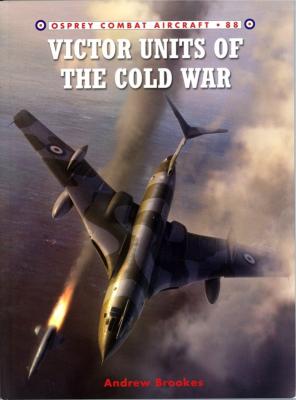

The Victor was the second of the three “V Bombers”, Valiant, Victor and Vulcan, flown by the RAF in the nuclear strike role. When Surface to Air Missiles came onto the scene, the Victor became a low-level penetration aircraft. With the advent of the Blue Steel stand off missile, the mission became more feasible, but still sporty. This is when the camouflage changed from white overall to grey/green upper surfaces.

Welcome to IPMS/USA Reviews

Introduction: The primary organization of the IPMS/USA Review website is by IPMS/USA National Contest Class. Within each Class there are sub-menus by kits, decals, books, etc. The Miscellaneous Class is for items that are not class specific or that cross two or more classes.

IPMS/USA Members: We encourage you to submit reviews, both here and to the Journal. To volunteer for membership in the IPMS/USA "Reviewers Corps" and submit your own reviews, please read the Guidelines For Submitting Product Reviews.

Manufacturers, publishers, and other industry members: IPMS/USA is pleased to offer your company the opportunity for product reviews. All product reviews are performed by IPMS/USA members, and are posted in the publicly-accessible section of our website. With very few exceptions, we perform full build reviews of new kit releases, aftermarket products, and supplies. If you would care to provide product samples for review, please contact John Noack, IPMS/USA 1st VP.

To learn more about IPMS/USA, please see our About Us page.

After producing several 1/400th U-boats, Mirage is now offering U-boats in the increasingly popular 1/350th scale. The U-511 was a Kriegsmarine long-range IX-C type submarine. The Turm-I variant included trial installation of a six tube Wurfkörper 42 artillery rocket launcher rack and improved 37mm and 20mm anti-aircraft armament. The kit features a 2-piece full hull, detailed exterior surfaces, conning tower with 2 periscopes and wintergarten, 10.5cm deck gun, display base, photo-etch parts (railings for all deck levels, anchor, cable cutter, WGr42 launcher base, ladders, screw blades and nameplate), and decals (U-511 bow placards and ensign). The completed model is approximately 8.6" long.

Introduction

"Steampunk", according to Wikipedia, "...is a sub-genre of science fiction, alternate history, and speculative fiction that came into prominence during the 1980s and early 1990s..." and "...involves an era or world where steam power is still widely used—usually the 19th century and often Victorian era Britain—that incorporates prominent elements of either science fiction or fantasy." "Works of steampunk often feature anachronistic technology or futuristic innovations as Victorians may have envisioned them; in other words, based on a Victorian perspective on fashion, culture, architectural style, art, etc. This technology may include such fictional machines as those found in the works of H. G. Wells and Jules Verne or real technologies like the computer but developed earlier in an alternate history." You can read more about it at http://en.wikipedia.org/wiki/Steampunk or just search the web.

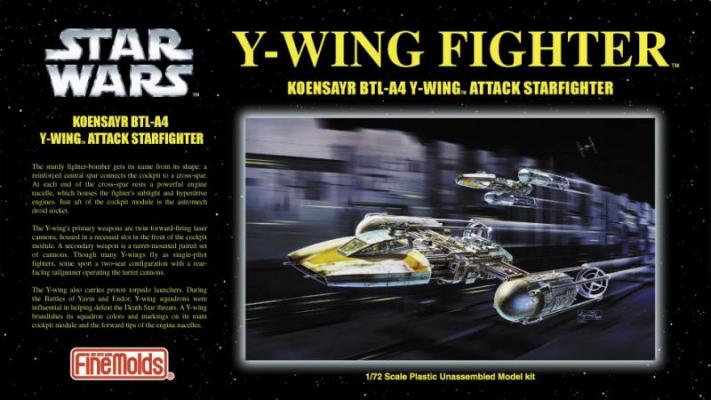

Editor's note: Dragon Models USA is the Fine Molds Models Importer in the USofA but this review author provided his own kit, out of pocket, for this review. The kit is currently very difficult to find on the retail market.

Pros:

- Superbly engineered kit, very little filling or correcting will be needed.

- Best kit of this subject ever released.

Cons:

- Expensive, now increasingly hard to acquire. (I apologise for teasing you with the review)

- Instructions in Japanese (note: may not actually be a con if you *are* Japanese)

Overall

A pricy kit but you get what you pay for in this case. Given the cost and the fact that viable alternatives are around, this not for a casual SW fan or model builder. Instead, this kit is for somebody who wants to do a really nice job on a Y-Wing fighter with a maximum of detail and a minimum of grief.

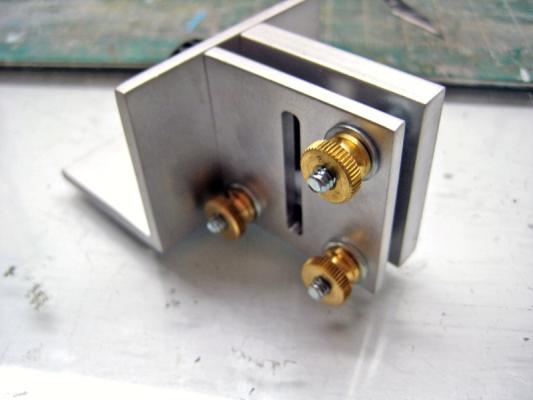

I love tools. I don’t think you can have too many. Occasionally I come across one that I say "how did I live without that?" That is what this tool is. More than a simple jig, this machined metal tool allows you to flat sand the bottom of the wheels evenly and consistently. Let’s face it a perfectly round wheel is not realistic nor are the flat wheels that are common on aftermarket wheels. That is where this tool comes in, the perfect balance of weight without being flat.

How do you use it? Simple get your tire from the kit, clean up the seam lines, set the angle, clamp the wheel between the flat spots on the tool and leave about 1/8 inch out the bottom. Then simply sand with 320 sandpaper while applying pressure to the base plate. It is that simple, but does it work?