USMC F-4J Phantom II "VMFA-333 Fighting Shamrocks", Part 1

Academy has released a re-boxing of their 1/48 scale F-4J Phantom II, this time with markings for VMFA-333 “Fighting Shamrocks” and VMFA-232 “Red Devils”. The first boxing of the Academy “J” variant was in 2014, and this re-boxing was produced in 2024.

In the Box

The kit is enclosed in a sturdy box and each sprue is enclosed in its own plastic bag, except for the ones that are doubled up, primarily the ordnance. The sprues are injected in three colors (gray, white, and black) and one clear sprue for the windscreen, canopy, and light parts.

Instructions are well-illustrated and easy to follow, containing 17 steps for assembly completion. It is worth noting that on the last page (parts location diagram) in the bottom right corner, in very small print, is a list of parts NOT used for the “J” variant. During the assembly process, you will notice a lot of parts left on the sprues and wonder if they are being used or not. These notes will help to inform you immediately whether they are going to be used or will become spares.

For painting reference, several companies are listed in the paint guide and will be helpful for those who have a large paint inventory. One company that is missing from the list is Tamiya, but there are plenty of online resources for any cross-referencing if needed.

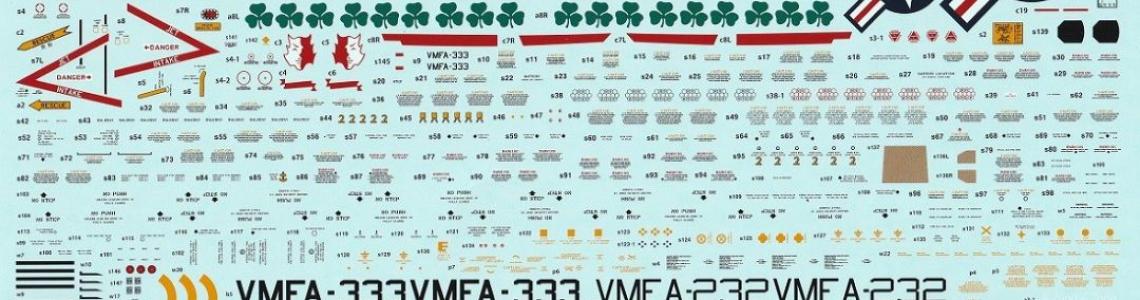

Decals are printed in Italy and looked to be done by Cartograf, though not officially stated so in the fine print.

Markings include:

- F-4J BuNo. 155852, AJ202, VMFA-333 “Fighting Shamrocks” USS Nimitz (CVN-68), 1976-77

- F-4J BuNo. 155523, DN113, VMFA-333 “Fighting Shamrocks” 1978

- F-4J BuNo. 155818, WT2, VMFA-232 “Red Devils” Clark Field, Philippines, 1974

Review Process for Part 1

This is a box stock build with no added aftermarket items; however, I did take some liberties with the assembly sequence and used the kit’s sprues to help shore up some areas. Academy has you starting in the cockpit, but I chose to start with the ordnance. This way as I get closer to the end of assembly, the ordnance is ready to be installed versus the drudgery of being the last parts to be hastily assembled and completed. In addition, there is the repetitive task of completing many duplicate bombs and missiles, which could add to the monotony.

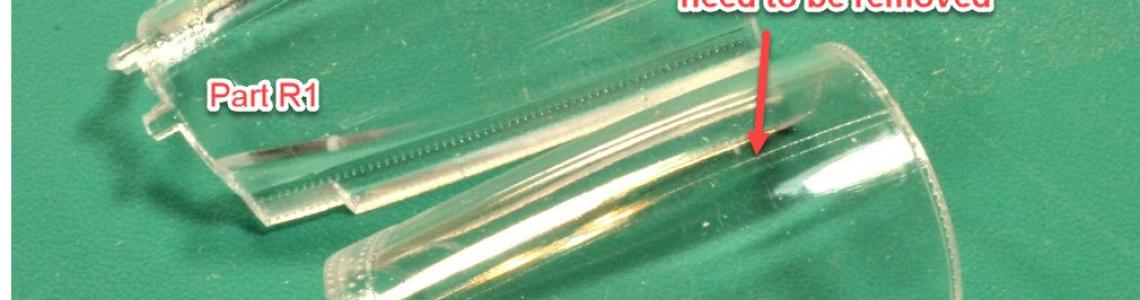

The clear parts have a centerline mold seam on the canopies. To fix this, I scrapped off the raised edge with a hobby knife, and then I wet-sanded, starting with 600 grit and stepping up to 10,000 grit sandpaper. I finished with an application of polishing compound as the last step to help create a clear finish.

Once the canopies were finished, I turned my attention to the biggest part, the upper fuselage. Upon inspection of this part, you will notice it is created using slide molding to obtain good rivet and panel line detail on all the surfaces. This, however, does create some seam lines in less obvious areas and will need some light sanding to remove some minor flash. The next area of attention was the holes that must be drilled in the lower wing if you plan on attaching ordnance or fuel tanks to the underside (Step 5 & 7).

The cockpit area is a straightforward build with no surprises. The instrument and side panels are molded with raised detail and are very well appointed. There is no decal to add color to these areas, so I applied Vallejo acrylics to give it some life. I also decided to add pilots to help add a human touch to the cockpit.

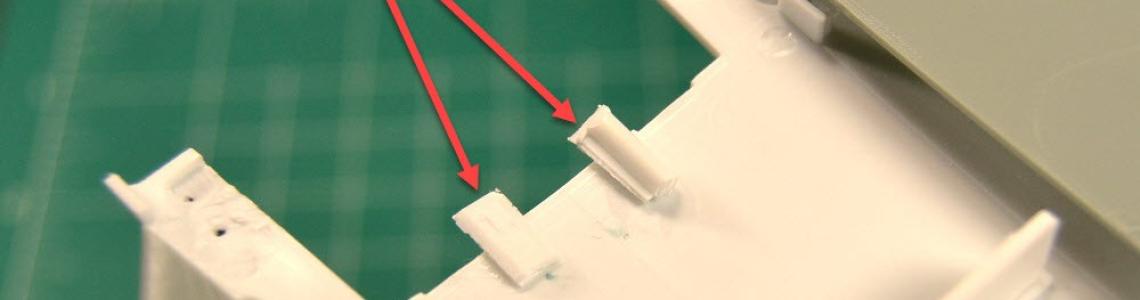

The next area I tackled was the intake trunks. The aft portion of the intakes are made with two white plastic parts (F1 & F2, F2 & F4), and a seam is left at the top and bottom. I filled the seams using CA and sanded them smooth and then airbrushed flat white. This is where I deviated from the instructions. Using the splitter plate (G23 and G22) as a guide, I installed interior aft intakes (Step 6d & 6e) to the forward intake trunk, G40 and G41. This removed any outboard gaps in the intakes. I did leave the step inside since it was difficult to access. I also added flat sprue tabs to the upper fuselage in the area where the wing meets the lower part of the intakes to ensure a flush surface mount could be obtained later in the assembly.

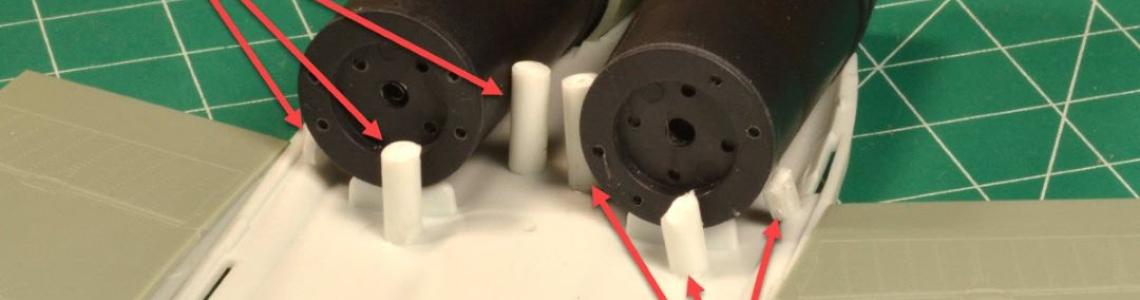

Another area of deviation was the exhaust stacks. The instructions have you install them in Step 7 prior to the upper fuselage being attached to the lower wing. I wanted to install the exhausts much later in the build to allow easier painting for the rest of the jet. To help in this matter, I took some sprue and attached it to the lower wing interior to assist in aligning the exhaust. While not a big effort, it does help in the exterior painting process.

During assembly, the upper fuselage and aft lower tail (Step 12) did not mate up evenly when butt-joining the parts. To fix this. I added sprue to spread out Part O1 to mate with part O2. I then added sprue to spread out the upper fuselage to mate up with O1.

When joining the upper fuselage and wing together, gaps less than 1mm wide appeared. To remedy this, I added sprues to widen the lower fuselage to remove those gaps. These deviations and fixes made for an easier assembly with little putty required to fill any gaps. This also allowed painting the model to be much easier. At the time of this unboxing review, the build is about 75% complete and PART 2 will be a review of the completed model.

Conclusions for Part 1

This is a great kit to build. Not too hard, but not simple either, and with great surface detail. Some patience and effort will be needed during assembly since this is a 1/48 scale kit.

I want to thank MRC and Academy for providing the F-4J Phantom II kit and the IPMS/USA for allowing me the opportunity to perform this review. I highly recommend this kit to those who have a few kits under their belt and the finished build review will appear in Part 2.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews