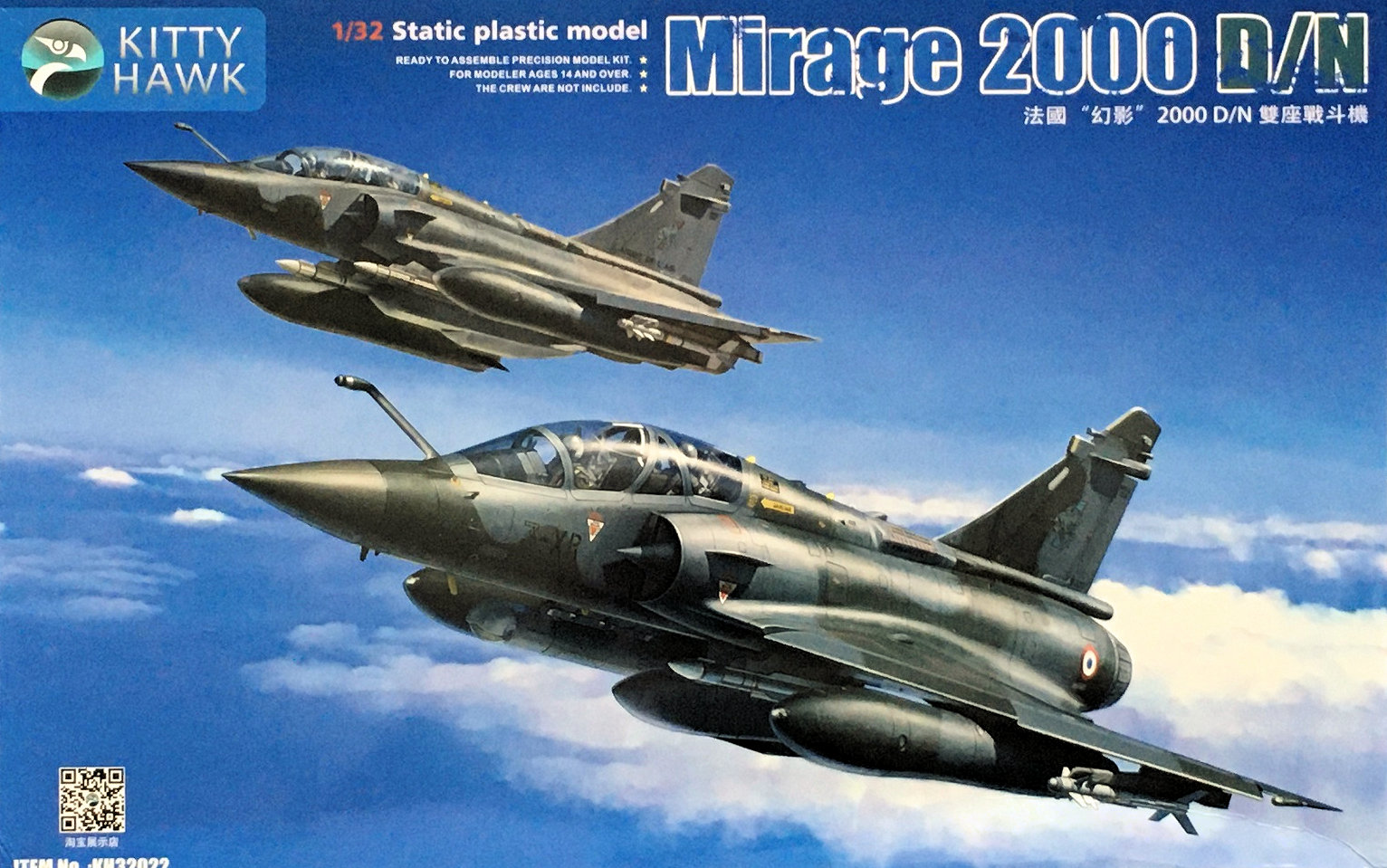

Mirage 2000 D/N

The Dassault Mirage 2000N is a nuclear strike variant, while the 2000D is a conventional attack version of this versatile French fighter. It has seen extensive and distinguished action in the Middle East and other parts of the world.

The Mirage was packed in a large, strong and colorful top opening box. Each sprue was contained in its own plastic bag. At the bottom there was a separate cardboard box protecting the clear sprue, a resin exhaust nozzle in a small zip lock bag and the instruction manual. The decal sheets were found in their own zip lock bag along with a photo etch fret. The complete package was superbly done and offered maximum protection of all parts. Only the two main ejection seat parts were loose from their sprues.

I had read other reviews on Kitty Hawk models that the instruction manual was the main weak spot in their kits. I studied the instruction manual to become acquainted with the model and noticed a few things. The presentation was very nice and appeared easy to follow with uncluttered, modular steps. However, as I progressed through the build, I found some confusing presentations in certain construction steps and needed to refer to the next steps to clarify what needed to be done. There were absolutely no color call outs for any parts throughout the build leaving the modeler to do their own research. Many parts were miss-numbered, but, typically it was where there were two similar parts. A little thought and searching of the particular sprue was all that was needed to find the correct part.

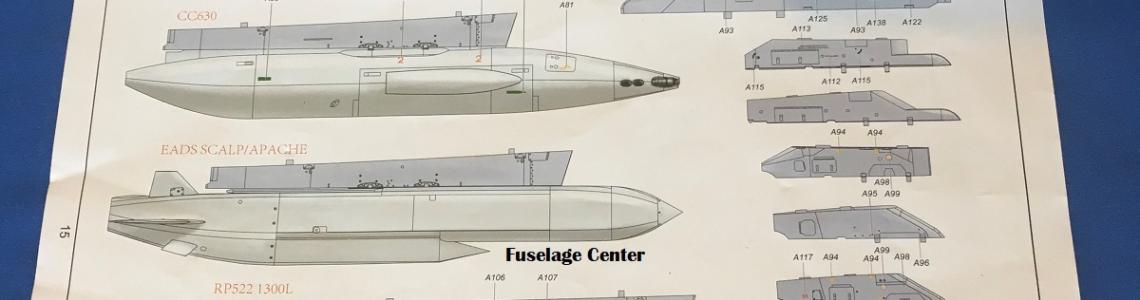

At the end of the manual was the assembly of all the weapons, targeting pods and fuel tanks. The separate color weapons diagram named each one. It also indicated some of the pylons they mount onto. The weapons stencil diagram and all the plastic sprues were taken from the previous boxing of the Mirage 2000C which included all the stencil decals. There were no weapons, pylon or tank stencil decals included in this kit! Rod Lees, who recently reviewed the Kitty Hawk 1/32 Mirage 2000C was super kind and sent me the complete weapons stencil decal section from a second Mirage he had bought. Thank you so very much Rod!

A very nice aspect of the instruction manual was the glossy color, center pull out pages showing all the different aircraft that can be built with marking and airframe stencil decal placement and color callouts (Some dubious).

The model’s construction was straight forward for the most part and many sections could be built as sub-assemblies. I very much liked that the sprue stubs attached to the mating surface instead of the visible outside edge on most parts. I did have to be careful trimming the remnants of the stub from the part, but, this method resulted in no damage to the lovely recessed surface detail.

Another aspect of the superb engineering of this model was the fact that there were no ejector pin marks anywhere that would be visible! However, on the back side of a lot of parts were ejector stubs that needed removing, but, cleanup was easy and again these would not be seen.

From internet research and other online builds of this aircraft in different scales, I used my best judgement on what color to paint various parts as I went along.

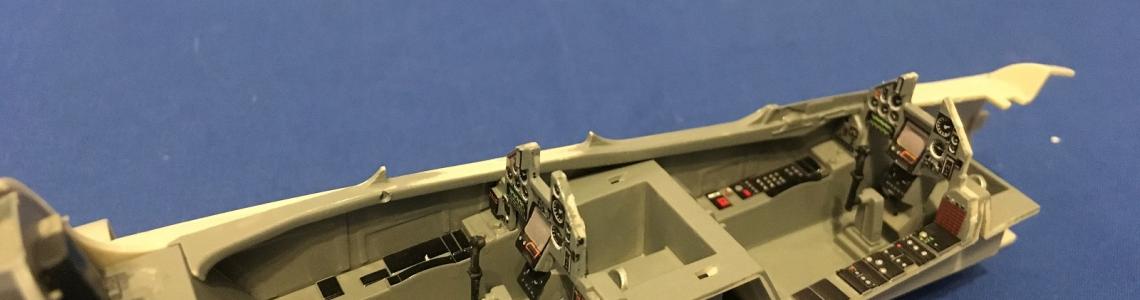

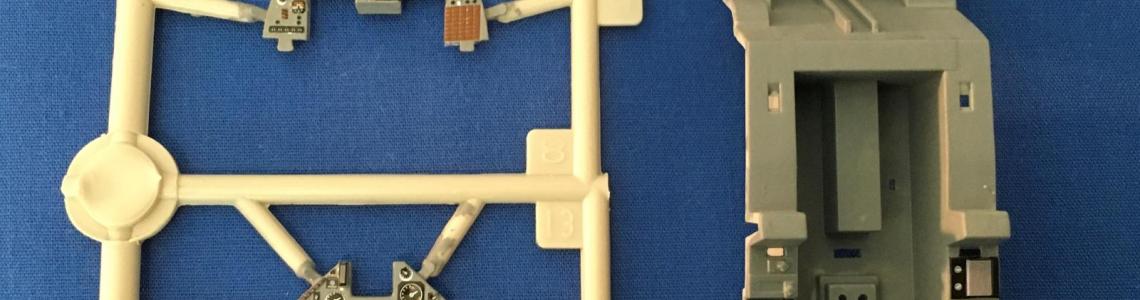

I started construction with the cockpit. The cockpit “tub”, instrument panels, side walls and other parts were assembled and painted Model Master dark gull gray. There are decals for the instrument panels and side consoles, but, none of them were accurate for the 2000 D/N versions of this aircraft! There were virtually no switch details on the rear cockpit side consoles and the front cockpit appeared to be the same used in the previous 2000C, which was quite different to the “D”. The prominent throttle levers in both cockpits were missing as well. I scratch made these from plastic sheet and a small section of round sprue. These were painted red. As no aftermarket cockpits or photo etch were available in this scale, I used what was given. For such a stunning kit, the lack of attention to such a visible part of the model was a true letdown! There were no references to using the cockpit decals in the instruction manual either. On a positive note the decals laid down nice and accurately over the surface detail with the help of a little Micro-Sol solution.

The ejection seats, on the other hand, were quite nice with good detail. The kit supplied photo etch harnesses were fine, but, the fifth belt that ran from the front of the seat, up between the pilot’s legs was missing. I made these out of tape and plastic sheet that I punched out as circles for the buckle. I used online photos to paint the seats.

Both engine intakes were built next and each part fit together precisely, except for two blow in doors on each intake. The kit supplied doors were way too small, so I scratch build the doors from Evergreen plastic sheet. There were no full-length intakes, but, very little can be seen, so this was not an issue for me. I did not install them until a little later.

A reasonably detailed SNECMA M53 turbofan engine was included but it had no means of being displayed outside the airframe. A compressor fan fit over a second compressor disk and looked great. The two-piece exhaust pipe exhibited good detail and the turbine face and afterburner ring finished off a simple, but effective, looking exhaust area. Both the compressor and exhaust sections sandwich between the two engine halves. I assembled all the accessories attached to the outside of the engine and painted everything I thought might be visible dark gray. To complete the exhaust area, a lovely resin exhaust nozzle is supplied, which I installed at the end of the build.

The nose wheel bay, fuselage and wing parts of the main wheel bays need to be assembled before the fuselage is closed. Each showed outstanding detail. Everything was a tongue and groove fit and went together nicely. The nose undercarriage leg had to be attached at this stage also. While the plastic landing gear was more than adequate, I used the SAC white metal undercarriage. Even though one of the mounting axels was square, the nose leg could be gently coerced into the retracted position and out of the way for now.

I deviated from the build sequence and added the top half of each wing to their respective fuselage sides before joining the fuselage halves together. Two large tabs on the wing root slot into the fuselage and were extremely tight. A little thinning helped obtain a better fit and ensured the wing root fillet sat flush against the fuselage side - no filler was needed. The underside wing halves were then added. I took my time to get each wing half perfectly aligned, and with the help of rubber bands and Tamiya cement, ensured a great fit.

In steps 36, 37, 40 and 41, the instructions show fitting the elevons and flaperon control surfaces before the hinge fairings. I found it better to attach the hinges first which took guess work out of positioning and aligning of the control surfaces.

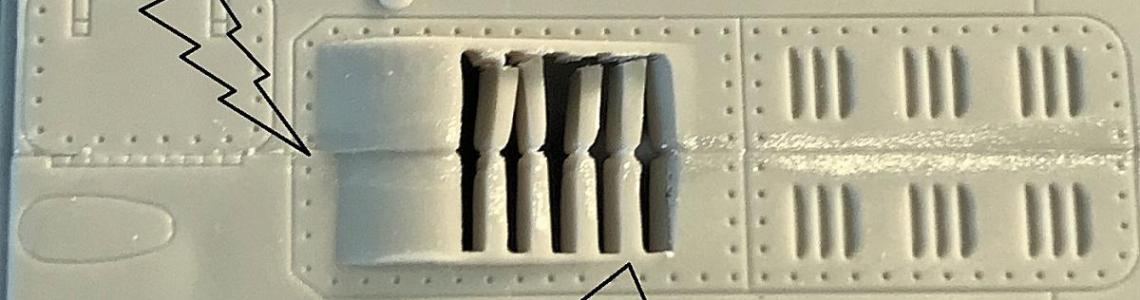

The engine, wheel bays and cockpit, minus seats were attached to one fuselage half. Two vents were glued into the belly. These were numbered wrong. Also, two small windows were added in the upper fuselage. These needed trimming to fit better. Paint the inside of these aluminium or steel.

The engine attached to the fuselage via four small pins that were a little tricky to line up. Once they were lined up, the fit was fine.

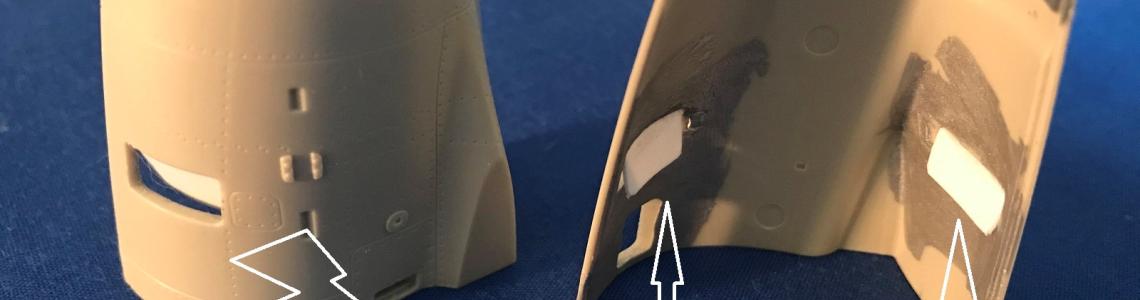

Both fuselage sides fit together well. Extra care was needed when gluing the belly halves as there was a lot of panel line and hatch detail running through the seam. Luckily, the pylon I chose to use hides much of the seam. I replaced the louvers in a vent behind the nose gear bay with Evergreen sheet cut into strips, as the kit louvers joined in the middle with seams that were difficult to eliminate. The front of the forward belly vent on one fuselage side was shorter than the other requiring careful adjustment.

With the fuselage glued together, I attached the engine intakes. The fit was so good, all I needed was a thin line of Tamiya liquid glue along the seam and they were done!

There are two nose cones provided – one with lightning bars and one without. I used the former. A rudimentary radar is provided, but I didn’t use it.

I don’t know if nose weight was required and there was no mention of using any, but, I added some lead just in front of the cockpit for good measure.

I turned my attention to the main undercarriage. Again, I used the SAC white metal legs and retraction struts, plus plastic torque links parts required from the kit. The SAC undercarriage set was sent with the Mirage model and reviewed separately. The main and nose wheels show very nice tire side wall and rim detail, but, no tire tread. I unsuccessfully attempted to scribe in the tread pattern with my razor saw. Resin wheels are available, if needed, from Res/Kit (I ordered a set). I did not install the mail landing gear until later.

The tail includes four optional tips containing different sensors, but, no reference as to which one to use. I looked over the now separate decal and painting diagram of the aircraft I intended to build and used what I saw there (all were the same). I also found a picture of the same aircraft online and verified the tail tip was the same. Each tail piece was one piece and fit together ok. There was a slight mold misalignment at each mating surface, so some careful sanding was needed to eliminate them and improve the fit of both of these parts and the fit to the fuselage. A position light was meant to fit into either side of the tail tip, but, they were not included on the clear sprue. The instruction showed part numbers GP12 and 13, but, these were two totally different parts! I filled the hole with Testors clear cement and went on!

Once the basic airframe was finished, I spent some time researching what weapons, fuel tanks and targeting pods the “D” version would typically carry. There was quite a lot of information on the web and some great pictures. There were nine hard points: two under each wing, four on either side of the fuselage (fore and rear) and one on the belly centerline. I loaded my Mirage with two RP541/542 2000 Liter tanks, one EADS Scalp/Apache cruise missile, one PDL-CTS targeting pod, two Matra Mica EM Missiles, two Matra Super. 530 missiles and one Matra R550 Magic 2 missile. Modifications were needed to mount some of the stuff that goes “Bang”!!!! Refer to the pictures to see where each one was mounted.

An AUF-2 dual bomb carrier was included, which was a common load for the 2000 D, but, no bombs were included. Aftermarket bombs are available, but, I didn’t bother.

The fuel tanks and weapons fit together very well. Some slots for the fins were a little too tight and needed opening a bit. This was certainly better than too loose and aided in proper alignment.

I was impressed as the pylons were all one piece each – No gluing two haves together and no sink marks! A quick swipe with sandpaper took care of any mold seams.

The aircraft, tanks and weapons glue seams were taken care of and the whole lot was prepared for painting.

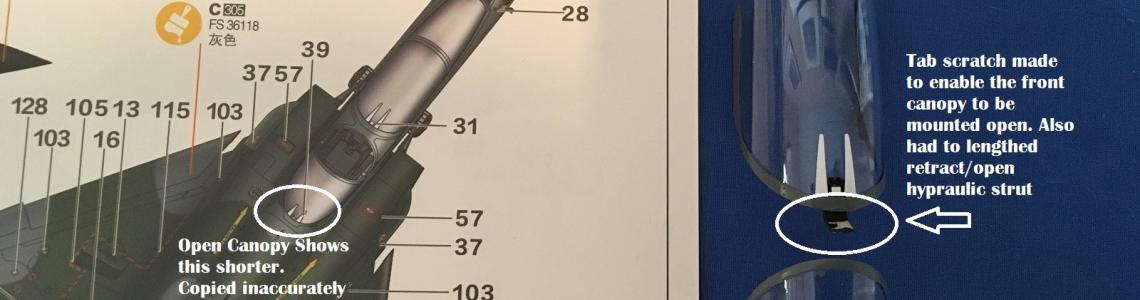

The canopies were nice and clear, however, they all had a seam line running through the center that turned out to be a ridge from a mold misalignment. I sanded down the mold line followed by polishing and a dip in Future Floor Wax to protect them further. The seam line was only on the outside of each canopy. There were three canopies on the clear sprue. One is clearly for the previous 2000C model. All canopy parts were numbered wrong.

The rear canopy had two hinge tabs that allowed it to open and close, but, the front did not. The front canopy should have the same hinging setup as the rear. It is obvious Kitty Hawk intended the rear canopy to be posed open and the front closed. I attached a portion of flat sprue to the rear inside of the front canopy and angled the back of it so the canopy could be mounted open. I also had to add a length of wire for the retraction strut to reach the open canopy.

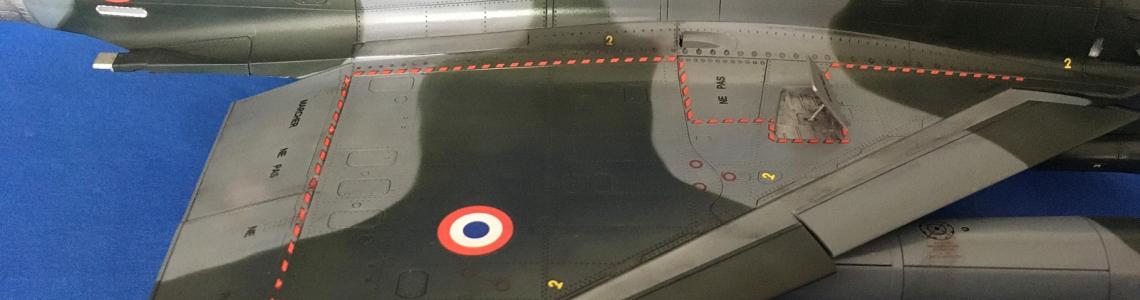

I sprayed the model with Tamiya neutral grey and black green with soft edges. The nose cone was painted with a muted black green and left flat. A gloss coat followed.

There are nine French marking schemes offered with most being quite colorful representing various anniversaries and special events. I chose the basic version on the box top as I wanted a standard squadron aircraft that showed the graceful lines of the “Flying Stiletto”.

Some of the special markings are inaccurate, for example “Tiger is Coming” should have the tiger on the left side of the tail and a map of Europe on the right. Kitty Hawk has the tiger on both sides. On another aircraft, the Devil and bird option is on the left and should have a large Indian Chief on the right side, as opposed to the Devil on both sides. Nevertheless, if the modeler is not worried about absolute accuracy these marking will certainly look spectacular.

Interestingly the weapons stencil decals that Rod sent me were overly thick and needed much help to lay into panel lines, but, they were in good register and color. The color bands that ran around the various missiles were all too short requiring me to position the “short end” where the missile met the pylon to try and hide it. In the end they all looked good under a couple of clear coats. My 2000D kit decals on the other hand, were very thin and wanted to fold over on themselves. Once folded over they were stuck fast and took a great deal of care to separate. I was lucky and did not lose any decals. Some decals were pixilated and many were a little out of register. I applied Micro-Sol after placing the decal and achieved good results. Any minor silvering was taken care of with more Micro-Sol and poking with a new blade.

The decals were sealed with another gloss coat, followed by a panel line wash. Another semi-gloss coat and some touch up completed the painting.

There was still a lot more work ahead with the final assembly of all the parts I painted separately. Most of these parts went together quite nicely.

Be particularly careful of the inner main undercarriage door retraction strut/bulkhead assembly. I found it easier to sand down the tab on the top of the bulkhead a bit so it would slide (with some force) into its slot in the undercarriage bay roof. This part would be easier to assemble when building the bays before attaching them to the fuselage, although the retraction strut is very fragile and could be broken. I wanted my doors open, but, most internet pictures show these doors closed on the ground.

The main undercarriage legs, retraction strut and doors were attached and fit nicely. I lowered the nose gear, glued on the torque link and landing lights and positioned the leg in the correct position with the retraction strut. The nose gear doors were then glued in their position and the aircraft could finally sit on her feet. The rear nose gear door is typically closed on the ground, but, the kit nose door, like the main inner doors are designed to be posed open. With the lovely detail in both main and nose gear wells it would be a shame to close the doors.

The leading-edge slats and guide rails were attached. The rails slotted into the underside of the slat but were a little tight. I trimmed them for a better fit. These were then mounted to the wings in their down position. There are two per wing.

The five fuselage weapons pylons were glued in their slots, followed by the wing mounted pylons. I had to modify most of the pylons to accept the missiles I chose to use. Wire was inserted into holes I drilled into the pylons and weapons for a stronger attachment. The two external fuel tanks were also glued to the inboard wing pylons and required no modification.

The final assembly included antennas and several navigation lights fuselage roof and belly. The canopies were attached open.

There will also be plenty of spare parts to use on future French aircraft models.

The Mirage 2000D is certainly a very beautiful looking aircraft and in my opinion the two-seater is even more aesthetic that the single seat 2000C.

Despite my frustrations with so many errors in this kit, I thoroughly enjoyed building it. The model fits together quite nicely and looks to be accurate in shape to the real aircraft. I believe the modeler needs to use some common sense and research the aircraft you want to build before starting and during the build…That’s half the fun of building these kits, right? To learn more about the subject and help other modelers where needed! However, I would not recommend this Kitty Hawk model to less experienced modelers even though it was not overly difficult to build. The errors in the instructions and ambiguity in some building steps, even had me scratching my head a few times!

I would sincerely like to thank Kitty Hawk and the IPMS USA for entrusting me to build and review this Mirage 2000D.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews