T-45 Goshawk

With the release several years ago of the Italeri and Airfix quarter-scale BAE Hawk kits, many of us U.S naval aviation fans wondered if we would finally see a mainstream kit of the T-45 Goshawk. Following on their other notable naval air kits, Kinetic Model Kits now offers this very detailed rendition of the Navy’s newest intermediate/advanced jet trainer.

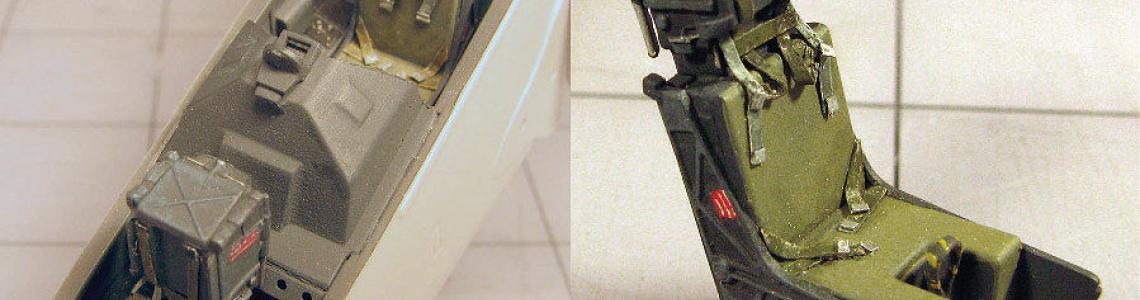

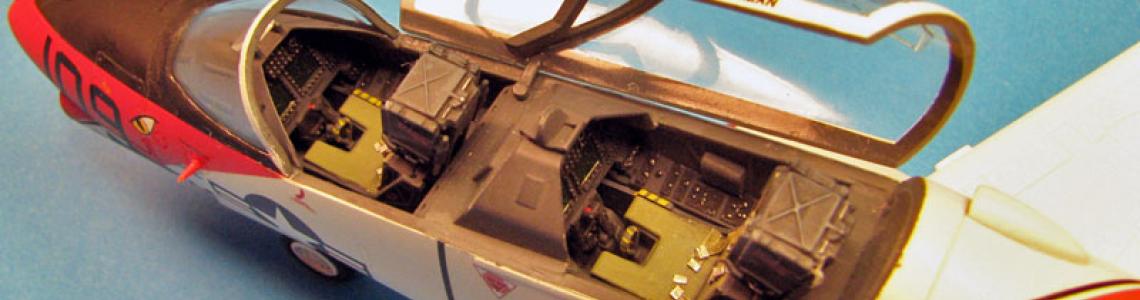

The kit offers the option of either the T-45A or T-45C, the primary differences being in the cockpit, with the earlier A model equipped with traditional steam gauges, and the C model equipped with glass instrument panels. Both of these options are well represented with raised detail panels. The overall two-seat cockpit is nicely detailed with main and side consoles and highly detailed ejection seats. With the addition of tape seat belts and buckles, I found them a close match to some of the best resin seats. I thought it curious that the kit provides no foot pedals (which I made from scratch and added), until I had the cockpit assembled and realized that you could hardly see them anyway. One important deviation: the instructions would have you add the instrument panel/dash hood assemblies after the pit is installed in the fuselage. Well, don’t wait to do that – they won’t fit there that way. Attach the hoods to one side of the fuselage and then put the halves together and save yourself a lot of frustration. The cockpit and front wheel well are all part of the same assembly, and it’s a very tight squeeze, taking up nearly the entire front fuselage. You’ll have limited space to fit whatever nose weight you can into those remaining vacant compartments. No matter how hard I tried, I couldn’t eliminate some slight gaps in the front fuselage joint, so these were filled and sanded smooth.

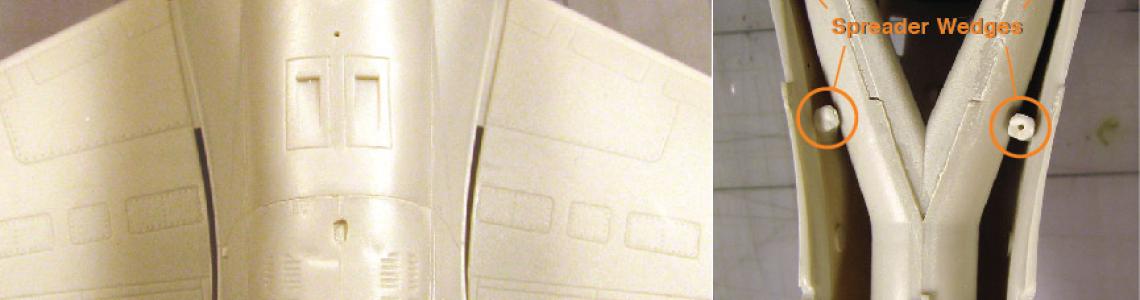

Once you start working on the wings, you come across some of the quirks of the kit’s design. The kit offers detailed main gear wells, but instead of being molded into the upper wing halves as is the usual practice, the wells’ narrow sidewalls must be separately assembled and attached to the inner wing. The fit of these parts was less than stellar, and there was a good amount of flash on them, so some very careful cleaning and trimming was required to insure a smooth, tight fit of the upper and lower wing halves. The attachment hole for the main gear is formed from the fitting together of the well walls, and unless you’re careful and make sure this opening is correctly placed and sized during this assembly process, it’ll lead to more frustrating problems later on (ask me how I know this).

When the time came to attach the wings to the fuselage, the gaps in the front fuselage seemed minor when compared to the ones at the wing-to-fuselage joint. Uncorrected, they amounted to almost 1/16th inch on either side, too much to fill with putty alone. These gaps also affected the connection of the intakes at the wing root. The simple solution would be a spacer bar placed between the fuselage wing joints – or so it seemed. Unfortunately in this case, there’s an internal intake/engine trunk that runs the length of the fuselage. That and the main wheel wells take up nearly all the space within the fuselage between the wings, leaving only enough room for a sliver of a spacer bar (but plenty of opportunity to break the trunking repeatedly while trying to fit the spacer!). Eventually, I dropped the spacer bar idea in favor of smaller spreaders placed between the inner fuselage and the intake trunks on either side, fore and aft. Spacers were also needed inside the wing roots to prevent a step at the upper wing-to-fuselage joint. After all that, there was still a substantial gap on the fuselage bottom at the aft end of the wing-to-fuselage joint (I had to choose between a gap at the front or a gap at the rear joint. A rear gap kept the already rough fit of the engine intakes from being even worse). I had no choice but to add a plastic strip plug this time. Now, the gaps at the intakes were small enough to be filled with putty.

Prior to painting, most of the remaining small parts were attached – horizontal stabilizers, antennas, wing fences, pitot, etc. The misnumbering of some of the small parts came into play at this point, requiring considerable back and forth between the model and the instructions to try and determine just what part was what, and just exactly where they were all supposed to go. Plenty of opportunity here for self-inflicted wounds by confusing small parts, and I didn’t miss many of them (the Carper Monster was a big help here, too). The canopy and windscreen were masked and sprayed first with the dark gray cockpit color, then a primer coat of white. My intention was to build this with a closed canopy, which would hide the few remaining open seams inside the cockpit. It was at this point that I discovered how poor the canopy fit was. There’s a substantial step between the fuselage and the front of the windscreen, which had to be smoothed with putty, and a very noticeable gap either between the canopy and rear fuselage, or between the canopy and the windscreen – take your pick. I also noticed that the canopy would not seat snugly down onto the fuselage. With the canopy masked, it was hard to tell why, but it felt like canopy was resting just slightly on the forward ejection seat. At this point, there was no easy fix to fit the canopy in place, so the hidden seams around the cockpit were filled with Magic Sculp and then painted (remarkable stuff, Magic Sculp. A two-part epoxy/resin that fills like soft putty and smoothes with water, then dries rock hard. No sanding needed, great for hard-to-get-to spots.).

Painting and decaling followed and was simple and straightforward. The cockpit, wheel wells (previously painted flat white then “dirtied up” with dark washes), and exhaust pipe were masked with my favorite masking medium, Silly Putty. An overall flat white base coat was followed by a custom-mixed hi-vis Trainer Red made from Testors small bottle red and about 10% Chrome Yellow. The intake edges were painted a red to match the decal intake warning markings, then everything was buffed and Futured. I used kit decals for most of the standard markings and stencils. Designed by TwoBobs and printed by Cartagraph, they’re excellent. One very nice touch is the star-and-bar and the “NAVY” decals that are cut and segmented to fit over the humps in the lower wing. It would have been impossible to fit the lettering or a standard national insignia decal over the protrusions with regular one-piece decals. Nevertheless, I used a bit of Solvaset to complete the conforming process here. The “Tiger” markings and numerals are from the Caracal sheet, and they, too, are excellent. A final Future gloss, and then a thin coat of Testors Dullcoat was applied to take the shine down a notch. Finally, the landing gear and associated doors were then attached. I had a set of Scale Aircraft Conversions metal gear for this kit, but I chose not to use them. Nice as they were, I didn’t feel that they offered any significant improvement over the very detailed and sturdy kit gear.

I’d have to give this kit a mixed grade. The overall detail is very good, with really nothing needed to add except some belts for the ejection seats. But the fit in some areas is fair to poor, like something I would have expected to see in a kit decades older, and the overly complicated design of some of the parts and assemblies left me wondering “what were they thinking?” more than once. Considering the very good reviews I’ve read on earlier Kinetic releases, I was surprised at the variable overall quality of this build. Obviously, nothing here was insurmountable, it just proves that, even in this latest “Golden Age” of modeling, you can still find a new kit that’ll throw you a curve. Thanks to Stevens International and IPMS for providing the Kinetic Goshawk for review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews