SMB-2 Super Mystere

Manufactured in the Czech Republic Special Hobby produces a number of high-quality scale model kits. This one is in 1/48 scale of the Israeli SMB-2 Sa’ar (Storm in Hebrew) Super Mystere used by the IDF seeing action in the 1973 Yom Kippur conflict. Originally produced by Dussault, and upgraded to carry the Pratt and Whitney J 52 engine that also powered the A-4 Skyhawk. This extended the already worn-out airframes, increasing their performance and survivability in the process. They were retired from front line service in 1973.

The kit is molded in light grey plastic on seven sprues, 2 of which are duplicates. A sprue of clear parts also is included. The kit also contains 3-D printed parts from MCC that are beautifully printed. The 3-D parts include new speed brake buckets and exterior brake panels, cockpit parts with a new seat, tires and wheels, missiles with launchers and bombs. A sheet of masks is also included in the kit. Several of the parts on the sprues aren’t used in the build and are clearly marked on the parts list. Special Hobby produces a few other Super Mystere kits so there’s a level of commonality between kits. I would recommend familiarizing yourself with the instructions before beginning construction. There are options with the aircraft, and utilizing the 3-D printed parts should be considered up front. The injected molded spues are well molded and contain crisp details. Panel lines are rendered in finely recessed lines. The basic shape of the completed model look correct to pictures I found on line.

The build took a bit more time than I had originally planned. Two major hurricanes came rampaging through my area (West Coast of Florida) about ten days apart unexpectedly altering my schedule and that meant I wouldn’t be able to complete the project in the recommended timeframe. My thanks to John Noack and IPMS for giving me extra time to take care of storm related damage and recovery, then complete the review!!

I wanted to incorporate as many of the 3-D printed parts that were included in the model as possible. This was the first opportunity I’ve had to incorporate 3-D printed parts into a model, and I was excited to try this new technology. The printed parts contain excellent detail and needed to be removed from their carriers. A razor saw took care of the larger structures, while an exacto took care of the smaller attachment points. The instructions were very clear where exact placement was needed. I cut (Yikes!!) the necessary sections of both right and left fuselage sections and installed and faired in the new buckets with super glue. The rest of the printed parts were relieved of their frames and a small amount of clean up was necessary before everything was ready to go.

Most of the rest of assembly was straight forward. One oddity I noticed was the fuselage was molded in three sections. In addition to the previously mentioned left and right sides, there is also a bottom piece that needs to capture all the interior subsections. This is where I ran into the most challenging part of the build. I took my time installing the bottom section to the completed left and right fuselage sides. I took over three days of aligning then applying liquid cement, then clamping and letting it dry. This is where the third set of hands would have been useful!! I completed the mating then sanded and puttied the resulting seams. There are several complex curves that need to be set correctly to make the fuselage work, but the slow speed I used for this step really paid off later when everything lined up well. This was the only place that needed extensive work. A few other smaller seams benefited from a little putty and quick smoothing. One other problem I encountered is there is no mention of needing to add weight to the nose to prevent tail-dragging. When the model was finished and the underwing stored added the balance point was a little too far back and some weight should have been added. However, there is little place in the forward fuselage to put it. I solved the problem at the end of the build by fabricating a smallish oak base and epoxied the model to it. This solution also solved the issue of the two pitot tubes extend from under the front air intake. They’re very prone to breaking off, which I did a few times during construction. While none of the issues I encountered were huge I was able to work past them. The rest of the model went together well, and the completed model looks good.

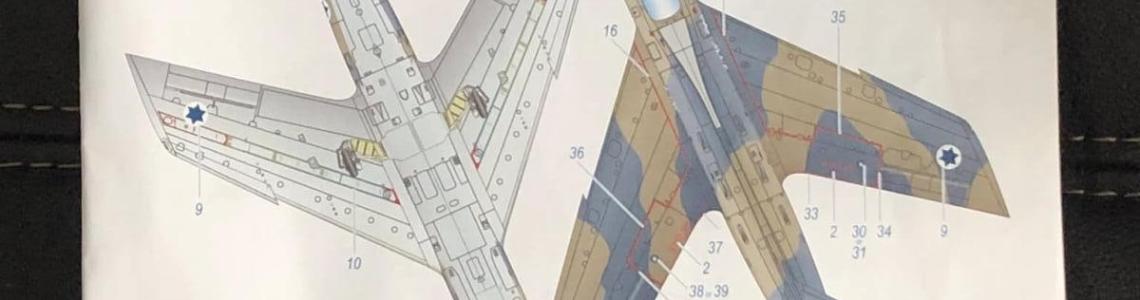

The instructions call for three paint schemes, two of which are in the standard IDF scheme of light green, tan and brown over a gray underside. This is usually the way IDF aircraft are painted. The third scheme is tan and blue gray over gray. I chose to do this one because I had the colors in my stash and didn’t need to buy and paint to complete the model. I also liked this one as it’s not a scheme normally seen. The model was painted with enamels and weathered with some artist oils and pastels. The blue gray was applied freehand over the tan base. The decals add a bit of color and went on very well. A bit of Micro set and Micro Sol made the decals easy to apply, and a semi-gloss clear coat over them made them disappear into the finish.

Final assembly was accomplished with no issues. Ordinance options with the kit and 3-D printed parts give a number of loads that can be added. I chose the missiles (Sidewinders?), small fuel tanks and napalm canisters and related rails and pylons. I used epoxy for the seeker heads, formation lights on the upper wings and landing lights forward of the nose wheel well. These added a sheen difference that really stand out against the semi-gloss finish of the model. The 3-D printed tires and wheels are very nice and a big improvement over the kit parts, and the completed speed brakes look great open. I’m glad I used them!!

All in all the kit went together well. Extra time was needed to install the bottom of the fuselage, but a slow pace and slow setting glue seemed to be the way to proceed, and I think the result was worth the extra effort. The 3-D printed parts are beautifully rendered and are a joy to work with. They fit the model well and the extra detail included makes them a welcome addition to the kit. Another option included is the canopy can be installed either open or closed. I chose the closed option, but the detail within the cockpit is nicely molded and would also look good in the pen position. The 3-D printed seat is very well done and enhances the interior greatly. I enjoyed this build a lot. It was challenging enough to keep my interest, but easy enough that I didn’t need to spend aa bunch of time fixing issues. The addition of the 3-D printed parts made for excellent detail and value to be added to the kit. The finished model looks good and scales correctly to other 1/48 scale aircraft and was a welcome addition to my model case. I highly recommend this kit to anyone interested in Israeli aircraft or would like to build a kit of something a bit different. To see all the offerings made by Special Hobby, check out their web site.

My thanks to Special Hobby and IPMS/USA for allowing me the opportunity to build and review this kit. And to John Noack for allowing me extra time to get the kit finished.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews