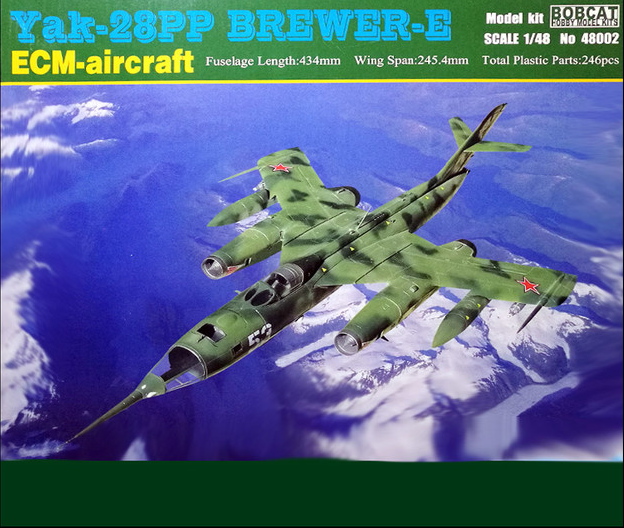

Yak-28PP Brewer

Brief History

The Yakovlev Yak-28 is a swept wing, turbojet-powered combat aircraft used by the Soviet Union. Produced initially as a tactical bomber, it was also manufactured in reconnaissance, electronic warfare, interception, and trainer versions, known by the NATO reporting names Brewer, Firebar, and Maestro respectively. Based on the Yak-129 prototype first flown on 5 March 1958, it began to enter service in 1960.

The Yak-28 was first seen by the West at the Tushino air show in 1961. Western analysts initially believed it to be a fighter rather than an attack aircraft—and a continuation of the Yak-25M --and it was designated "Flashlight". After its actual role was realized, the Yak-28 bomber series was redesignated "Brewer".

The Yak-28 had a large mid-mounted wing, swept at 45 degrees. The tailplane set halfway up the vertical fin (with cutouts to allow rudder movement). Slats were fitted on the leading edges and slotted flaps were mounted on the trailing edges of the wings. The two Tumansky R-11 turbojet engines, initially with 57 kN (12,795 lbs) thrust each, were mounted in pods, similar to the previous Yak-25. The wing-mounted engines and bicycle-type main landing gear (supplemented by outrigger wheels in fairings near the wingtips) were widely spaced, allowing most of the fuselage to be used for fuel and equipment. It was primarily subsonic, although Mach 1 could be exceeded at high altitude.

Yak-28PP reporting name "Brewer-E". Deployed in 1970, it is notable as the first Soviet electronic countermeasures (ECM) aircraft. It was unarmed, with an extensive electronic warfare (EW) suite in the bomb bay and various aerials and dielectric panels for transmitting the jamming signals. Excess heat generated by the jamming equipment was dissipated by heat exchangers under the centre fuselage; it did not include a radome. Produced in the 1970s in unknown numbers.

Total production of all Yak-28s was 1,180 aircraft.

The Kit

What's in the box? There are six sprues molded in a medium grey plastic, plus one sprue of clear parts. All sprue were individually bagged. I did find a few loose parts in two of the bags. There are several small parts that will require care in removal and clean up. The panel lines appear to be a bit deep, but after an application of primer, paint and gloss coats should be fine. There is no PE included.

A decal sheet is included with markings for several natural metal and camouflaged Russian and Ukranian Air Force aircraft.

Instructions

There are eighteen pages of instructions, with each page being a three-part fold-out panel printed on both sides. There are well over 40 steps to the construction with individual parts and paint colors noted. Page 3 lists the paints and colors required, with painted based on Mr. Hobby, Tamiya (both acrylic and aerosol cans) and Model Master. There are several vertical cut-away details in the instructions that assist in the alignment of various sub-assemblies. This was helpful.

Spend some time reviewing the assembly sequence before cutting any parts free from the runners. It appeared that a good deal of painting various components will be required before closing up certain subassemblies (i.e. cockpit, wheel wells, engine nacelles, etc.).

Construction

Cockpit

The cockpit consists of a tub, bottom panel, an instrument panels, and various small parts.

The ejection seats are assembled from five parts and the end result is a bit clunky. I replaced them with the Aires KM-1 resin seat that comes with PE seat harnesses.

Fuselage

The fuselage is comprised to a nose section for the EW officer that is in two halves, the main fuselage that is made from the side halves plus a full-length bottom panel, and finally a tail cone. Fuselage assembly is shown in steps 6 through 10 for the nose section, a step on page 6 that was not numbered, and step 34 on page 12. This is where the review of the instructions is so important.

I departed from the instructions by first gluing the right nose section half (part I2) to the right side of the fuselage (part H1), and did the same with the left side Part I3 and H6). Fitting two circular sections or assemblies together as shown in the instructions always seems to run the risk of a step at the join. I did a test fit these parts together before applying and solvent and things appeared OK.

The front portion of the crew area involves the installation of several small parts (radios and electronic gear). Several raised ejector pin parts make their presence known and must be removed. In addition, the open joints between parts I3 and H6, and I2 and H1 will need to be addressed.

Once the wheel wells and cockpit subassemblies were in place it was time to join the fuselage halves together. There was a bit of adjusting and finessing to get the halves to mate properly, and with a progressive application of solvent, supplemented by taping and clamping the first part of the fuselage was assembled. Next, the belly pan, part I4, was fitted and glued in place. Care is required to get the longitudinal join surfaces to be flush with each other. More tape, more clamps. Next, the dorsal spline, part H22 is glued in place. There were alignment tabs on the top side of the fuselage to assist with the placement. Lastly the tail subassembly with fitted and glued in place. This will be a large model!

Once the fuselage and tail assembly had cured a small amount of filler was used along various joins. I used Vallejo acrylic putty to fill the fine gaps wiping the excess off with a damp cloth. One issue was the join between the dorsal spline and tail: there was about a 1/16' wide gap between the parts that required filling and sanding.

Note: the "odd rods" located on the top surface in front of the cockpit were molded as part of the fuselage were replaced with short lengths of brass rod for a more durable detail. The nose section with its long probe was not fixed in place until the model was ready for priming and painting.

Landing Gear

The two main gear wells are built from several parts to create the open bottom "boxes". The instructions would have the gear installed at that time. I felt that with planning and lots of luck I could install the gear after everything was assembled and painted. No point in risking breaking those parts.

The two outriggers may be fitted closed or deployed. I chose to deploy them for this build. Each involves four parts and are a bit challenging to assemble. These assembled were painted off the model and installed once all painting, decals, and weathering was completed.

Engine Nacelles

Each nacelle is assembled from two halves plus miscellaneous scoops and two pressure relief doors. There are two-part shock cones that fit into the intake plus an inlet ring. The exhaust portion has a two-part barrel chamber, plus a blade section, a flow straightener, and a nozzle. I decided to assemble the nacelles halves without the intake shock cones or exhaust nozzle components in place. The pressure relief doors have optional parts for a closed or open configuration. The instructions do not clearly indicate which parts are to be used for either configuration The exhaust chamber barrel was assembled and fitted in place and the nacelle halves glued together. The joins needed to be filled and sanded for a smooth surface.

The two-part shock cones needed some filler and sanding to eliminate a step at the join.

Fitting the nacelles to the underside of the wings was a bit of a challenge. Progressive gluing and clamping is the order of the day.

Wings

The wings are constructed from a top panel plus two underside panels. Some trimming of the mating surfaces was required to allow the panels to fit flush especially near the wing tips. The two, large wing tip probes would not be installed until near the end of the assembly process, but before priming and painting. When it came time to install the two probes I found the fit to be a problem. The mount portion of the probe fits into a rectangular recess on the top side of the wing. Neither would seat properly and some trimming and sanding of the probes' mounting surfaces were required. The right side probe was especially difficult to fit in place. Much trimming, sanding and test fitting was necessary before a less-than-perfect fit was achieved. A small amount of filler was required to minimize gaps.

When it came time to fit the two underwing fuel tanks in place I realized I had forgotten to drill holes for the mounts. Fortunately fitting and gluing the tanks in place was not difficult with the resultant alignment quite acceptable.

The completed wings are fitted to a contoured mating surface on the fuselage sides and held in place with a substantial tab fitted to a slot in each wing. Tamiya thin cement was run along the join top and bottom with care taken to assure a proper alignment.

Tail Assembly

The tail assembly is made from two halves plus a poseable rudder. It took a bit of trimming and sanding to get the rudder to fit properly. The tail assembly is fitted to the top of the fuselage and is aligned with several raised tabs for a proper location. Everything was aligned visually before the solvent hardened.

Miscellaneous Stuff and the Weapons--Two RATO pods are included and are to be mounted on the sides of the aft fuselage section. Each pod is assembled from three parts. The rocket nozzle did require drilling out to open the outlet. I painted the RATO with Tamiya Burnt Iron and dry-brushed the high lights with silver. The nozzles were painted stainless steel.

The only "weapons" included are two rocket pods which are actually chaff dispensers. The pods were painted Alclad aluminum.

Clear Parts

The clear parts are without distortion and are crisply molded. The pilot canopy is separate from the windscreen and may be posed open or closed. The hatch for the ECM crew member may also be posed open or closed.

Painting

The clears parts were masked and the various openings were closed off to seal out the primer and paint. The model was primed with Tamiya fine white primer and allowed to cure for 24 hours. I was careful during the painting process to avoid damaging the wing and nose probes.

I had decided to paint "White 53" from the Soviet Air Force based at Monino. This aircraft has nine camouflage colors on the upper surfaces. The plans and profiles on page 17 of the instructions appear in conflict with each other on the colors describing them at various shades of green and brown. The color chart on page 3 did not help a great deal. The plans and profiles were also confusing as to the various color locations. I was somewhat on my own. The undersides were painted first and allowed to cure for 48 hours. After the cure time, I applied a thin coat of Future to protect the underside from the masking process. This too was allowed to cure for 48 hours. The undersides were then masked with Tamiya masking tape and small pieces of tissue to cover the larger surfaces.

The camouflage colors were applied freehand. I used Tamiya paints thinned with 93% isopropyl alcohol for this model. The surface was sealed with three coats of Future in preparation for the kit decals.

Decals

The decals were individually cut out and dipped in warm water. Within seconds they were ready to be laced on the model. I used several decal solvents to get the decals to conform the surface recesses and raised details but found some of the decals to be a bit resistant to these efforts. Once the decals were in place and dried I applied an AK Interactive panel line wash. Everything was then sealed with a coat of Model Master clear flat.

All the loose parts were then fixed in place to complete the model. It is big, it is sleek, it is done!

Note: upon taking the images for this review I noticed the rear dual landing gear wheels were above the table surface by about 1/16". It appears the outriggers are a bit too long. Need to be tweaked.

Conclusion

The kit parts and instructions reflect the somewhat complex nature of the build, but during the process, I had no significant problems. Everything went together as required. The instructions do become a bit busy near the end of the assembly where many of the smaller parts and subassemblies come together. One needs to review all of the instructions before beginning the assembly and carefully plan out the painting process. The end result is a very nice model of a very sleek jet aircraft.

I wish to thank Lucky Model and IPMS USA for the opportunity to build and review this kit. I recommend this kit for the Russian aircraft enthusiast, but it is not for the beginner. This was an enjoyable project and I am pleased with the results.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews