Aerobonus is part of Aires and produces a line of items meant not to enhance the actual airplane model but to add to a diorama or vignette. This can include figures or simple diorama accessories. This set is a WWII USMC pilot in 1/32nd scale describing his exploits in a nice action pose. The set is in four parts, the body, the head and two arms. All parts are cast well in Aires traditional gray resin with nice crisp details. Take care removing the parts and assembly will be a snap. I added the arms to the body and in hindsight, I should have left them off. I did keep the head separate and mounted all the parts to toothpicks for ease of painting.

Welcome to IPMS/USA Reviews

Introduction: The primary organization of the IPMS/USA Review website is by IPMS/USA National Contest Class. Within each Class there are sub-menus by kits, decals, books, etc. The Miscellaneous Class is for items that are not class specific or that cross two or more classes.

IPMS/USA Members: We encourage you to submit reviews, both here and to the Journal. To volunteer for membership in the IPMS/USA "Reviewers Corps" and submit your own reviews, please read the Guidelines For Submitting Product Reviews.

Manufacturers, publishers, and other industry members: IPMS/USA is pleased to offer your company the opportunity for product reviews. All product reviews are performed by IPMS/USA members, and are posted in the publicly-accessible section of our website. With very few exceptions, we perform full build reviews of new kit releases, aftermarket products, and supplies. If you would care to provide product samples for review, please contact John Noack, IPMS/USA 1st VP.

To learn more about IPMS/USA, please see our About Us page.

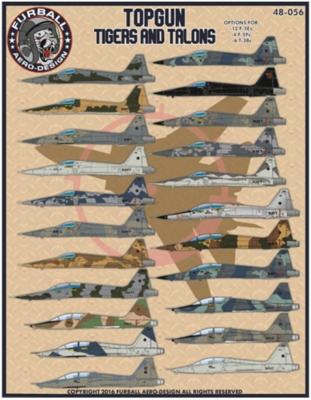

The movie Top Gun, love it or hate it, raised a lot of interest in the Navy Fighter Weapons School, and that interest was not lost on modelers with the markings of the Adversary planes standing out. Furball has given us an enormous sheet of markings covering twenty-two different schemes covering both the F-5E, F-5F and the T-38A between 1976 and 1986. There are options for twelve F-5Es, four F-5Fs, and six T-38s. As noted in the header, there are separate sheets for the 1/48th and 1/72nd scale planes and both cover the same subject. AND, there are complete markings for all 22 planes!

Here’s a complete rundown of the aircraft that are included in this set:

This Eduard set is for F-4 Phantom seats which need gray seat belts. There is also a set for green belts. The photoetched fret is colored and has 22 pieces on thin metal. All of the seat belts are gray in color with top straps being olive drab. All buckles are bare metal give a great color to the set. There is also a nice set of instructions for installing the belts.

Many people don’t know that I am half English. I use that as an excuse to love some of the more interesting British aircraft. One such plane is the famous Avro Vulcan. Just something about that big bat shaped wing appeals to me. I have never had the good fortune to see one fly in person but I have seen video and have been able to view a few in the flesh.

This, of course, means that I have the old Airfix 1/72nd scale kit in the stash. To say that this kit needs some loving attention to build right is probably an understatement based on some of the builds I have seen online but one day I will tackle her and mark her up in as one of the bombers used in the Falklands.

One thing you may not know is that the Vulcan fleet had had their refueling probes removed prior to 1982 and the maintenance crews had a hard time tracking down probes to get aircraft ready for action even resorting to taking probes off museum planes.

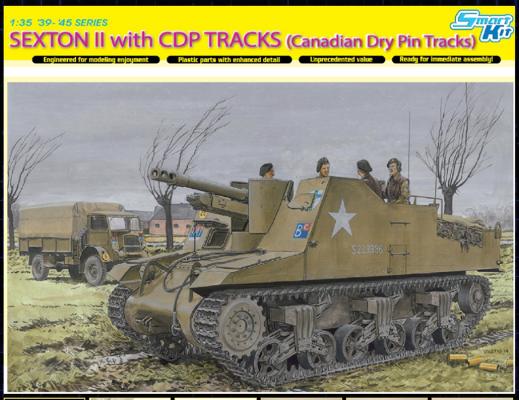

First off, I’d like to apologize to Dragon USA and IPMS for the extended delay in getting this kit review completed. My sincerest apologies go out to both.

The Sexton II was a British SPG, based on the Grizzly tank hull and carrying the 25 pounder artillery gun. It was produced in Canada by Montreal Locomotive Works from 1943-1945.

The Kit and Construction

The Dragon kit is a very nicely detailed replica of this SPG, with many small extras that lend greatly to the end product. One very nice features of this kit is that there are many, many extra parts leftover once the Sexton II itself is completed. These would be great for the diorama builder or to throw on this and other vehicles.