Saab SK 37E Stör-Viggen

The Saab 37 Viggen was an aircraft ahead of its time. Its designers used an unorthodox construction which enabled the plane to meet all requirements which had been laid on it and in some parameters even surpass them. The Swedish Air Force ordered several various versions of the Viggen jet fighter, its basic design formed a universal platform which, using specialized equipment, enabled the plane to be used for different roles. The first prototype machine took off for its maiden flight on 8 February 1967 with E. Dalström at the controls. The aircraft was powered by a Volvo RM8 turbofan, a license-built variant of the Pratt & Whitney JT8D with an afterburner and thrust reverser which, in addition to the double-delta wing design, enhanced the plane’s performance the takeoffs and landings on short airstrips. The avionics of the Viggen was state-of-the-art at the time, the Viggen was the first type to be equipped with a computer with integrated circuits. The first version of the Viggen to see service with the Flygvapnet was the AJ 37 strike fighter followed consequently by the SK 37 two-seat trainer, the SF 37 reconnaissance version with cameras in a redesigned nose section and the anti-shipping SH 37 with much differing avionics, capable of carrying a range of anti-shipping weapons. Ten years after the first Viggen entered service, the second generation of the Viggen, the JA 37 arose that although it looked similar, was essentially a new design.

The dedicated trainer version, the SK 37 prototype, achieved its first flight on July 2, 1970. Subsequently, seventeen additional airframes were built. Ten of these airframes were converted to the SK 37E Stör-Viggen (Jammer Thunderbolt) electronic warfare variant, which is the subject of this kit. The SK 37E ended up being the last Viggen in service, finally retiring in 2007. I am guessing that the original SK 37 trainer variant can also be built from this kit. The major differences would be in the dorsal blade antenna, the decals and external stores. I am sure there were some slight differences in the rear cockpit as well, but in any case, the rear cockpit was set up so it could be easily switched between the training role and the jamming role. The SK 37E Stör-Viggens were planned to be re-painted in the two-tone air-defense gray scheme, but due to a lack of funding, only one airframe was re-painted (the box top subject). The Swedish Historic Flight is currently flying an AJS 37 Viggen (SE-DXN) and a SK 37E Stör-Viggen (SE-DXO)

This is the sixth 1/48 kit released in the Tarangus – Special Hobby collaboration of the Saab Viggen series. The initial release was the Saab JA 37 Viggen (TA4803) released in 2014 by Tarangus. This was followed in 2015 with the Saab AJ 37 Viggen (SH48148) from Special Hobby. 2017 Saw the release of the Special Hobby AJS 37 Viggen (SH 48188) followed by the limited production (500 kits) Saab SH/SF 37 Viggen (TA4807) from Tarangus. Special Hobby released an updated version of the AJ 37 Viggen (SH48148) that addressed early complaints with the canards and also included photo-etch for the cockpit. This kit is the latest release for the Electronic Warfare Aggressor two-seat variant, the Saab SK 37E Stor-Viggen (SH48150).

When Special Hobby first announced the SK 37E in 2015, there were some concerns voiced over the initial test-build. I really have to commend, Special Hobby for correcting and addressing many of the issues that I saw brought up on the internet. Issues that Special Hobby has corrected are largely included on “Sprue M” which appears may be available separately at Hannants and Rebell Hobby AB. “Sprue M” corrects the following issues:

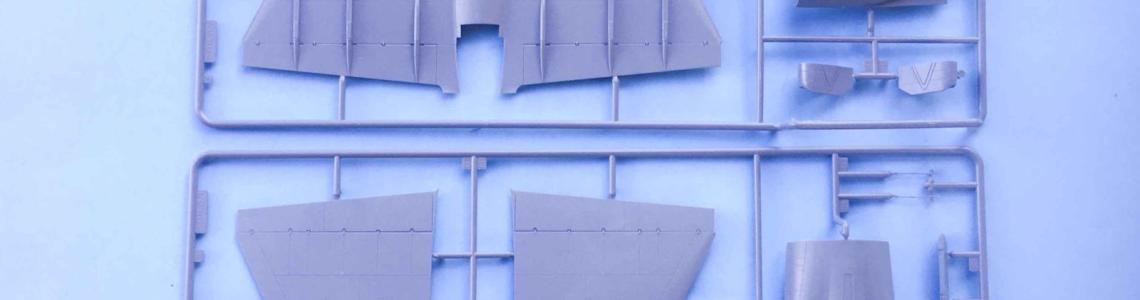

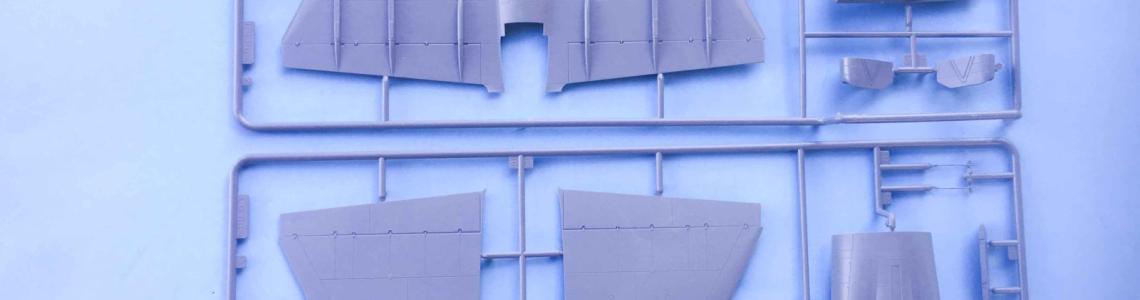

- Incorrect canards in the initial release of the AJ 37 Viggen are now replaced with canards (Parts M4 and M18) that have the correct flaps (Parts M2 and M3). This is essential since while on the ground the canard flaps are drooped at a 30-degree angle. I would also note that a pair of Czech Master resin canards and flaps are included in my kit, however, the newly injected canards fit perfectly, while the resin ones will require modifications to fit to the SK 37E fuselage as the canard mounting pins don’t align with the fuselage holes.

- Additional supporting braces that connect the fuselage and the intakes. The original kit only included the upper pair (Parts G141 and G142); now we have both upper and lower braces (Parts M13 and M14).

- The center pylon extension (Part M1) [the environmental conditioning system scoop] that also mounts the central drop tank now extends back to the ventral fin. The SK 37 ventral fin is also included (M12) that is shared with the JA 37 variant.

- A new vertical tail fin and rudder (Parts 5 and 19) replace the original one-piece vertical tail surfaces.

- The Auxiliary Power Unit (APU) is open once the landing gear struts hit the ground. You get to cut out the door opening, but everything else is there (Parts M20, M22, M15, M16, and M17).

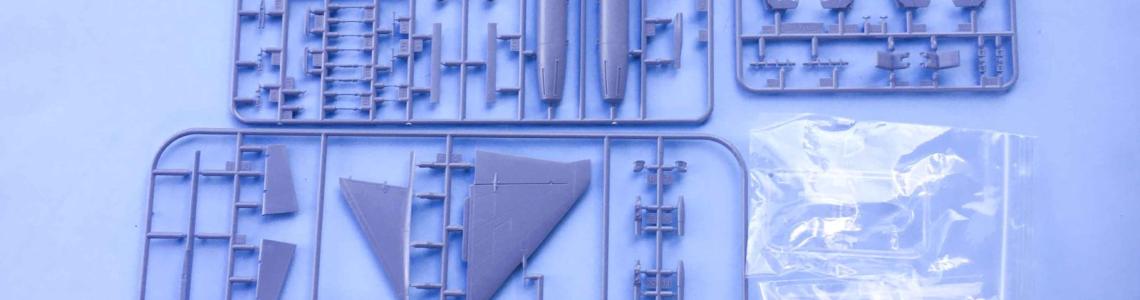

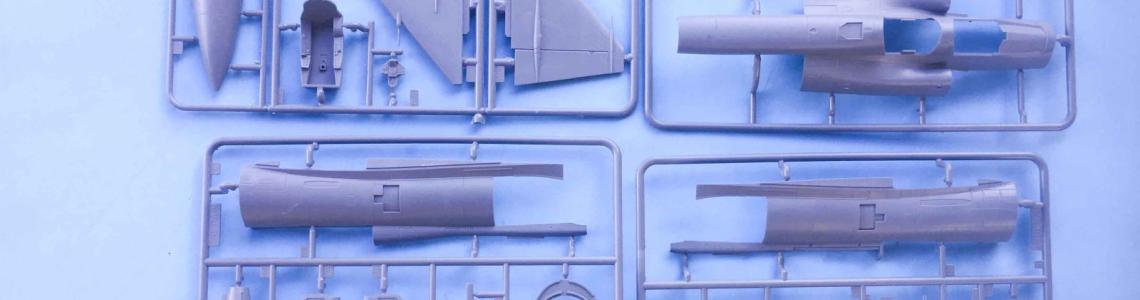

“Sprue M” also includes parts specific to the SK 37E, the twin rear cockpit periscopes, the twin ventral intakes, and a dorsal transponder antenna. This kit contains a total of eleven injected sprues, a sheet of photo-etch, and decals (including stencils) for three airframes and six camouflage schemes. If you are into aftermarket support, there are plenty available from decals, resin, photoetch, masks, pilots (seated and standing), brass pitot and AoA, and metal landing gear. Indeed, the Special Hobby instructions provide photos for aftermarket resin for the Ejection Seat, Thrust Reverser, Air Brakes, Wheels, and the m/70 Rocket Pod. I consider the Master Models brass parts essential to the look of the Viggen. Where the nose and vertical tail probes are at the limit of injection molding, this brass set gets both the nose and vertical tail probes to the correct size and additionally provides the tiny AoA probe on the right side of the nose (the kit provides the AoA probe as photo-etch). The kit seat is good for an injected kit, with each seat composed of 5 injected parts and 12 photo-etched parts. The Czech Master resin seat (Q48 219) is a step up from that provided with the kit. If you plan on going with the Pilot Replicas or Neomega resin seats, be aware that they are taller and wider and you will need to modify your cockpit depth and width. I would also note that the CMK Wheelset (48 221) is a significant improvement on the main wheels. The injected plastic main wheels supplied in the kit appear oversize in diameter and undersize in width. The CMK thrust reverser petals (Q48 222) add more detail as does the CMK Air Brakes set (Q48 220). The m/70 Rocket Pod set (4310) add an option that is not included in the standard injected plastic. I would also offer up for consideration the Scale Aircraft Conversion metal landing gear to make sure the injected plastic gear does not break later on due to the weight of the kit (I managed to break the main gear during painting).

The marking options include:

- SK 37E, s/n 37807, Code F4-70, splinter, 2004

- SK 37E, s/n 37809, Code FC-09, splinter, 2005-2007

- SK 37E, s/n 37811, Code F21-74, grey on grey, March 2000

- SK 37E, s/n 37811, Code F21-73, grey on grey, April 2003

- SK 37E, s/n 37811, Code F21-73, grey on grey, April 2004 with replacement dorsal panel in splinter camouflage

- SK 37E, s/n 37811, Code F21-73, grey on grey, April 2005 ELITE exercise with red thunderbolt tail marking

This Special Hobby kit is packaged in a standard separate lid – bottom box with a nice painting of the only SK 37E to be painted in the two-tone grey air superiority camouflage. The instructions provide a parts map, which is a big assistance to locate parts on the sprues. Paint colors are called out for Gunze paints in the instructions along with color profiles for the camouflage schemes and to point out stencil placement. All of the grey injected sprues were packaged in a large plastic bag. The injected clear parts were packaged in a separate bag. The decals and the cockpit color photo-etched parts are bagged together.

Construction

I taped the kit together to see if there were any major issues, and all the major components fit together quite well. I started out in the cockpit, assembling both ejection seats. Since you have a left and right ejection seat, you end up with a big seam vertically between the two seat halves. The seat cushion will hide most of the seam, but you still have the headrest to take care of. Milliput putty took care of that. After the basic assembly of the injected parts, the photo-etched parts are up next. I had no real problems with the seat harnesses, but I did have fun with the ejection seat arming lever. On the Viggen ejection seat, the arming lever is a swinging bar that comes out of the right side headrest frame. When armed, it folds into the gap between the headrest and the top of the ejection seat. When not armed, this lever sticks out more or less straight-out from the ejection seat. You get four photoetched parts, plus you get to create part of the ejection handle from a plastic rod of your own choosing. The arming lever also has a declining diameter from where it is mounted to the handle and appears to have a slight curve to it. I have not been able to get the photoetch to behave properly yet, but I will continue to work on it.

While working through the ejection seats, I also hit the tandem cockpits. Utilizing the photo-etch, you cut away all the nice detail on the cockpit side panels and the main instrument panels. It appears that the rear instrument panel before scraping and adding the photoetch is your standard SK 37 Viggen trainer, so I suspect another kit is on the way for the normal trainer version. If not, the rear instrument panel in injected plastic is ready to go. I was able to assemble the tandem cockpits with no drama and soon had everything glued into the cockpit with the exception of the ejection seats (I rarely glue the ejection seats in until the very end, if at all, on most models). In any case, the completed kit ejection seats are a very tight fit. I assembled the Heads-Up-Display, using the photo-etch (PE39) and a rectangular clear film (supplied by the modeler. The windscreen was glued down and the two canopies secured with Future before masking the clear transparencies.

Steps 14 and 15 get into some drilling and slicing. The lower fuselage (Part D102) requires some careful drilling to be able to mount the ventral twin scoops. Get out your micrometer and measure precisely to the dimensions in the instructions to drill four 1mm (~ #60 Carbide Drill Bit) holes. This where you also cut out the panel opening for the RAT. I used the same #60 Carbide Drill bit and drilled holes inside of the panel lines for the RAT cover, and then used a combination of a #11 scalpel and file to get the entire panel opening to its proper shape. I skipped to Step 17 to get the main intakes assembled and spent quite a bit of time trying to get rid of the intake seams. Finally, I was able to attach Part E133, which is an intake alignment spacer, and then added the painted front fan facing (Part E126). Next, it was test fit, test fit, test fit to make sure the intake assembly, the lower fuselage, and the upper fuselage mated properly. I had to sand the RAT housing a bit to fit properly, but in the end, everything fit nice and snug. I skipped Step 19 for the installation of the thrust reversal petals, as I was able to see that I could easily attach them at the end of the build. I pre-painted the exhaust interior and then assembled the exhaust sections.

I was concerned about how the front fuselage was going to mate well with the rear fuselage. I skipped to Step 23 to add the main wheel boxes to the lower wing and glued the upper wings near the wing tips. My rationale for this was to improve the mating of the front and rear fuselage fit, using the wing assembly to assist in alignment. One problem to be aware of: On Part E107, there is what looks like a raised panel, followed by a cutout section on both sides. I was not able to find any documentation of this other than there is a panel there, but the entire surface should be smooth. Out came the Milliput to fill in the cutout section and the sanding paper to remove the raised panel.

Steps 25 and 26 involve attaching the nose and intake lips to the main airframe. I had no issues with the nose cone and thought I was fine on the intake lips. I was a bit surprised coming back after gluing the intake lips on to find that the panel line gap was larger than I wanted. You may want to be careful here. I suspect that the intake assembly may have put pressure on the intake lips. Next time I will spend more time on this fit. The vertical fin and rudder are two parts. I used Lego blocks to assure proper alignment. I skipped Steps 28 through 30 (landing gear assembly) to continue adding airframe parts. This includes the ventral fin, the canards, the lower intake scoops, and the drop tank. The main gear doors can be displayed down, but all references show them closed (up) when on the ground. The instructions show that the tabs for the main landing gear being down should be cut off. The “M” sprue canards fit very well, better than the resin canards included. The rear canard elevator should be angled down at a 30-degree angle when the plane is at rest. I also added the intake bracing at this time. Keep in mind they are handed and there are two at the top and (from Sprue “M”) two at the bottom.

Next up was adding the upper fuselage airbrakes and a variety of scoops. Parts 151 and 152 are very small cooling scoops attached on the tail fairing. You will want to be very careful here as they can easily be knocked off. Parts 127 and 128 are small triangular parts that will need to fit between the fuselage and wings. Here is where I finished fitting the inside of the wing assembly to the fuselage to assure a good fit. The rear cockpit periscopes, the RAT assembly, and the dorsal antenna were also added. I had no issues except for the air scoops 145 and 146. I feel their bases should have been sanded down more to achieve a better fit.

Now that the bulk of the airframe was assembled, I went back and addressed the nose gear assembly. The main strut, torque link, and the retraction link appear to be a very strong assembly. The nose gear well lights (one on each side) were added next. I used a masking agent to cover the front lenses and painted the rear of the lights in silver. Adding the nose gear doors and their retraction arms were next. I would caution here as I found the nose gear doors extremely susceptible to handling so I may try to add the gear doors after painting next time. The main gear for the Viggen is rather complex so take your time on their assembly. I had great trepidations on having all the gear touching the ground at the same time, but this turned out to be a non-issue. The tandem axle is supported with several braces that help align the tandem axle. Where I wished I had a third hand was attaching the gear doors to the main gear assembly. This was tricky, but in the end, I had no issues in the alignment of the gear door retraction arms with the main landing gear. I saved both the nose and the main gear wheels until after all painting and decaling were completed to minimize the risk of them going out of alignment during handling.

The airframe was primed with Tamiya Semi-Gloss Black followed by Gunze C324 (upper surfaces) and Gunze C308 (ventral surfaces). All other detail painting was done with Vallejo Air. I prepared the airframe for decaling by spraying several coats of Future and set it aside for several days to cure properly. The specific airframe and national markings were added next, followed by the plethora of stencils. The decals performed quite well with no breakage and all appeared to be in register.

After painting, I secured the remaining transparencies using Future. This includes a ventral and dorsal light (Part 911) that I painted in Vallejo Transparent Red. The wing transparencies (Parts 907 and 908) were painted Vallejo Transparent Red and Transparent Green. These parts are tiny and sharp! I managed to draw blood while I was getting them to fit properly. The rear clear transparencies (even smaller) were added with Future. Finally, I inserted the ejection seats and set the two canopies on. Please note that I have not glued the canopies down, but they do fit quite well.

Overall Evaluation

Although I created a few problems on my own, I was very pleased with the build of this kit. I was very pleased that Special Hobby spent the extra effort by making many of the changes from the standard AJ 37 kits. I’ve already noted that they made many corrections after unveiling a ‘test model’, and I highly commend Special Hobby for that. I am also quite pleased with the other parts available on Sprue “M” as these parts significantly support building a more accurate Viggen. This model took me longer to build than I had expected it to, but my real-world job interfered a bit more than normal. I am elated at having the ability to build an accurate SK 37E Viggen and will be building a few more. Highly Recommended!

My thanks to Special Hobby and IPMS/USA for the chance to review this great kit.

Highly Recommended

Comments

Saab 37.

Where are the photos of the build?

Clare

Images

They were added to the review incorrectly - I will try to have them up soon.

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews