does not fit as is. After removing pe#7 from the fret and trimming, I ended up rolling it lengthwise on a wooden dowel to get some curvature to it. After rolling and test fitting, rolling and test fitting, I eventually got to the point where I was happy with the fit and secured it with superglue to the upper deck.

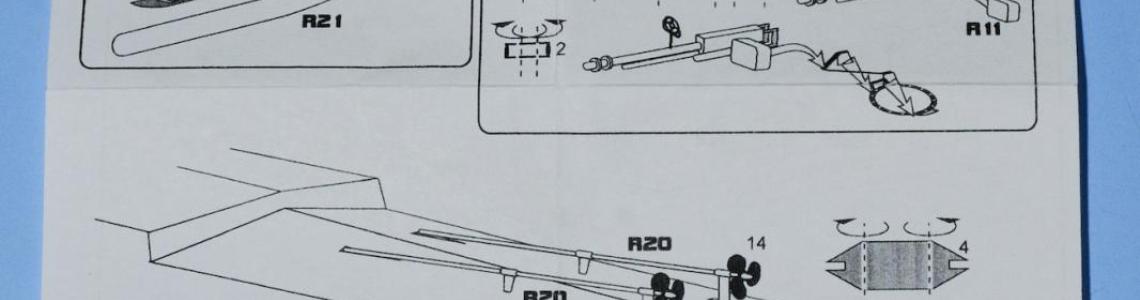

I found a small plastic container around 1” tall and about 2.5” in diameter and was able to flip the boat upside down and yet still clear the cabin. Once I secured the hull with Tamiya tape, I approached the propeller shaft and blades. The propeller shafts were removed from their pour blocks with a razor saw, and then trimmed with a small file. I then discovered the photoetched propellers would not slide on the shafts. I eventually ended up using the razor saw to cut off the end of the shaft, superglued the props to the shaft, and then superglued the tips that I had just cut off. Or at least I tried that. Using tweezers to place the prop tip onto the prop only ended in the tip flying into the air and into infinity. Frustrated, I decided I would do better on the next one and carefully attempted the placement, only to succeed in getting the second prop tip to also fly through the air into a wormhole. I tried to think that no one would notice, but just couldn’t convince myself that the props looked right, so I ended up using the end of a sharp toothpick for both props. Maybe not perfect, since the toothpicks were more pointed that the original resin.

After the previous fiasco, the rudder brackets and rudders were a breeze, but do be careful they are left and right handed. I used two razor blades to bend the rudder brackets to 90-degree angles and mounted them to the rear of the boat with superglue. The rudders easily mounted into the tabs on the rudder brackets using superglue gel followed by a touch of accelerator once I was satisfied they were on correctly. Although it really doesn’t show it in the instructions, the rudders both have braces that need to be bent horizontally to the rudders and superglued to the rear of the boat.

With the bottom of the boat essentially done, I mounted the boat onto the wooden base using the 4-40 brass screws and two brass finials. I added the gun mount rings; flipping up the hand holds to a 45-degree angle with my trusty razor blade. I superglued the resin bow flag mast (R9, pe#17) and the vents (R8) to the deck. The rear supports, R13 and R14 were superglued on along with their resin braces (R3 and R12). Next up was the resin compressor and tank (R18, R19, pe#10).

The most difficult part for me on this model was up next: Adding the toe rails (pe#23) to the forward deck (pe#7). Although there are location holes in the forward deck (pe#7), I had great difficulty securing the toe rails. I’m sure this was mainly my own ineptitude, but I literally spend days supergluing the toe rails to the deck, then pulling them back off as I was not satisfied how they sat. I’m still not happy with them, but I eventually moved on. The other two sets of toe rails (pe#16, pe#19) were a lot less drama. The cabin handrails (pe#23) up next gave me the willys, but with a bit of pre-bending went on with ease. Once the cabin handrails were set, I superglued the searchlight (A7) and the air-horn (A6) to the cabin. The cabin side hand rails (pe#12) were superglued next. The port handrail went on fine. The starboard hand rail disappeared into the night. I also superglued the antenna mast (A16) at this time, but I came to regret it. I would strongly suggest not placing the antenna mast on until you are ready for final painting as I managed to break it off twice in different places.

The exhaust assembly (R4, R5, R15) required a bit of care in fitting and alignment. I had to trim R15 a hair to get a good fit, but overall looked good done.

I saved the machine guns for last. I used my razor saw to remove the guns (R10) and their magazines (R11) from the casting block. The magazines have a nice little tab that inserts into the guns. I folded up the gun handles (pe#2) and brought out my smallest tweezers to attach them to the gun butt. I had great difficulty in orientating the gun handles to fit the rear of the gun and ended up snapping the barrel of one of the machine guns off. The second machine gun got the handles to fit, but during painting, the handles separated a bit and now are at a slight angle. The gun mount (pe#17) folded up well and I mounted it to the gun mount ring (#16). I then placed the machine gun on the assembled mount (pe#17) and secured the gun sight (pe#11).

Painting

I painted the entire kit with Vallejo acrylics. I primed the entire model with Light Ghost Grey. After several days of drying, I painted the bottom hull with Dark Sea Grey. I used Model Color Light Green as a wash to get to a Soviet green-grey coloration for the boat’s topside. I used a Model Color Light Brown as a wash on the bottom hull. I painted the exhaust Rust and the machine gun Panzer Dark Grey. The Cabin interior was painted Mud Brown and washed with Panzer Grey. The cabin windows were painted Panzer Dark Grey and once dry, I dabbed on some future to obtain a glassy look.

Decals

I used the decals for Cap. Protsenko, Sulin, 1944. I applied Future as a base to eliminate any chance for silvering. The decals came off the sheet cleanly, went on the cabin side with no problems. Once dry I dabbed on Vallejo Clear Matte to seal the decal.

Overall Evaluation

Highly Recommended. This is a smaller kit (inside of 5” in length) than I’m used to, but it’s really well done. Most of my difficulties were of my own making, especially with the toe rails and the machine gun assembly. That being said, I’m planning on buying this kit out of my own pocket to do it again, hopefully with less drama. By no means should a resin and photoetch beginner cut their teeth on this kit, but it would be fine for those with more experience under the belt. I would recommend that one be sure to have the appropriate tools on hand. I for one will be investing in some yet smaller tweezers.

My thanks to Hauler-Brengun and IPMS/USA for the chance to review this great kit.

Highly recommended!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews