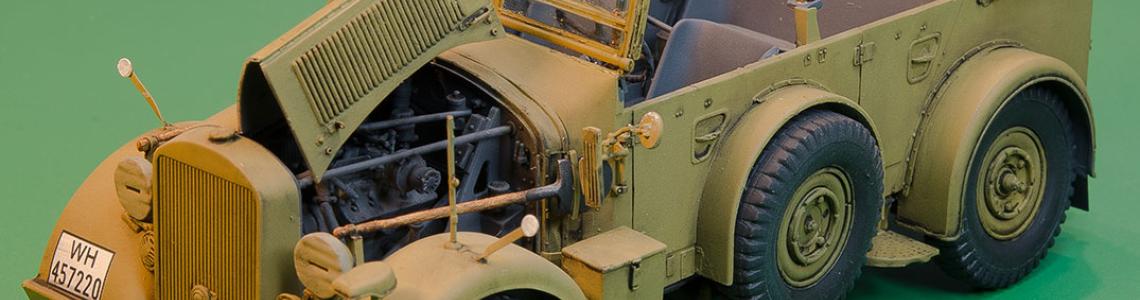

Mittlerer Einheits PersonenKraftwagen (m.E.Pkw) K fz 12 (Early Version)

The Einheits-PKW (German for 'standard passenger cars') were supplied to the Wehrmacht between 1936 and 1943 in the three versions Leichter Einheits-PKW, Mittlerer Einheits-PKW and Schwerer Einheits-PKW (light, medium and heavy passenger car). These vehicles were supposed to replace the civilian vehicles previously procured by the Reichswehr with cross-country mobile vehicles that conformed with military requirements while simplifying logistics and maintenance by using standardized components. The program achieved neither of these goals. (Source: https://www.wikipedia.org) However, if your goal is to build a very highly detailed model in 1/35 of this vehicle (the Kfz 12 version included a tow bar), then this Bronco kit definitely delivers.

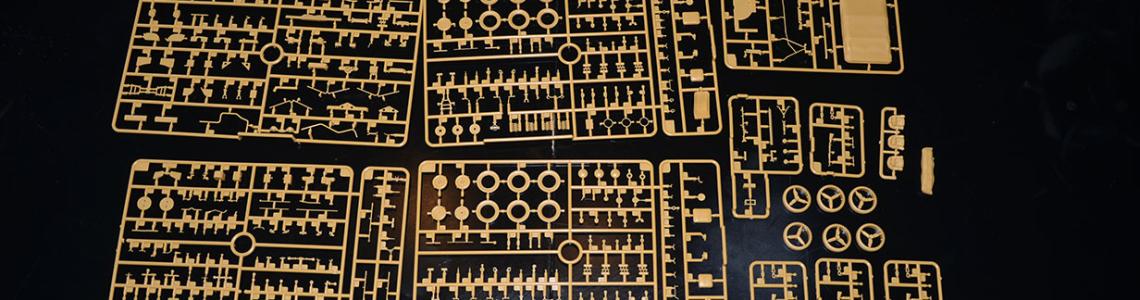

Parts

- Molded in desert yellow styrene: 573

- Molded in clear styrene: 12

- Photo-etch fret: 1

- Decal sheet (markings for 5 different versions)

Bronco brings us the Kfz 12 in 573 desert/dark yellow molded styrene parts on 17 separate sprues (33 are marked in the instructions as not to use) with an additional clear parts sprue with 12 parts. A photo-etch fret is included with a respectable amount of PE on there. Unlike other kits there is no substituting styrene for brass or vice versa. This is an advanced kit for the advanced modeler. The kit also utilizes bolts molded onto one of the sprues (so, in fact, there are more than 573 yellow styrene parts) that you are to shave off with a sharp blade and glue onto various points on the suspension/frame.

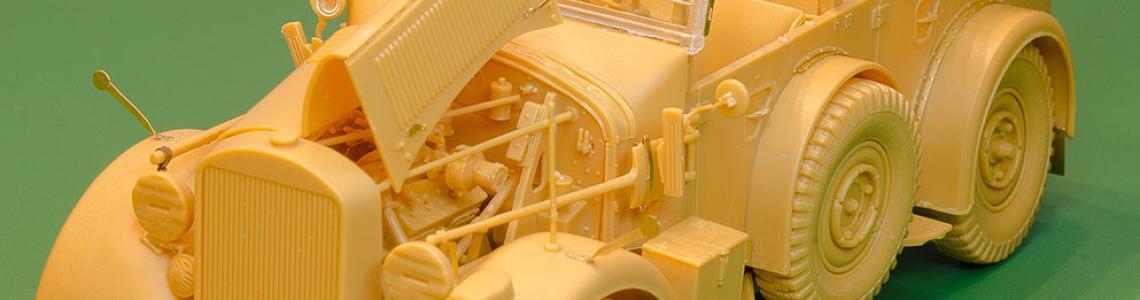

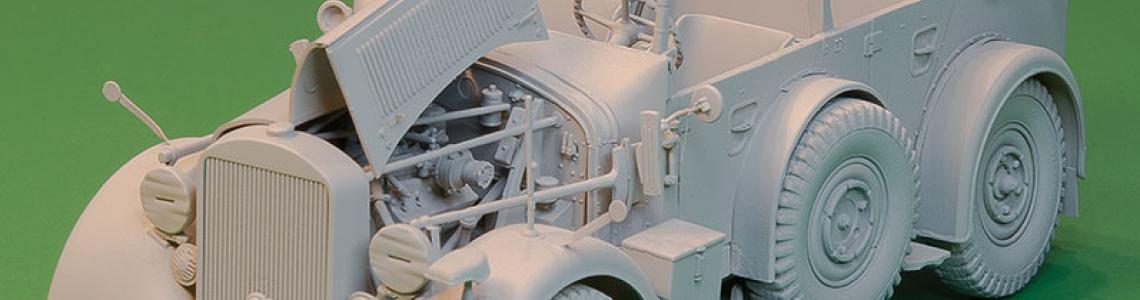

The molding is clean and there is minimal flash on any of the parts and only a few needed minor clean-up. Some high points in the kit are individually molded-in-styrene suspension springs…very impressive (see pic 03). When attached correctly they give the vehicle a bit of bounce. Small detail continues even with finely molded rods that might actually do better by replacing with brass rod/wire in order to provide more strength (see pic 04). However, since I was doing a review I wanted to utilize all the parts provided via the kit. This is particularly evident on the cross-support rod behind the front seats that helps keep the side walls of the vehicle from warping inward. On my kit this piece snapped due to the pressure and the side walls do warp inward a tad bit. One downside to all this detail is the great care needed when removing the small parts from the sprue: think about and have in-place a plan to catch the parts as you cut them.

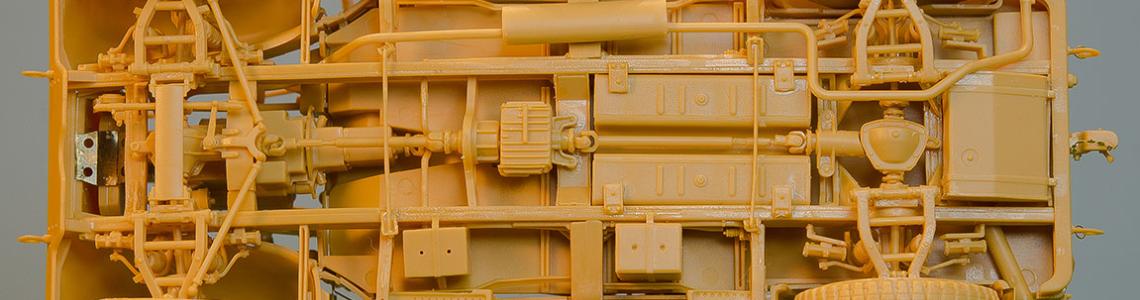

Overall fit of all the parts was quite good and no major filling or sanding was required. When constructing the wheels great care must be taken when sanding down the sprue attachment points on parts G2 inner tires as these parts are perfect circles that fit inside the larger G5 outer tires. If sanding down too much it will create an unrealistic gap which then must be filled. In the two times I did this it was easily filled with Vallejo plastic putty as excess wipes away easily with water and a Q-tip.

Engineering of the kit is sound albeit complicated. I would recommend treating each subassembly as a kit in of itself. For example, each wheel has its own suspension subassembly that is engineered quite well. If you take your time and pay close attention to each of these then the overall engineering of the kit will shine (reference my comment above about the individually molded springs). If you rush these parts, all four wheels might not touch the ground at the same time, and the engineering is wasted. Speaking of wheels and detail, each one consisted of 8 separate parts.

Pay particular attention to the position of the frame (front/rear, top/bottom) during construction. In the instructions it changes from step-to-step. Pick a reference point (like the front or rear bumper) and keep it in mind, and continually double-check during the initial steps of the build. Doing so will help you keep the parts glued in the right spots.

Ejection pin marks are minimal and smartly located. Only in spots where both sides of a part are visible is where you will run into trouble. For example, the side walls of the vehicle have visible pin marks on the inside and if you build the vehicle open-top you will have to contend with these.

One surprising yet unwelcome aspect of a kit with this level of detail is the molding of the windscreen glass and frame (as well as side windows/frames) as a single clear piece. This means that you have to mask and paint this clear piece…which can be challenging. I would have hoped for a frame I can paint followed by the application of clear pieces to said frame. On the bright side, I was able to practice my clear-piece masking and painting technique: sealing the Tamiya tape on the clear piece with a couple layers of Pledge Floor Care (formerly known as “Future”) before applying your color as this keeps the paint from running underneath the tape.

I primed the vehicle with Tamiya surface primer and while I am usually a Tamiya loyalist I utilized Vallejo paints for this build. A primary reason for this is I wanted to get in more practice with these paints. Another reason is that the version I depicted with this build is a Kfz 12 serving in North Africa with the 220th Armored Recon Det. One of the primary colors used by the DAK up until mid-1942 is RAL 8000 and Vallejo Model Color 70.879 “Green Brown” is listed as this very color. In order to airbrush it I had to heavily thin with Vallejo airbrush thinner but the end results were very satisfactory. Other Vallejo colors used were all from their Model Air line and all sprayed very well through my .35mm Iwata Eclipse. I minimized the weathering that I usually apply to my armor subjects since the goal of this build was a review and I wanted to show the completed kit as clean as possible. The only weathering I did do was an oil pinwash. This is in order to highlight some of the excellent recessed and raised details of the kit. In addition to the oil pinwash I also utilized oils over acrylic for the wood on the tools and rifle stocks.

Decals are the only low point with this kit. I soaked the decals for no more than a minute in warm water and a couple of them immediately started to disintegrate upon my moving them off the paper with a toothpick. Even with less soaking time (approx. 15 seconds) they were lifted off the paper easily but still were susceptible to breaking.

Overall I spent 35 hours on this kit with a whopping 25 dedicated on the build alone. If you are up to the challenge and looking for the satisfaction that a complicated build gives you, then this is the kit for you. I can only recommend this kit for advanced modelers or, at best, an intermediate modeler who is looking to up his or her game and practice on something more complicated than a Tamiya or Dragon kit. Many thanks go to DragonModelsUSA for providing IPMS USA with the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews