M7 Priest Early Production

History

Shortly after the beginning of World War II, it became apparent to US Army planners that there was a dire need for an armored, self-propelled artillery vehicle to support the troops involved in armored operations. Until something more viable could be developed, the army used the M3 half-track with an M2 105mm howitzer mounted in the crew compartment. This vehicle was designated as the T-19. However, this quickly proved inadequate and needed to be replaced, preferably by a fully tracked, armored vehicle able to offer better crew protection. Using the chassis from an M3 medium tank, two pilot models designated T32 were built and tested. Upon successful completion of the tests, the T32 was accepted for service in February 1942 as the M7 HMC (Howitzer Motor Carriage) with production starting in April 1942. The main armament was the M2 105mm howitzer, along with the M2 .50 cal. machine gun for AA and personal defense. The M7 HMC had stowage for 69 rounds of ammunition with 36 rounds being in the ready service bins mounted on the floor on either side of the fighting compartment. Ninety M7’s were shipped to the British 8th army in Africa. They were the first to use the M7 in combat during the second battle of El Alamein. The M7 was successful and was well-liked by the crews. A total of 3,490 M7’s were built and were used in combat by all allied armies, with several soldering on in smaller armies until the 1960’s.

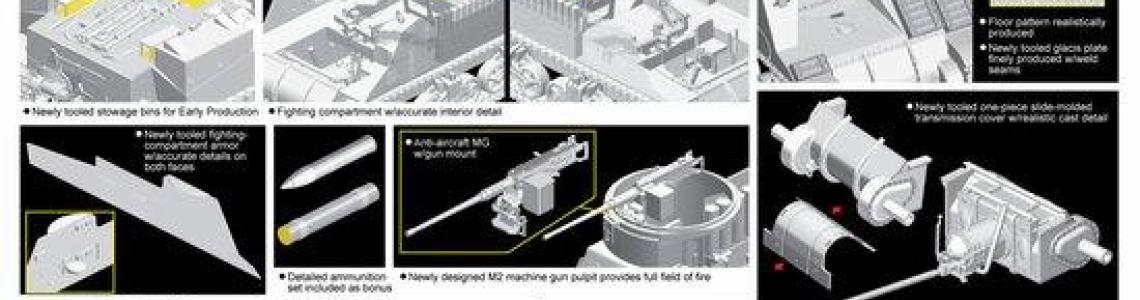

The Kit

This new Dragon release follows their first release of the M7 Priest mid-production (# 6637) and incorporates all the necessary changes to backdate the model to depict an early production version of the M7. This “Smart Kit” release has 302 parts (297 in styrene), 4 etched brass parts, and one turned aluminum barrel with nice, delicate rifling. The kit includes two lengths of DS100 track molded in soft styrene that can be glued using styrene cement. The track pattern for this release is the T41 which had the flat reversible track pads. The T41 are accurate and detail is depicted nicely; however, the use of T41 tracks on the M7 was short-lived and a set of T51 tracks would have been more useful. The early Priest used the early VVSS M3 suspension and this is depicted nicely. The road wheels are the open welded type with 5 spokes. All the suspension parts have fine casting detail but do not have part numbers or foundry marks present. Unlike earlier Sherman releases, the axle spindles for the idler wheels are not adjustable. This will not allow you to manipulate the axle to insure proper track tension unless it’s modified. To insure proper track tension, I cut one link off before gluing the track run together. This helps give the correct track tension without having to modify the idler axle spindle. This is also easily accomplished with the glueable DS track. The instructions are typical DML – well drawn, but at times busy. There are also a couple of numbering mistakes, which will be pointed out later. Due to the low parts count (low for DML), the assembly is accomplished in just 12 steps. Also typical for DML instructions is the ever-present painting instructions with only a few colors being indicated. Also, step 8 calls for decals (yellow stripes) to be applied to the ammo tubes. However, unlike the first mid-production release by Dragon, this kit does not include the stripes. I didn’t mind that too much as it saved me the time of placing 25 decal stripes on all the ammo tubes in the bins. Not an easy task at all.

Construction

As is typical, construction starts with the bogie assemblies. These were of the early M3 type and are well represented. The casting texture is fine; however, there are no casting numbers present on the bogie housing. The kit has 5 spoked, welded wheels while the idler has the correct 6 spokes. The drive sprocket is the flat machined type. The transmission cover is assembled in step two. This is a new three-piece transmission cover that has the casting numbers as well as the drain plugs present. The interior transmission and driver’s controls are added to the final drive housing, and this whole assembly is then placed aside until added to the hull later in construction.

The rear armored bulkhead (part A1) is assembled next. Dragon took a short cut here. Not only are the engine access doors molded closed, but the grab handle on the door itself is molded as a solid strip. This looks nothing like the actual handle. I cut mine off and made a proper handle from wire. The exhausts are well represented but the connection to the bulkhead is a little fragile. I managed to break mine off a couple of times before getting the bulkhead secured in the hull. The interior rear bulkhead (part A7) is next. The armored cover (part A8) needs to have a PE grille added. The spot where the grille is placed is molded solid. This is a bit unusual, as there are two open vents next to the grilled vent. These were molded open, but the area where the grill goes is solid. Actually it’s a non-issue as nothing is visible beneath the grille anyway. Dragon did, however; used the same molding technique with the vents on top of the engine deck. I chose to leave off the aiming stakes (part D36) that are mounted to the armor plate until later in the construction.

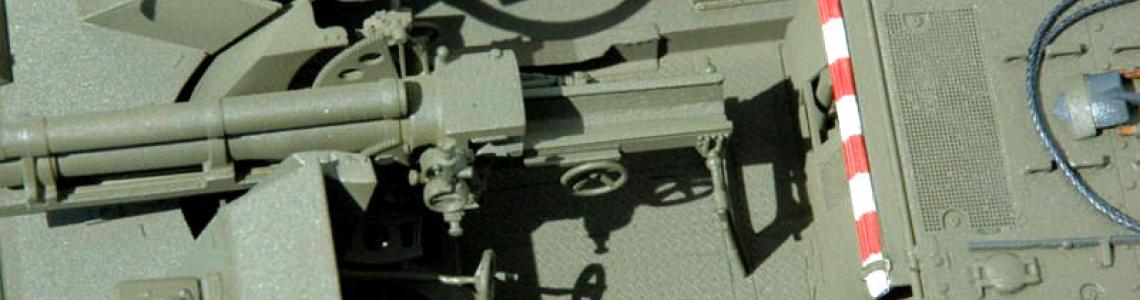

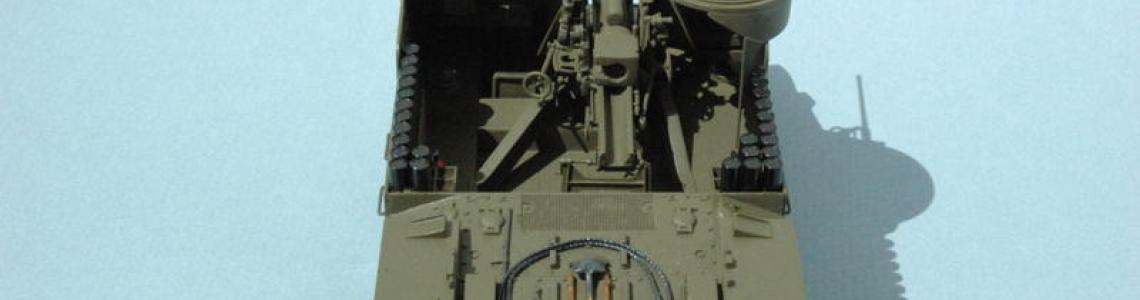

Construction moves on to the 105mm howitzer. The main part of the gun, which includes the recuperator, recoil cylinder, and gun tube are slide molded as one piece. This is nice, as it eliminates cleanup of the seam, which would be difficult. The end of the gun barrel is turned aluminum and has fine rifling on the inner surface. The instructions indicate that the travel lock pin on parts A13 and A43 need to be trimmed. I followed the instructions and trimmed them off as indicated. This proved to be erroneous, as when the actual travel lock was added in step 8 it did not engage with the gun carriage. I ended up having to shim the pins I cut off to get them to fit properly. I suggest using the travel lock (part C4) as a guide when trimming the pins on the carriage. Adding the gun shields was a bit difficult. The instructions were not very clear in this step. Start by gluing the bottoms (parts C25 & C26) to their respective shields. The bottoms have notches molded into them. Test fit to the bottom of the gun carriage. There are corresponding notches on the bottom of the gun carriage that the shield bottoms fit into. Test fitting is the only way to determine exactly where they fit. Start by gluing the right brace (part C8). Before the glue sets on the brace, glue the shield (part C28). Then manipulate the shield until it engages the brace. The top of the brace is notched to fit the top of the shield. Align it as best as possible before the glue sets completely. Now add the left brace the same way. Brace first, then shield. Glue part C18 between the two shields. Now, while still curing, look down the length of the barrel from the muzzle and align the shields until they are squared up. Actually, it’s not as hard as it sounds – just take your time and everything should line up.

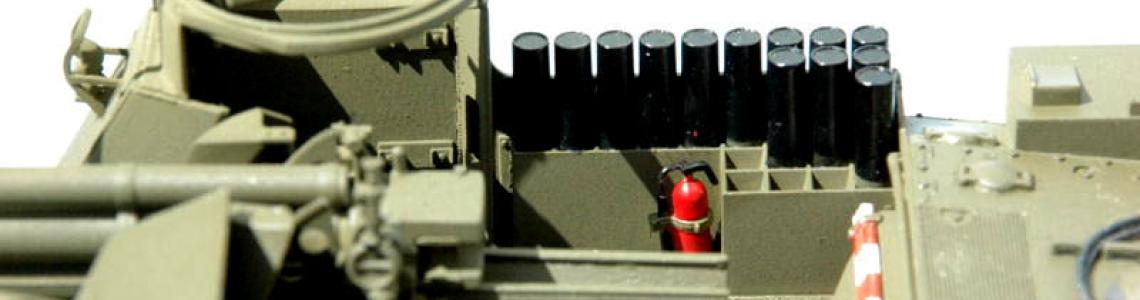

Once the howitzer is completed, assembly moves back to the interior of the vehicle. There are a few errors in the instructions at this step. Parts numbers C14 and C15 are reversed. This becomes obvious when trying to put them into the floor (part C17). Even the drawing is wrong. The uprights should bend outward and not towards each other as indicated. The ammo bins have several 105mm rounds in shipping tubes molded in place. They look all right but I would have preferred to have the bins molded empty, as in the old Italeri kit. As stated earlier, the instructions show the decal stripes being added to the shipping tubes; however, there are no decal stripes included in the kit. Also parts B37 and B38, as well as B33 and B34, are reversed. Unlike previous Sherman-based kits, parts B33 and B34 are fixed in place and not adjustable. This makes getting the proper track tension a little more difficult. In previous Sherman-based kits, this part was adjustable. This can be made to be adjustable with some trimming but I chose to shorten the length of track to get the proper track tension.

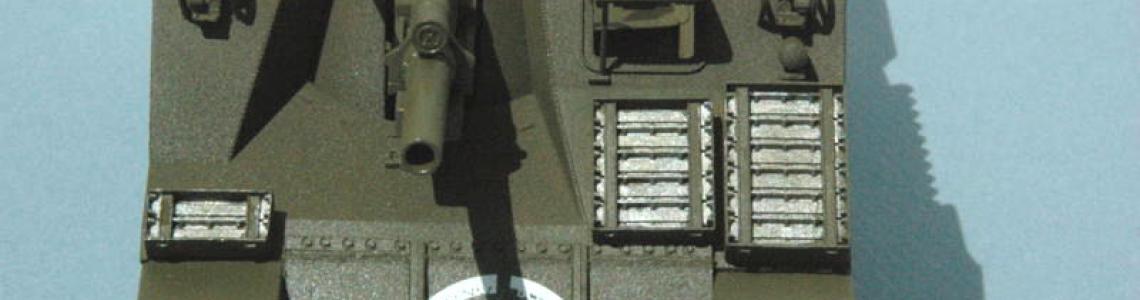

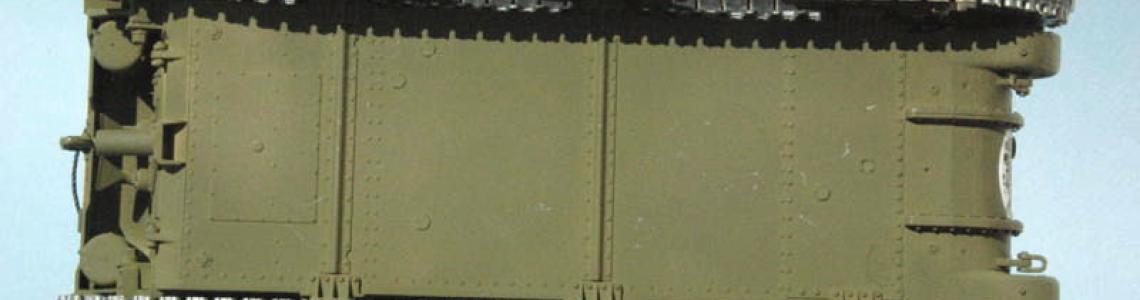

The riveted hull has all the drain plugs and inspection plates present and is the correct hull without an escape hatch. It has the 8 vertical hex bolt heads down each side as well as the 20 bolts across the bottom of the hull. The inside of the hull has slots to mount the interior floor, and there is also a drive shaft that runs from the bulkhead to the rear of the transmission. The driver’s area is well represented and the instrument panel is the long rectangular one instead of the square one seen in later versions. Unfortunately, there were no instrument faces included in the decal sheet, which would have been a nice touch as they are visible when viewed. There are no crew weapons included, but the weapon brackets are molded into the side walls. The side armor plates are new moldings with the short machine gun pulpit. Use care in cleaning these up. At first viewing, what I thought was flash was actually fine weld beads that fit nicely to the front glacis plate when the superstructure is assembled. The fit of the side walls and the front glacis was very nice, and the ammo bin brackets molded on the inside wall fit to the ammo bins extremely well, helping to align everything.

The rear engine deck has the extra vents properly located; however; they are not open but rather molded solid. The two side vents have an armored cover, so not being open is not an issue. However, the main engine vent located at the front center of the deck is also closed. This really is not a major issue as little is visible below the grille anyway. Just to be safe, I painted the recesses flat black before adding the grilles. The only other issue I had with the rear engine deck was with the tow cables. The molded eyes on the ends seem grossly undersized when compared to other Sherman-based tow cables. They can’t be replaced easily because the locking brackets are molded to the ends of the eyes. I also had a major problem with the tow cable supplied in the kit. The wire cable was very springy. I heat treated it a couple times and still could not get it to be less springy and coil properly. Also, the wire supplied was the same diameter as the end of the eye, making it impossible to drill out to accept the springy wire. After a few tries I tossed it and ended up using some line I have for rigging. Using rigging line was much easier and a lot less frustrating. The fit of the engine deck to the superstructure went without problems and everything seemed to fit very well, with construction going quickly and without problems. I finally added the track. To improve the fit, I cut one link off the end on each side. The track glued together without any problems and the fit was fine after the one link was removed.

The kit includes the usual water-slide decals printed by Cartograf. All markings have crisp edges and were perfectly registered. There are six marking options included: three unidentified US Army units,. one ETO unit in 1943, one Stateside unit in 1942, and one unit from Anzio, 1943. There are two British A Squadron Priests from Egypt in 1942, and finally a Free French Priest attached to the 2nd Armored Division in 1944. I chose the unit from the ETO in 1943. The white stars have a disruptive OD covering, which comes as an extra decal to add over the white stars. I was curious to see how this worked, and it went well and I was happy with the final results. My vehicle was painted overall OD. I gloss coated it and got the decals mounted. At this point I had to stop because of time constraints and needing to finish this review. I shot the pictures of the gloss coated model to complete the review. I do intend to weather the Priest as soon as my professional life stops interfering with my modeling life.

All in all, this was a fun build. There are some shortcuts taken by Dragon but, for the most part, the kit engineering was excellent. I was a little concerned at first with a multiple-part superstructure and just how difficult it would be to keep everything lined up, but my concerns proved to be unfounded. Everything went together quickly and cleanly and I am happy with the final result. I can safely recommend this kit to anyone having a few builds under his belt.

Special thanks to Dragon/USA for the review sample and IPMS for letting me build and write this review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews