USS Enterprise NCC 1701 Refit

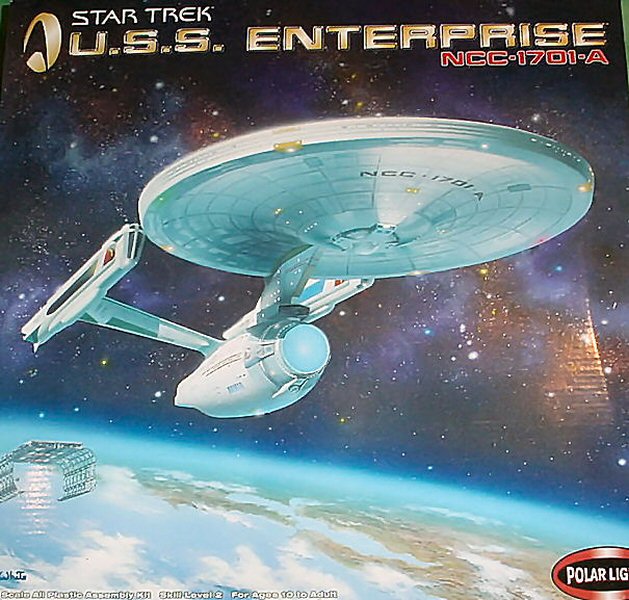

The first thing that you will notice, even before opening the box, is that this is a big model! The box measured at about 17 inches on each side and is five inches deep, weighing in about just less than five pounds. Opening the box one of the things that draws the eye is the saucer. The saucer, which is about 16.5 inches in diameter, weighs in at just less than 2 pounds. For the math challenged among us, that equates to a saucer circumference of just less than 52 inches. As a reference, a standard NBA basketball hoop has a diameter of 18 inches. Each engine pod is about 17 inches long. The model will take up an estimated vertical displacement of about 10 inches. Okay, it's big. It's heavy.

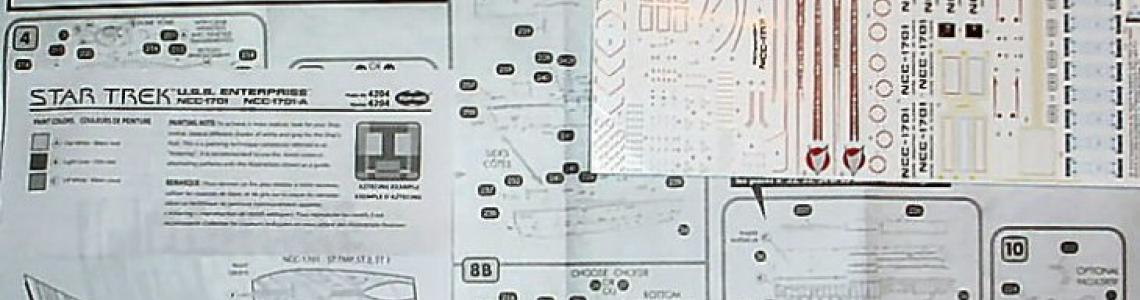

The instructions are printed on a "poster" sized sheet of paper, folded into a 5.5x 8.5 packet. I will tell you right away that I do not care for the instructions. There are numbered areas showing which parts need to be assembled, and each area is linked by arrows into a sequence of assembly. This design didn't work for me. I really struggled with the proper sequence of construction and finally had to actually pay attention to the instructions in order to figure it out. Assembly is shown on one side of the "poster" and the painting and decal instructions are shown on the other.

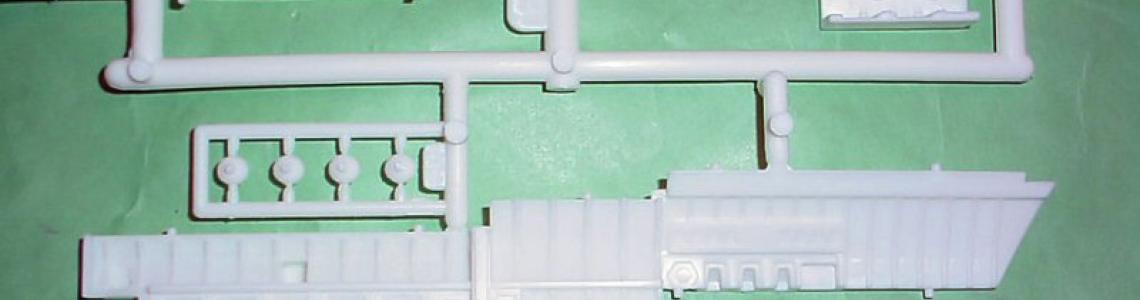

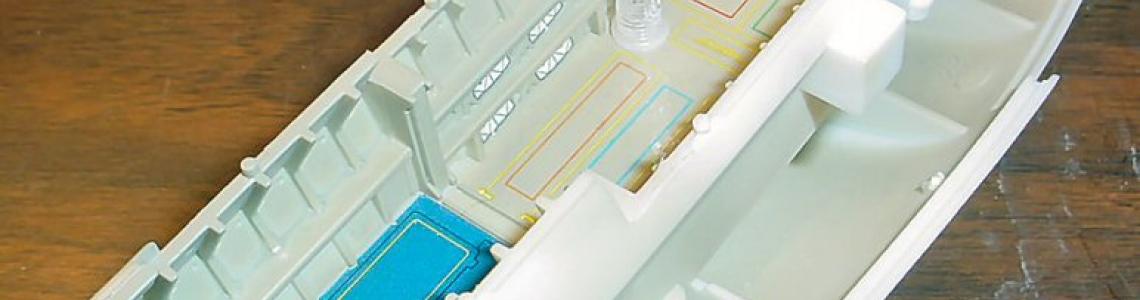

Like most models, other than ships, this one is built "inside-out". This means that you will begin this model by building the shuttle bay. The shuttle bay fits into the secondary hull and the secondary hull bottom, top, and sides are then assembled around the shuttle bay. You will quickly realize that this kit is well designed and engineered. The parts fit together very well and have large locating pins and biscuits that allow a virtual snap fit for most parts. Dry fitting all subassemblies is highly recommended. You will find that even though it's not shown on the kit instructions there is a sequence in which the various parts should be assembled. Once you've dry fitted the subassemblies it will be a simple matter to disassemble everything and repeat the construction process, this time using glue.

I will tell you that this kit cries out for a lighting kit. I will not be installing any lighting, though. This model is a commission model being built for a non-modeler, and a decision was made to hold down the cost of construction by not installing any lighting. An internet search found a source for some really nice looking after market parts and electronics (see references at the end of the article).

Step 8A is a key step in the construction process. In this step you will assemble the secondary hull and attach the engine pod pylons to that hull. If you've ever built one of the old AMT USS Enterprise kit then you already know that the attachment points between the pylons and hull were a weak point and subject to breakage. The Polar Lights folks got it right. The pylon halves snap together with a very tight fit and require only a very small amount of sanding to hide the seams. The pylons then snap onto a set of pegs molded on the upper secondary hull piece. The design of these pegs and the flange on the pylons which snap over the pegs is well thought out and well molded. The pylons will actually stay in place without glue.Following the placement of the pylons on the upper secondary hull piece, the right and left sides of the secondary hull are attached. These pieces also snap into place using another set of molded pegs and, when in place, add additional reinforcement for the pylons. I really am impressed with Polar Lights and how they engineered this aspect of this kit.

Once the pylons and sides of the secondary hull have been attached it will become apparent that there will be a substantial seam between the sidewalls of the secondary hull and the top piece of the secondary hull. A rather wide gap between these hull components on either side of the pylon attachment point will need to be closed. This area, if you are an aircraft builder, could be labeled as the "leading edge of the wing root". I believe that if I had worked the parts more carefully I could have reduced that gap, but not made it disappear completely. In the end I decided that I would rather fill the gap before attempting to realign the parts by snapping and unsnapping the pylons repeatedly in an attempt to diminish the gap.

Now things speed up quite a bit. The engine nacelles, once assembled and puttied up (there is a noticeable seam along the joint between the right and left halves) snap onto the pylons with a pin and hole system. On each of the pylons three pins slip into holes in the nacelles and guarantee practically perfect alignment. The attachment point is about 4 inches in length and about 1/4" wide so there is plenty of surface area along the point of contact between these subassemblies. You can test fit these subassemblies to check for alignment and strength and then separate the parts, if need be, in order to do any last minute clean up prior to permanently attaching the engine nacelles in place. While the pin and hole arrangement can hold the engine nacelles in place without glue it is recommended that they be glued into place.

You have probably already finished the paint job by the time your reach this stage of assembly and you've realized that it is easier to paint the subassemblies prior to final assembly than it would be to wait to paint the model when it is fully assembled. And you will probably consider adding some of the decals at this stage as well. I found that adding decals was a simple task after final assembly, with the model mounted on the display stand.

The saucer is a huge piece and one will find that its components fit fairly well. The top and bottom saucer halves snap together and eight curved pieces form the exterior wall between the upper and lower saucer halves. These curved pieces will need to be glued into place with care. They are supposed to snap into place, and to some extent they do, but it is important to get a good, tight seal on the upper and lower edges of these pieces where they touch the saucer parts.

The saucer is attached to the hull with a two piece assembly called the neck. It is a credit to the kit designers that once attached to the neck, one can lift and manipulate the saucer by simply holding the neck. The neck snaps into the upper hull and is held in place by six pins molded onto the neck.

Other than the attachment of a few smaller pieces the assembly of the model is done at this point. While quite large, the model is strong and sturdy and can be handled with ease without to much concern about bits and pieces falling off.

Markings are included for two versions of the Enterprise, and there are a large number of very small markings on the decal sheet. The decals adhere well to the surface of the model, but some care will need to be exercised to avoid trapping air underneath the decal. The decals feature excellent register and are thick enough to prevent "see through" even over the Aztec paint scheme.

There is a great deal of surface area on this model and the painting process will consume a great deal of paint. In order to not only speed the process of assembly but to also cut down on painting expenses I primed the model with a rattle can of gloss white purchased from Wal Mart for 98 cents per can. I used Gloss White #20000. A great aid in the painting process were the Aztec Masks by Gator's Mask used to produce the Aztec pattern on the saucer.

Lastly, the base for the model uses a 3 point attachment system to support the model. Two clear plastic rods run from the base to locating holes in the underside of the saucer. The third point of attachment is a clear piece of plastic that uses a biscuit and slot to hold the hull in place. These three points of attachment function without being glued into the Enterprise but it is recommended that all three pieces be glued into the base.

Polar Lights is to be congratulated for producing such a well engineered kit. The design is clever and helpful in regard to alignment and strength of assembly. The decals are not up to the standard set by the kit molding and design. While the decals are strong and accept some handling without breakage, and while the decal sheet is full of very small and well registered markings, the decals are printed on a backing material that tends to silver profusely when applied. The instructions are a bit confusing in regard to the assembly process and require more attention than called for when building the average kit. This model is stunningly big and its physical size is both a positive and negative. On the positive side there is plenty of room inside the model for extra details to be added and for lighting equipment. On the negative side it will consume a large portion of one's model display space when completed. This kit is recommended for all skill levels from the rank beginner to the expert.

References, After-Market, and Things

- IPMS USA Journal, May/June 2008, Volume 20, Number 03, Simon Mercs' Superdetailed Starship

- ColorPlace interior/exterior Fast Dry Spray Paint #20000 Gloss White

- After market electronic parts are available. Go to http://www.monstersinmotion.com/cart/sci-fi-as-in-science-fiction-item-… for $300+

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews