Bristol Beaufort Mk. I, Bombing Raid, (Part 2)

ICM has released a new 1/48th scale Bristol Beaufort Mk. I, Bombing Raid version with decals devoted to No. 22 and No. 217 Squadron. For this boxing, there is an additional Sprue W (3X) that will turn this Mk. I into a bombing raid ordnance configuration versus the torpedo version of the previous boxings (there is no F2 or torpedo trailer sprue in this kit). This is PART 2 of this kit review and PART 1 can be located here:

In the Box

The box and contents review are in PART 1.

Review Process

For this build review, I decided on the Bristol Beaufort Mk. I, L9878 MW-R, No. 217 Squadron, Autumn 1941, as the final configuration. This is a box stock build but I did not follow the instruction build sequence since there are area of improvements noted below that may help the builder.

ICM has you started in the usual interior build up. This starts off with the areas aft of the cockpit in the bomb bay areas. Here, you will have to drill eight (8) new holes to attach the bomb racks (step 06). After that, bulkheads, wing close outs and spars are added, and instructions have you painting these areas interior green. Next up is the cockpit and the instrument panel is a decal. You will need a softening solution (Micro Sol, Solvaset, etc.) to help the decals sink into the recessed instrument bezels. The pilot’s seat belt is painted on. Once done, I enclosed both fuselage halves together and begin the process of filling seams.

The next step is to install the clear nose and canopy. However, this is where I deviated from the instructions and started the wing sections since I was waiting for the fuselage cement to cure. Prior to wing assembly, make sure to drill out the holes for the hard points that are outboard of the engines. By using the rack mount (part W28), holes can be easily “eyeballed” since it is close to panel lines as a reference point.

The engine assembly is a visually daunting task on paper. However, the parts assemble easily once you get into the order of sequence and a routine is established. The hardest part is removing the small exhaust tubes from the sprue frame. Note, painting sequence will need to be thought out prior to final assembly since brush access will be limited with all the exhaust tubes.

Wing engine cowling was next. The cowlings are a straightforward assembly, however, I did cut and trimmed away the upper tab on parts D38 & D39 since these need to be removed to allow the aft cowling flap ring to fit under the intake scoop. When trying to fit the assembled cowling over the engines I noticed there was a very tight fit due to some circular friction tabs inside the cowling. I removed these tabs which enabled me the opportunity to install the cowlings at the end since the engine exhaust ring glues to the interior of the cowling.

Painting the leading-edge ring of the cowling was a trial-and-error process to try and get the copper-brass color. I masked the ring and exhaust tube and used Tamiya Flat Copper (XF-6) as the base coat. Then I proceeded to mix acrylic black-brass and brushed on the paint. Not perfect but close enough after three tries.

When trying to install the propellers, the prop hub to engine shaft is a conical flare design. Not great for rotating props but will require cement to secure it to the engine shaft. I, however, wanted a more secure prop installation that had some rotation ability. The propeller has a hole located at its hub and I decided to install stretched sprue to match the diameter. I cemented the sprue to the engine’s shaft end and located the prop over the shaft and let dry (Note, the prop was not cemented to the sprue extension). Once the cement had cured, I cut the excess sprue to be even with the prop’s hub. This extension provided a tighter fit than the flare design (no cement needed to secure the prop) and allowed rotation.

After that, the landing gear is another visually intimidating assembly on paper due to the long thin fragile parts. But once you start, it assembles surprisingly easy and fits into the wheel well precisely. The hardest effort is removing parts from the sprue and not breaking any of the thin gear pieces.

Wings are then installed to the fuselage. Note, in the molding process, ICM designers have added a small “step” at some of the parts edges that are noticeable at the sharper trailing edges. This process adds more plastic to the thinner edges and helps to eliminate “short shot” parts. This is a very commendable process from the designers, but modelers will need to sand away this “step” for a smoother-realistic finish.

Control surfaces (horizontal stabilizers, ailerons, rudder, flaps) are separate assemblies and were installed later in the build sequence.

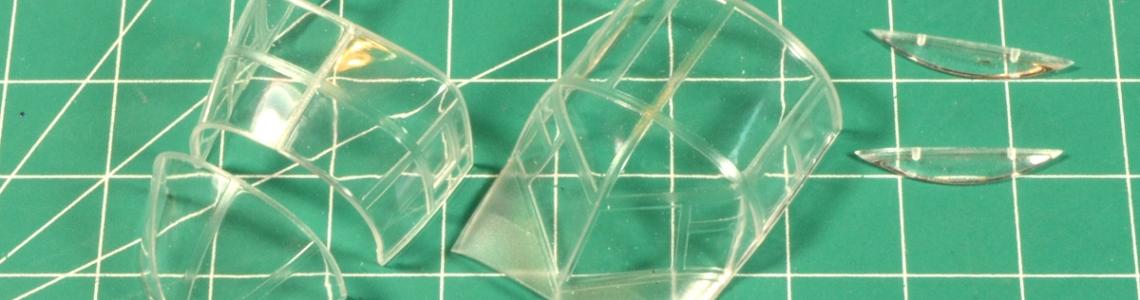

Back to the nose canopy. These parts are well molded and clear; however, they are in multiple pieces. The trick is being able to assemble them together and somehow fill the seam lines. Based on past builds with similar situations, I first coated the clear parts in Future. This will create a protective barrier during assembly since I will use Super Glue (CA) as the filler and the Future will prevent “crazing” on the surface. Once all the clear parts were installed, I proceeded to apply CA along the seam lines and let cure. Next, I used a metal file to smooth the canopy frame seams. I find that using a metal file allows for more control since it is rigid you can file one frame at a time and not accidentally file nearby frames or clear panels. Once done, I proceeded to mask each clear panel with Tamiya tape.

For the turret assembly, I wanted to glue all the interior piece together and paint the turret canopy separately. Per the instructions, this can not be done since the parts will not fit past the turret base opening if the seat and gun are assembled first. The work around for this was to cut the two vertical side supports to have room to maneuver past the base opening and then reglue the vertical supports. Note, once the turret is installed it is impossible to see those vertical supports.

When it came time to paint the plane itself, I airbrushed the model with Mr. Surfacer 1000 gray primer. After this, I used Mr. Surfacer Black Primer 1500 on the underside. This was followed by Tamiya XF-75 (IJN Gray-Kure Arsenal) and XF-81 (Dark Green 2-RAF) for the upper camouflage pattern. A coat of clear gloss was brush applied for areas where decals would be located.

Kit decals from ICM are thin and somewhat brittle. I used cold water and looking back I should have used warm water to allow the decal to become more flexible. Decals were applied and settled down nicely with help from Microsol and Solvaset. During this process I used a cotton bud to help roll out the decal to compress it over recessed and raised surface detail. Once dry, I airbrushed a protective coat of Vallejo Clear Satin.

Next, I subtly weathered using ground up charcoal applied with a soft brush. This was followed by an airbrush coat of AK Ultra Matt Clear to seal it all in. Any charcoal weathering that was lost from the last clear coat was lightly re-applied.

Lastly, I installed the arial wire (Infini Fine Line) use CA to bond it in place and called it good.

Conclusions

The ICM Bristol Beaufort is a great kit. This is big 2-engine British bomber when completed. Due to all the small parts and multipiece nose canopy, I recommend this kit to builders who have a few kits under their belt. The parts fit great together with no trouble. With some patience during canopy masking and careful test-fitting before gluing, a nice WWII British 2-engine bomber will grace your collection in the end.

I want to thank ICM for providing this wonderful Bristol Beaufort Mk. I kit and IPMS/USA for allowing me the opportunity to review.

Highly Recommend!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews