Kittyhawk UH-1N

First, thanks to Glenn for providing IPMS USA with this kit, and IPMS leadership for passing it on to me.

Kitty Hawk’s new UH-1N has obvious ties with the recently released UH-1W from the same firm. The “Whiskey” has four-bladed main and tail rotors along with scabbed on antenna and systems, giving it a purposeful, definitely non-aerodynamic look, along with weaponry fit for a short, hot firefight. The kit also draws on the recently released UH-1D/H from Kittyhawk, as many of the sprue trees are from that kit as well. The UH-1N (November) however, was originally developed under Bell’s auspices of the natural improvement of a helicopter in overwater and hot, low-density air environments, whereby two-engines are better than one. The “November” has proven longevity and is still in operation almost 47 years since inception. It is the legacy of the original “Huey” line from the 1960’s… and morphed into the Whiskey and other commercial variants.

In my opinion the release of the UH-1N was only a matter of time, relying on the modular construction of the recently released UH-1H tail boom and forward cabin/cockpit of that earlier aircraft having the same basic structure and layout. In this, the UH-1N kit retains the original seating arrangements, tail rotor boom and structure, and the original two-bladed rotorhead with transmission. This kit’s rotor does not exhibit the extended-chord UH-1N main rotor blade. I don’t have sufficient knowledge of the details to know which Novembers had this rotor blade arrangement, other than USAF birds did.

Much of the kit devotes extra details to the weaponized and sensor-laden versions of the November. In my case I wanted a slick, and the final result came in close. As this is a review of the kit, I opted for the harder paint scheme of the white and orange, verses just the gunship Gray “E”… plus I liked the final look.

In this UH-1N kit, there are refinements which provide clues as to the “H” model heritage and thought process at Kittyhawk. This is reflected in what may be considered “errors” in the instruction sheet, which are frequently nothing more than copies of the UH-1W instructions including drawings and parts for the latter interspersed with the UH-1N. Although this appears at face value to be an economy issue, the relative newcomer would not be impressed with trying to figure out what goes where. The instructions need to totally match the kit in the box. This needs to be addressed to improve the product, and ultimately sales. Some people find this a non-starter.

Foot Stomper please, Kittyhawk… Simply put, many will complain about KH instructions once again. I’m not, but must as a reviewer point out the fact the basic assemblers out there will have complaints. So, Kittyhawk, be ready for more complaints from the masses. I’ll be happy to help in the future if you desire to clean this up a bit. Your company has come so far and I look forward to each release. You of all companies have listened to what the polls say we will purchase… now’s the time to up the game for what’s in the box besides the parts.

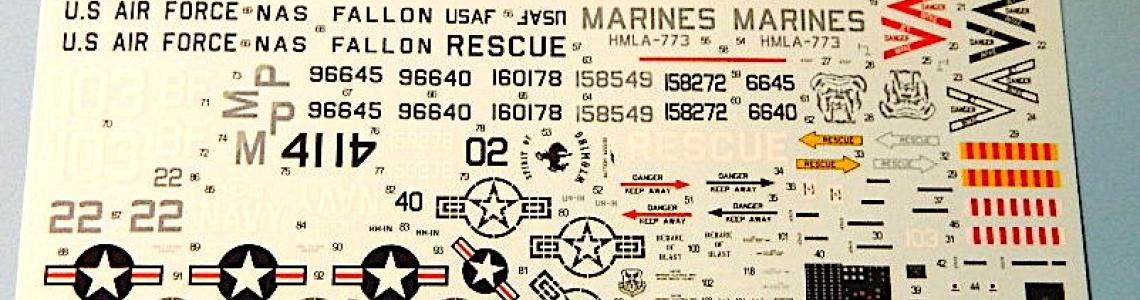

My initial recommendation on opening the kit is to open the paint schemes flyer and figure out what you intend to replicate so you can figure out which of all the various versions you will be modifying the basic kit to portray: A VIPSAM USAF Gray “N” with white top, and a rather attractive white overall with Naval Red/Orange rescue scheme markings are first up. Other marking options include a simple overall Naval utility gloss Engine Gray shipboard support version, a USAF Euro II gray green minuteman missile support squadron out of Francis E. Warren AFB (Cheyenne, Wyoming), and two low-visibility three-gray Marine armed versions with the aforementioned warts and weapons, are also up for a decision. And yes, with the different versions, you will be guessing which additional parts to add, including lower FLIR ball, Laser anti-anti-RHAW boxes and antennas, the du-rigeur Cable cutter blades, and a slew of antennas and probes. The kit has an excellent decal sheet, too.

Oh, and on this release, there are three 3-D printed crew members; two pilots, and one crew chief. ABSOLUTELY FANTASTIC detail on these three figures. Primer, paint, and install at your leisure. As they are not part of the actual release, we’ll look at those another time. Let it be known, however, this trend is very much appreciated.

I am unaware if Kittyhawk intends to release an earlier version of the November. For the earlier USAF versions with their standard Vietnam-era two greens and a tan over light gray undersides, through the Experimental war games “polka dot” camo, all would require earlier Vietnam 2.75” FFAR seven-round LAU-19 pods and earlier “minigun in a box” GAU-version with the ammunition box in the center of the cabin. Miniguns (even on low rate of 3000 rounds per minute) chew up a LOT of brass, links, and lead, and there is not an ammo box to be seen anywhere. Hmmmm.

Beginning assembly with the tail boom, the drawings show the Whiskey-model items, complete with all the scabbed on Radome, RHAW, Communication, and antenna bumps. You can look all over the sprue maps for parts, install them, and learn later you DON’T need to have them at all. In the cases I noted first, I had a clean UH-1H/N tail boom, and the drawings didn’t match.

I assembled the tail boom to get that taken care of, then moved forward to the cabin. Use your side-nippers and make sure you clean up the flow gates on the mounting surfaces. I also highly recommend use of new #11 blades. There is no fast way to build this kit. I learned a lot on the “H” to avoid, and the advice on the test fitting and mounting points is the most important.

The one area they fixed was lack of a slot for the floor in the transmission box area in the “H” kits. The floor on the “H” transmission housing now has a locating slot for the tab to go into, ensuring the height of the rotor head is appropriate verses, which we frequently see, a short rotor head height. Look on the net to get a side view of the actual aircraft, and note the swashplate is just above the transmission housing, not sticking a scale foot in the air on a naked shaft under the swashplate, or hidden in the housing itself).

Offering up the interior and other parts such as the lower floor winch and hook to each fuselage half was next up, then we press on with more fun. Be careful with the liquid cement here and line everything up that you can.

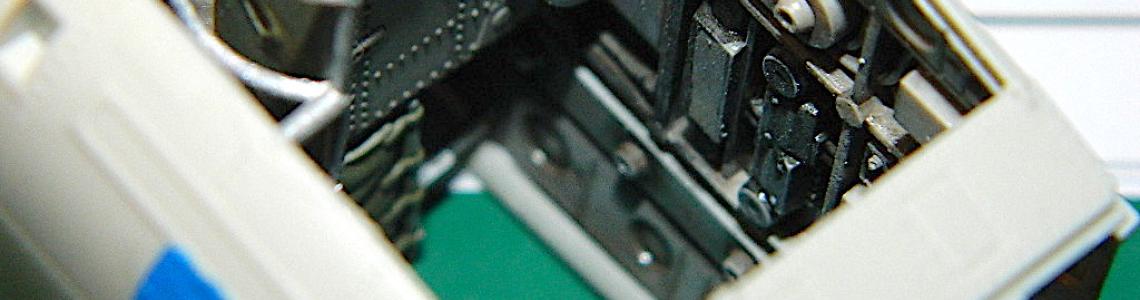

The interior of the kit is extremely well detailed, although there are myriad opportunities for the uninitiated to miss-locate parts due to the modular nature of the kit and associated ‘drill here’ requirements for seats and seat stanchions (aka the floor to ceiling poles that hold everything in place). I basically assembled each of the web seats, and then used a marker and “Mark 1 eyeball” to determine where everything went, drilling holes for the stanchions and inserting into place. One hint here: make sure you install the seatbelts BEFORE you permanently install the web seats in place. There is not a lot of space to put them in situ once the cabin is closed.

I took the remainder of the seat belts and used them on the pilot seats. The over-the-shoulder harness was bent into shape, superglued in place, and then painted.

Center overhead, lower radio, and control panels were all painted black, with drybrushing and “careful 0000 brushwork” handling the switches. The decal for the instrument panel settled in without too much fuss. I have used the Eduard interior set in the past, and still recommend it, but the kit items are more than sufficient with all the doors closed.

The aft cabin has some different options on the seating. This is one area you need to take some time with as it is hyper fragile and poor seats with awful painting will be at the forefront of your work, even if you close all the doors.

Speaking of doors: the side sliding doors are either on or off… and can hide any miss-alignment of the lower engine/fuselage housing if mounted in the open position. I’m certain many of the fit issues I experienced were due to my old age eyes and ham fists, but filler was used in many cases to hide the visible gaps on the engine cowlings, etc. The engines are probably better viewed in a “maintenance setting” with all the doors and covers and cowling open on their hinges. That said, this is the first time I’ve actually seen the intakes and exhaust on any Huey properly given “depth”. The compressor and turbine on these engines is all axial, but on the single engine birds they are axial/radial compressors driven by a turbine. Fact…

The adjustable tail stabilizers fit into their holes on each side of the tail boom. The airfoil side is on the BOTTOM, not top, as they pull the tail down to keep the nose from pitching down at certain attitudes. I glued them in a mostly “tail down” hover position.

Also, the pilot/co-pilot crew doors still have the uber-fragile vertical frame running between the front angle window and the main rectangular window as they are the same as the “H” items off the sprue. The vertical sliding vent section is not provided, so a bit of scribing will fix that. Best way to remove the nasty (but required) runner sprue between the window frames is to use a hot knife; I have YET to successfully remove the sprue without breaking the inner frame. Cleaning up the sprue attachment without breaking the gossamer fragile door frame is a bear, too.

Assemble and do not install the skids at this point. I will state the SAC replacements come in handy, as if you drop the kit at any point having the metal gear may save the build, with the gear bending and not breaking. It happened to me… and they add important balance below the waterline of the aircraft, stabilizing the display and sit of the model.

There are two PE map and document cases to attach from the fret, and they actually fit and do not interfere with door and cabin space requirements. I went ahead and used the provided PE harnesses and belts. Simplistic but still looks better than tape with painted on buckles!

It was about this time I started to close off the doors, install the windscreen and overhead cabin windows. Don’t forget to paint the overhead windows clear green on the inside before installation. I have never seen these as un-tinted clear. Be careful in cementing, because if you allow the fuselage parts to bend in the rest of the fuselage will not fit correctly.

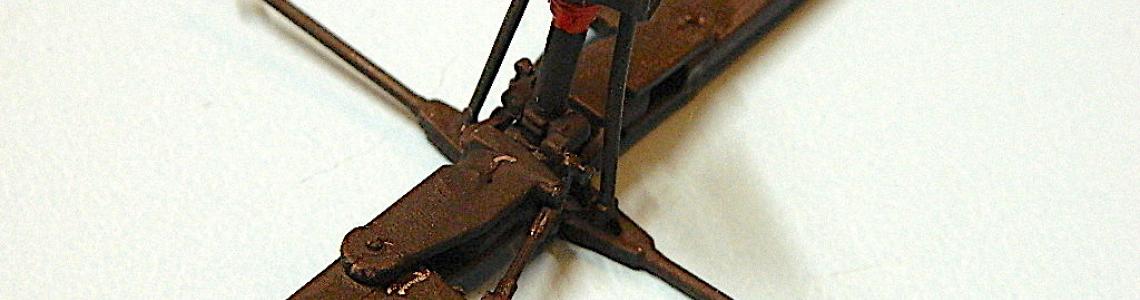

One detail: The tail rotor on all Novembers that I can find in picture land have it as a tractor version, i.e. on the right (Starboard/green light) side of the tail boom. The pusher tail rotor on the left of the short fuselage birds, Deltas, and most “H” proves the “Pull a rope verses push it” theory at work. It’s also more efficient on the right as there is no boom interfering with airflow when in a hover. The pressures are transmitted to the shaft, and it’s “mo betta”.

As stated before the rotorhead is accurate, delicate, and fully detailed. One thing I changed was to cut off the lower shaft below the swashplate and drill out/insert a 1/16” wire rod into the shaft and swashplate to allow it to rotate and not break off the second an overzealous sky pirate tries to fly the bird around the room. Take your time and it all lines up, for the most accurate Huey head out there.

There are two tail rotors provided, an early and late root version with a different rake to it. As I did not notice the later rotor on the bird I’m building, I used the early bird. The pitch controls on this assembly are also very delicate… a warning so to speak.

Leave off most of the antennas until the end of the build, including the cable cutters. Put them on before priming and painting.

After primer painting the kit overall flat white, I noted a few more gaps to fill with “perfect Putty”. Water based, no shrinkage, it was worth the time to do and wipe off the excess. Love the stuff… It actually sticks (although IMO performance of Tamiya is still best when you need a good clean hard surface).

I decided on the Fallon white Navy rescue variant; Painting the yellow tail warning stripe and red/orange scheme was attractive and rather simple. A bit of masking and ready for decals… after which the handhold shaped tail antennas, flat black skids (with PE retaining brackets) and various other bits were added, and I quit. Gloss coat overall to blend in the decals, and hand brush Vallejo flat on the non-reflective black nose and walkway on the roof.

This is not a simple build, but I’m thankful to Kittyhawk for doing these kits. The November is a great effort and looks almost perfect on the shelf flightline! Rated “8” for parts fit, 10 for subject, overall 9. This is a great improvement over the “H”, but some of the same problems exist with this new release, and the combined (but unannotated changes) kit instructions demand some expertise on the actual aircraft for most effective presentation. The only real complaints I have, as stated before, are the instructions. It’s a relatively cheap improvement to increase sales!

Thanks to Kittyhawk for the review kit, and also to the reviewer corps leadership for the trust shown to my building skills!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews