Ford A Gangster Car

The following excerpt is taken from ICM’s product website.

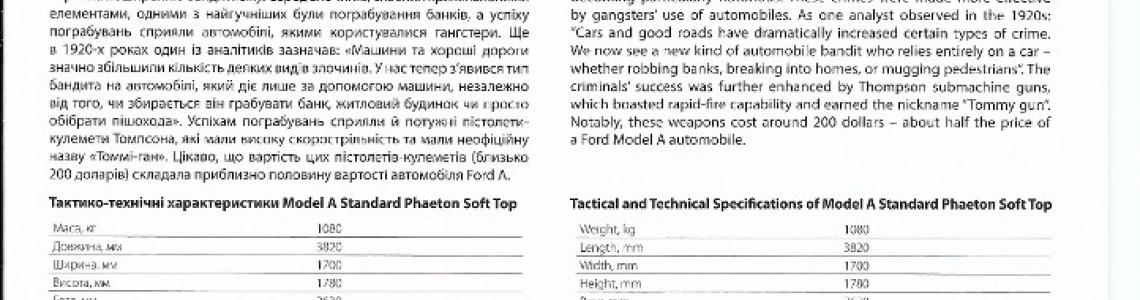

The unregulated growth and oversaturation of the United States [stock] market led to the Great Depression, beginning with the October 1929 stock market crash. This economic crisis fueled a rise in banditry, with bank robberies becoming particularly notorious. These crimes were made more effective by gangsters’ use of automobiles. As one analyst observed in the 1920s: “Cars and good roads have dramatically increased certain types of crime. We now see a new kind of automobile bandit who relies entirely on a car—whether robbing banks, breaking into homes, or mugging pedestrians.” The criminals’ success was further enhanced by Thompson submachine guns, which boasted rapid-fire capability, and earned the nickname “Tommy gun.” Notably, these weapons cost around 200 dollars – “about half the price of a Ford Model A automobile.”

History

The Ford Model A was Ford Motor Company’s second major success after the iconic Model T. Introduced on December 2, 1927, it succeeded the Model T following 18 years of continuous production. Designated as a 1928 model, the Model A was available in four standard factory colors and represented a notable advancement in styling, comfort, and performance.

Offered in a wide variety of body styles — including coupes, roadsters, convertibles, sedans, phaetons, wagons, and commercial vehicles, the Model A appealed to a broad range of buyers. It was the first Ford to adopt the now-standard driver control layout, featuring a conventional clutch, brake, throttle, and gearshift. It also introduced safety glass in the windshield and offered a rearview mirror as an option. Power came from a 201 cubic inch water-cooled L-head inline four-cylinder engine, delivering 40 horsepower.

Box and Contents

Measuring 12 inches x 9 inches x 2 1/2 inches, the box features a vibrant image of the model in front of a bank with machine guns lying against the car and the pistols with the money bag on the street. All sprues are molded in grey and packaged in a single large cellophane bag. Upon opening, I found no issues with ICM’s packaging approach. There are a total of 219 parts included in this particular kit.

ICM has incorporated sprues from its earlier 2024 release, Kit #24050, the Model A Standard Phaeton Soft Top, into this kit. Sprues A, B, C, D (two sprues), F, H, the clear sprue and tires were all included in the Model A. Sprues J and K (two sprues) are unique to this kit.

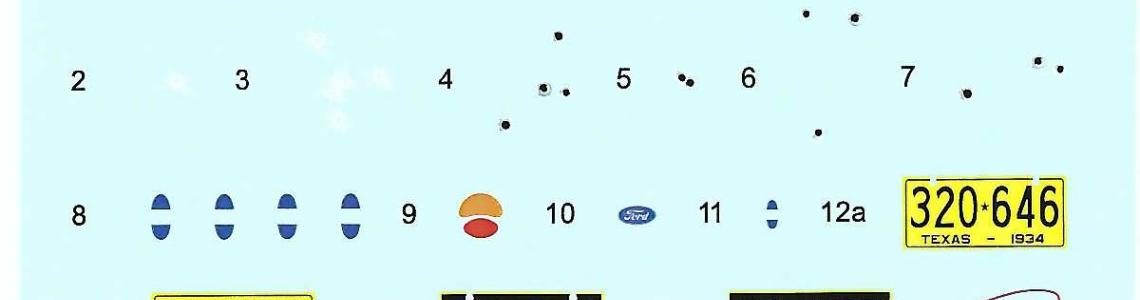

There is a twenty-page portrait-style instruction booklet covering the 89 assembly steps with color callouts for ICM paints. ICM includes window mask templates in the instruction booklet, located on page 19, for use on the front windshield. An ICM Acrylic Water-Based Paints 4-page reference booklet is included, as is a small decal sheet. No photo etch parts are included, and there are no chrome parts.

ICM organizes the construction into distinct sections: frame, engine, frame components and tires, and body. I would recommend watching ICM’s YouTube video featuring an excellent build of kit #24050, the Model A Standard Phaeton Soft Top in 3D.

Construction

Steps 1–4 involve attaching the front frame cross member, the double-channel central cross member, and linkages to the main chassis rails. In steps 3 and 4, the shock absorber bodies (parts D7) are attached to the frame. Finally, in step 4, the steering gear assembly (part F23) is installed. The details on the frame and parts are exceptional.

Steps 5 through 19 cover the assembly of the Ford inline four-cylinder engine and transmission. The left and right engine block halves are joined, along with the oil pan. Also, the transmission and clutch are assembled and then mounted to the engine. It is worth noting that ICM omitted the oil filler tube, which reference photos show positioned just behind the generator. Uncharacteristically for ICM, there was also a small amount of flash present on the intake manifold (part F28). The distributor and starter are well-detailed, and adding wiring could further enhance the engine’s appearance.

As modelers, we are all familiar with the “carpet monster” claiming a critical part and in this case, one of the spark plugs (part D1) made a miraculous leap off the table. To replace it, I used a small piece of wire with a diameter matching the original part to replicate the missing spark plug. The engine was first primed with Ammo by Mig One Shot Black Primer, followed by two coats of Vallejo Model Air 71.012, a close match to ICM 1069. Various details were then painted using Ammo and ICM colors, including ICM 1023 Aluminum, ICM 1002 Black, and other required shades. Weathering was done using pigments and washes.

As mentioned earlier, ICM has produced an excellent replica of the Ford Model A inline four-cylinder engine. Aside from the previously noted omissions, it provides an outstanding foundation for modelers to enhance with additional wiring and tubing for even greater realism.

Steps 20–24 begin the chassis assembly. During this stage, the front and rear axles are built up, along with the axle hubs, body supports, and both front and rear bumper braces. Various brake and steering linkages are also added to the frame. The instructions are vague in several areas, leaving some parts open to interpretation. Having solid reference material on hand makes placement far easier. Finally, the two-piece exhaust system is joined and installed.

The frame was first primed with Ammo One Shot Black Primer, followed by two coats of Vallejo Model Air Black (71.057). The engine was then test-fitted into its designated position on the frame. The fit was precise, with the mounting points aligning cleanly and requiring little adjustment.

Steps 35 and 36 focus on fitting the spoke wheels and rubber tires to the frame. The wheel detail is excellent, and the tires are installed easily. My only reservation is that ICM could have engineered a more secure attachment method, as the current setup does not provide much holding strength once glued in place. Once the frame was completed, the wheels were treated as a subassembly — first primed, then finished with Vallejo Model Color Lime Green (70.827).

Steps 37–60 focus on assembling the body. Several of these stages are straightforward, involving nothing more than joining two parts together. Step 37, however, instructs the builder to cut away sections of the step boards on the fenders (parts A8 and A9), with the cut areas highlighted in red. The instructions do not explain this modification, leaving its purpose unclear. I ultimately chose not to conduct this step.

Step 55 covers the assembly of the radiator, including the addition of a small radiator cap. I chose not to glue the completed radiator into the frame at this stage, as I planned to apply a chroming technique later in the build.

Steps 60–68 focus on installing the seats, attaching the left and right engine side panels, and fitting the one-piece hood. Additional grab handles are also added at this stage. Since I wanted to highlight the richly detailed engine that ICM provided, I cut the hood into two sections and reinforced them with photo-etch bracing so the hood could be displayed open. The seats were first primed with Ammo One Shot Black Primer, then one coat of Vallejo 70.871 Leather Brown. To achieve a satin finish, a light coat of Model Master Semi-Gloss 4637 was applied.

Steps 69–79 cover the installation of the steering wheel, windshield with rearview mirror, spare tire, front and rear bumpers, license plate holder with light, and the headlight bar with its assemblies. To take advantage of the chroming technique I planned to use, I left the bumpers and headlight bar off until after the vehicle was painted. Notably, in Step 71, ICM includes a masking template for the windshield — an excellent and very welcome addition to the instructions.

Steps 80–86 focus on constructing the foldable roof and attaching its ribs. ICM supplies the roof as a molded one-piece part, and the detail is impressively realistic. Care is needed with the roof ribs, as they are very thin and can easily break if mishandled. The roof itself was painted before installation, and all interior detail painting was completed in advance.

Steps 87–89 cover the assembly of two leather cash carriers along with two machine guns and two handguns. The luggage carriers are well-molded, capturing a convincing leather texture that responds nicely to washes and dry brushing. The small arms, while delicate, are crisply detailed for the scale and look especially effective once painted with metallic tones and are lightly weathered.

Painting

The body was primed with Ammo One Shot Black Primer, then airbrushed with two coats of Tamiya Lacquer Paint LP-1, thinned at a 2:1 ratio with Mr. Color Leveling Thinner (paint to thinner). The roof received a base coat of Ammo Black Primer, followed by two light coats of Ammo Rubber Black 033. Other assemblies were painted as described earlier in the construction, using a variety of paints from ICM, Vallejo, Ammo by Mig, and Tamiya.

For the chrome finish, I applied a technique adapted from gel nail products, which are easy to source and surprisingly effective. The process used a Super Glossy Mirror Effect White Moonlight Chrome Powder along with a Gel Topcoat for Chrome Powder. Parts selected for chroming were first primed with Vallejo Black Gloss 77.660, and once dry, a thin coat of Gel Topcoat was applied and cured under a UV light for 60 seconds. The chrome powder was then gently rubbed onto the surface with an eyeshadow applicator and buffed with the clean end to achieve a polished look. Additional buffing further enhanced the mirror effect. Any remaining powder was removed with a light puff of air, and the finish was sealed with another thin coat of Gel Topcoat, cured once again under UV light, effectively locking in the chrome effect.

Decals

ICM’s decals are top-notch, offering crisp print detail and a thin, flexible film that conforms effortlessly to surface textures. When applied with Micro Set and Micro Sol, they settle in smoothly and adhere cleanly, resulting in a hassle-free finishing process with no visible silvering.

References Used

- https://mafca.com/instructionbooks/

- https://www.scribd.com/document/380283716/ford-model-a-instruction-book-by-ford-motor-company

Conclusion

ICM offers an impressive kit at an affordable price. The level of detail is outstanding, and to showcase the impressive detail and functionality of this kit, I chose to present it with the hood open and sitting on a diorama concrete base. Modelers familiar with ICM kits will immediately recognize the exceptional craftsmanship and diligence. The molding quality was top-notch, with minimal flash requiring cleanup. I highly recommend this kit to anyone looking to add a well-executed and visually engaging piece to their collection. Thanks to ICM and the IPMS-USA for allowing me to review this kit.

Reviewer Bio

Phillip Cavender

Phil Cavender, IPMS/USA #50085, is a retired pharmacist from the Veterans Administration, having retired in 2011. While he explored model car building as a child, it wasn’t until 2015 that he rediscovered plastic scale modeling. His renewed interest emerged while researching his father’s military history, which led him to a local hobby shop. There, he met a former UK military tanker who reignited his passion for the hobby. After relocating to Myrtle Beach, Phil teamed up with six skilled modelers to co-found the Grand Strand Scale Modelers chapter of IPMS/USA. He now focuses on building armor models in scales from 1/35th to 1/16th.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews