De Havilland Mosquito FB Mk VI: The Build - Part 2

Thank you to Tamiya, Inc. for providing this excellent kit for review and to the IPMS Reviewer Corps for allowing me to document my build experiences. Sharing this review with the scale modeling community would not be possible without the exceptional support of the IPMS Reviewer Corps. Thank you everyone!

The Mosquito is one of my favorite aircraft with its underdog success story and stunning operational history. Tamiya’s representation of the fighter-bomber version of the Mosquito is superb. Please refer to an earlier IPMS pre-build review of this kit that describes the richness of the kit parts, decals, photo etch materials, instructions and research documents.

Summary

The following review details a very enjoyable build of a de Havilland Mosquito FB Mk.IV aircraft. A detailed build log and reference list follows this summary section. The entire build process was almost entirely without problem, extended over a few months with a full-time job competing with my time. The project was an excellent escape and reminder of something this hobby is really good for. I never found myself frustrated and was always absorbed in the kit. Tamiya clearly engineered this kit for trouble-free construction. The kit cross-referenced very well with published materials.

I opted for version A, HX922, the RNZAF aircraft from 487 Squadron, as flown in Operation Jericho. The mission resulted in a POW prison break at Ameins on 18 FEB 44 and is one of the Mosquito’s many epic stories. I also decided to display the aircraft on the ground with the flight deck access hatch open, ladder extended, nose gun compartment and nacelle covers off. While I plan to show off the extraordinary detailing of the engines and guns with everything open (there are magnetic latches to hold the panels in place should I change my mind,) I can’t use the highly detailed aircrew, after all, if the plane is all opened up, the pilot and the navigator would not be in the cockpit. Tamiya provides clear parts to allow the engines to be visible in the nacelles.

I proofed the instructions by proceeding in a linear fashion step-by-step and I found everything to be very straight forward, with the following caveat. My biggest problems had nothing to do with the kit, but were failures to notice part modifications called for in the instructions. I often overlooked the little knife (trim) icon to my detriment, and sometimes I missed drill-out notes. It took some discipline to avoid shooting too far ahead on assemblies, missing version-specific needs, and it also took discipline to cross-check each step for completeness. The part fit is so good that it easy to get carried away and rush on! The sockets, tabs, notches, and so on for joining parts are molded to very tight tolerances with little to no cleanup required. Sprue attachment points are seldom in places where an imperfectly trimmed sprue remnant will affect part fit. I particularly like this because seemingly insignificant or incomplete cleanup errors are much less likely to accumulate or conspire to make bigger, more visible, and difficult to correct errors later. I did need to fill a gap in step 98, but I believe that is because of my fitting errors in an earlier step. I left off many assemblies until after airbrushing to reduce masking and possible damage.

Doing a detailed outline of the instructions might be overkill, but a thorough understanding of the assembly sequence may suggest which large subassemblies could be constructed somewhat independently. At the very least a good review of the instructions will highlight the subtle assembly differences in the 3 versions represented. There are large numbers of unused plastic and photo etch parts, suggesting different kit versions to be released in the future.

A very exciting aspect of the kit is the sheer number of small, highly-detailed parts. Many flaps, panels, engine parts, instruments, ordnance, framework and undercarriage parts are used. One advantage of all the small parts and subassemblies is that separate parts will allow more effective painting of individual components. I painted a great many parts on the sprues. This seemed to speed construction, but post-assembly touch-up was often needed. Listing out parts to be airbrushed on the sprues helped a great deal. I don’t always develop a detailed paint order or schedule for efficient airbrushing, but with this kit, it is worth taking time to do so. The intriguing magnets allow for simple drop-in part attachment, with removable panel display options. The underwing radiator covers work particularly well with the magnet positioning/placement.

A large number of decals are included, representing three markings choices and common stencils for each. I used Modelmaster acrylic gloss coat over Modelmaster acrylic color coats and experienced some silvering using Microscale solutions. I take credit for this problem, and suggest that a hard and thick coat of acrylic floor wax be used as a gloss-coat decal base. Solvaset did resolve many of the silvering issues. The stencils are very crisp. Some very nice features of the large national insignia and aircraft markings are notched and 2-piece decals. Correct decal positioning was quite effective with the notches and pieces, reducing decaling stress on the builder. Excellent stencils are included with the stencil positioning clearly indicated on a separate placement guide. The stencils are all readable under magnification. I am still astonished at the clarity of the air chart decal for the navigator’s chart board.

Conclusion

I can’t recommend this kit highly enough. There is no doubt that sticker shock is a factor with this new release, so I kept that perspective in mind throughout this review. One could buy many kits for $281 certainly, but the documentation, quality of the parts, excellent fit, high-level of detail, and pure build enjoyment make this kit well worth every cent. I am lucky to have built earlier Tamiya kits and this new Mosquito is indeed on a whole new level. This kit is certainly one of my most-fun builds to date.

Thank you again to Tamiya, Inc., and the IPMS Reviewer Corps! I appreciate everything you do for the hobby.

Build Log: Part 2

- Step 24

- Engine mount and landing gear starts here!

- Left and right engine mounts are slightly different.

- The right engine mount is constructed in steps 24 through 27

- Step 25

- No surprises, make sure the sockets of part J24 fit completely through firewall G18.

- Step 26

- Putting the hoses (P54) in is a little tricky, but the detail drawing really helps. Small notched tabs on the bottom of the hose near the top fit snugly on the mount frames and are great glue points.

- Step 27

- Should you forget to label left and right on the engine mounts, the key difference is in parts G18 and G19. G18 is for the right side and G19 is for the left side. The top edge of part G18 slopes upward to the right when looking forward at the bulkhead, and G19 slopes upward to the left.

- Note the J3 and J2 are on opposite sides on the left engine

- Step 28

- Same as 24

- Step 29

- Same as 25

- Step 30

- Same as 26

- Step 31

- Same as 27

- Note that parts J2, J3 are on opposite side as the right engine.

- Step 32

- The 4 exhaust assemblies consist of 8 pieces each.

- The pipes attached to the manifold (parts P46, P47) without any trouble.

- I found that attaching the pipes first, followed by the cap and small vent (P40, 41, and P37, 50) made for an easier process than the method shown on the instructions.

- Step 33

- No surprises here, but the oil tank fits very snugly on the back of the firewall, popping right into place with a bit of positioning.

- There are lots of pipes to position, and the pin ends fit well into the received socket on manifolds, etc.

- Step 34

- Engine nacelle interior PE rib detail and door hinges fit without a problem. Receiving notches for the PE ribs are very snug.

- Paint detailing here before assembly

- Step 35

- If you forget which nacelle halves are which, all four have unique features. G3 has one document pouch in the back of the wheel well, G2 has nothing, G3 has what looks like a lug wrench in the back part of the wheel well, and G4 has 2 document pouches in the back of the wheel well.

- Very solid fit!

- Step 36

- The engine coolant tank fits on the back of the firewall with a little bit of persuasion, and the key feature is a small notch on the prop plate that lines up with the bottom center midline of the engine. A detail drawing show this quite well in this step.

- Step 37

- Same as 34, with different nacelle halves.

- Step 38

- Same as 35, with different nacelle halves.

- Step 39

- Same as 36

- Step 40

- No fit problems with fit

- Modification based on final version required here, a minor part removal

- Step 41

- No fit problems with fit

- Modification based on final version required here, some drill-outs

- This kit has the “many boxes” approach in many areas, but everything fits well. Parts K22, 23, 25, 26 fit in slots, but it is possible to misalign them. Again, test fit for planning as much as snugness.

- Step 42

- No fit problems with fit

- Magnets dropped in easily

- PE grills look very nice

- Step 43

- No fit problems with fit

- Magnets dropped in easily

- PE grills look very nice.

- PE part folds are very nice, but because of the very thin fold lines, there is only a chance or two to get the fold right.

- Step 44

- Drill outs not to be missed, make sure you look carefully at the instructions and use the correct locations.

- Control surface hinge support structures are excellent.

- For a reviewer, this kit has been somewhat boring, meaning there have been virtually no significant corrections, modifications, and so on. Everything works and fits very well!

- The PE parts are magnetic, so be aware when working near the magnets.

- Step 45

- Eight self-tapping machine screws attach the wing root to the outer wing tops. A small narrow screw driver is included.

- Bomb rack drill-out locations for 2 mm holes are marked with molded-in arrows.

- PE grill frame parts a-19, a-17 popped into place without incident.

- Step 46

- Straightforward, excellent fit after leading edge attachment points trimmed per instructions.

- Step 47

- Aileron assembly with no problems

- Step 48

- Important to follow the order of ailerons first, then wingtip assembly.

- Step 49

- Tolerances are very tight on all of the parts here.

- The tanks fit very snugly in the wing spar. The supporting center rib, part R7, has a locating tab that fits into notch in the bottom of the spar bay. A possible alternative approach might be to fit R7 in the bay, where you can see if the tab is seated correctly, and then rotate the fuel tank assembly in. I did not do this, and I am not sure if there is enough room to do the rotation.

- Step 50

- The kit parts fit very well, with no surprises.

- Step 51

- Main landing gear is assembled here, with an intriguing approach. Each wheel and tire has 16 parts. I am not convince of the value of this approach, but the middle seam problem typical with wheel halves is eliminated. I still had lot of careful filing and trimming, but the overall effect is good.

- The tire parts may suggest that a different version of the kit is in the future.

- Step 52

- Held off until after painting main assembly, concerns over masking during the “big” painting.

- Step 53

- I mounted the engine nacelles without the main landing gear and associated braces

- Skipped to step 57

- Step 54

- Held off until after painting main assembly

- When I did come back to this step after the “big” painting, I was able to snugly dry-fit everything, then wick cement into the joints.

- Step 55

- Held off until after painting main assembly

- When I did come back to this step after the “big” painting, I was able to snugly dry-fit everything, then wick cement into the joints.

- Step 56

- Held off until after painting main assembly

- When I did come back to this step after the “big” painting, I was able to snugly dry-fit everything, then wick cement into the joints.

- Step 57

- When I did come back to this step after the “big” painting, I was able to snugly dry-fit everything, then wick cement into the joints.

- Step 58

- No surprises!

- Do not get any glue inside the machine nut well. The cap, part C3 can be glued from the outside.

- Step 59

- No surprises!

- The PE Gee receiver case has vent holes that really add to the effect. An ultra-detailer might be tempted to put glass tubes inside.

- Step 60

- This step was terrifying! Carefully follow the directions about inserting the wing and review the detail diagrams before starting.

- Part C-28 covers a screw that help hold the wing in position.

- A little bit of tweaking and judicious localized pressure is required to get the wing in place. The heart-stopping quiet pop of the wing going into position was a little unnerving. But the results of the effort were a nearly invisible wing-fuselage join that vanished with a touch of Tenax.

- Step 61

- Two 20 mm cannon ammunition boxes were completed in the step, with no troubles at all.

- Each box has 8 pieces.

- Don’t forget the drill-outs! (How do I know this, you should ask…)

- Step 62

- Be very careful with the facing direction for the parts. R1 and R8 have a forward-facing direction to pay attention to, and the curved side of the ammunition box lids faces aft.

- Be certain to put the ammunition box with the narrow-spaced drill holes on the forward side of the assembly. These drill holes are for the cannon mounts.

- Step 63

- Cannon assembly was very straight forward with no problems at all.

- The usual cautions about dry-fitting apply to parts Q2, 3, 15, and 16. The drums are not identical for each side.

- PE parts a-22 and a-42 are spacing jigs to help keep the barrels in alignment and is NOT to be glued in.

- The part fit is very snug, and I was able to save final gluing until after installation in the fuselage.

- Be very careful to trim off OPPOSITE sides of Q18; you will be in effect making a right and a left cannon in this step and the following step. The small cylinder section left behind after trimming is the attachment point for the heater hose in step 65.

- Step 64

- Same as previous

- Step 65

- I glued up the major pieces, but left the smaller parts (Q12) off until installation in the fuselage.

- Parts R11 and R12 are very similar, but have different curvature. R11 has a gentler curve or bend.

- Step 66

- Straight forward!

- Step 67

- No problems, but be very slow and careful getting the 20 mm barrels into the forward holes.

- The receiving holes for the mounting brackets are small, but the whole assembly fits very firmly. The tolerances are very close.

- The bombs fit without any problems as did the heating hose and a roller (part C18.)

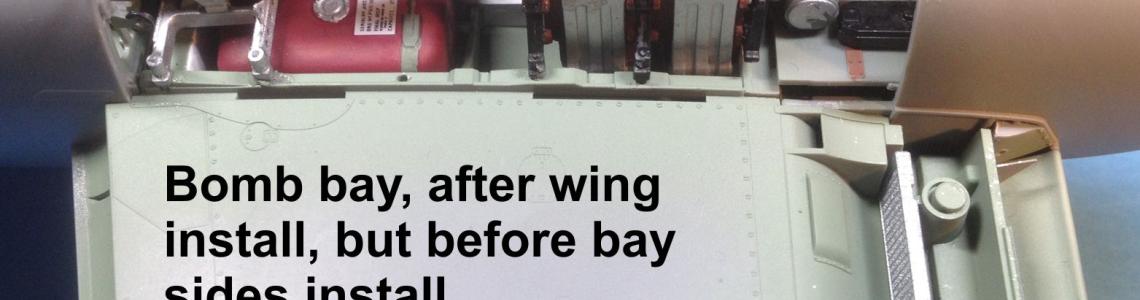

- Step 68

- Closed, half-open, or open bomb-bay is the choice that must made at this point in assembly.

- I chose open.

- I assembled everything as called for, with one exception. I did not attached T2 or T6. These two parts are door supports. By leaving them off, masking will be much easier.

- Step 69

- A mere trim for Version A!

- Step 70

- Skipped, for closed bomb bay

- Step 71

- Skipped, for closed bomb bay

- Step 72

- Skipped, for closed bomb bay

- Step 73

- Skipped, for half-open bomb bay

- Step 74

- Skipped, for half-open bomb bay

- Step 75

- Skipped, for half-open bomb bay

- Step 76

- Following installation of sides, I skipped ahead and completed everything else for “big” painting

- Parts C1 and T12 are easily fitted after installation of the fuselage sides.

- Step 77

- PE tools (1.25 inch open-end and a 3 inch spanner) are included for mounting on the inside door!

- PE chute dividers were a little tricky to align.

- Step 78

- Held off for post painting install

- Step 79

- Skipped, this step is for flaps up, I elected flaps down.

- Step 80

- Skipped, this step is for flaps up, I elected flaps down.

- Step 81

- Skipped, this step is for flaps up, I elected flaps down.

- Step 82

- Solid linkage bar of the flaps is very nice for alignment.

- A hook on the linkage bar lock into place on interior nacelle structure, precisely positioning the flaps down in the correct, or at least same angle!

- Step 83

- The flap hinges were a little tricky to get into position. I found that gluing the hinge on the flap first, followed by the hinge to the wing worked well. The PE flap plates (a-20, 21, 23, 24) dropped snugly into place and were easily secured by wicking CA into the joints.

- Step 84

- The next step calls for more magnets. It is not completely clear to me what the logic is after skimming ahead in the instruction a bit, but I have learned to have some faith in the instructions.

- Use of a clear plastic intake grill is odd, I would’ve thought this would be an easy PE part.

- Two magnets are used here, two surprisingly strong magnets; use toothpicks to prod them into position

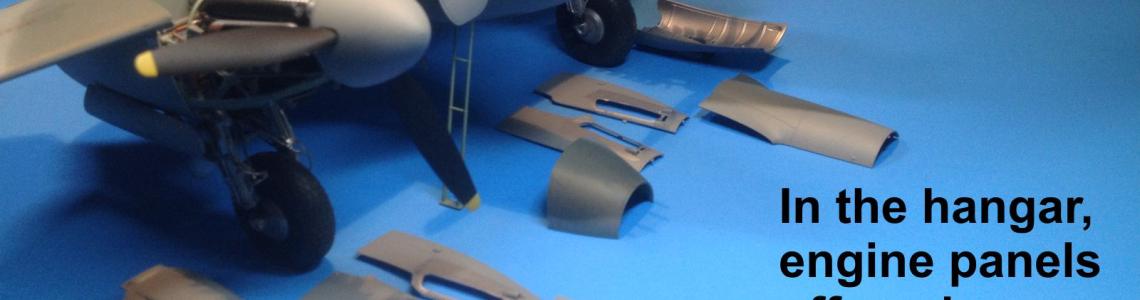

- Step 85

- Engine cowling sides had no surprises.

- Version A sides are different that B and C.

- Step 86

- Fitting the sides is a little bit tricky, this step will test how well the exhaust stacks are glued in.

- Step 87

- This step is really about placing the engine cowling undersides. The forward magnet holds to the metal plate (b-23) glued to the bottom of the engine in a previous step.

- I find it odd that the air duct is to be removed before installation, hence the magnet attachment. I do not recall anywhere that the instruction indication that the cowling panels can be removed for diorama or display purposes. So if the panel is to be shown on the ground, there is no problem with the air duct being inside the panel. However, if you are planning to show the top and side cowling panels off (like I am), I am pretty sure the air duct will need to be in place, since it will be visible from the sides.

- Step 88

- Step skipped, describes the flame damper construction for versions B and C.

- Step 89

- Step skipped, describes the flame damper construction for versions B and C.

- Step 90

- Prop construction: nothing unusual, make sure you get the correction version. Version C uses the paddle blades.

- Step 91

- Adding metal plate for magnets to top engine cowling panels and radiator flaps

- Step 92

- Fitting top engine cowling panel: the magnet arrangement works very well

- I did not mount the prop here, none of us would!!

- Step 93

- Radiator flaps fit very well and are securely held by the magnets.

- Step 94

- Bomb racks, no issues! Version C uses drop tanks.

- Step 95

- Bomb racks fit well on wings.

- Step 96

- Main landing covers consist of 2 pieces each for an excellent thickness. The bomb bay also has the same thickness quality.

- Step 97

- Mounting gear covers called for here, I held off attaching until later.

- Step 98

- Adding the 20 mm cover was the only place where I found I had a fit problem. Back in the nose assembly of step 16, I must have not quite gotten the tolerances right. There was about a 0.5 mm gap on both sides of the cover. I believe this is my construction error, not a design error, especially given the stellar parts fit up to this point. I don’t know where I blew it on this one!

- Step 99

- Canopy framing and details

- Step 100

- Framing parts fit very well

- Step 101

- I careful cut the masks from the sheet provided. Even with careful trimming, the canopy masks were slightly oversize and misshapen in some cases. I elected to use Bare-metal foil to mask the canopy. Die-cut masking patterns would be nice, and in-line with the excellent character of the kit.

- Step 102

- No issues with the tail fin and rudder.

- Step 103

- No fit issues!

- The canopy snugged down very well.

- No mast used with version A.

- Step 104

- I temporarily placed the hatch for painting, then detailed and added the parts after “big” painting.

- Part T22, the hatch hinges, are long enough and fit will enough into slot in the fuselage interior that no glue is required to hold the hatch in place.

- The ladder sit very securely, and does not require glue either.

- Step 105

- Skipped this step, since I did not use figures, which really is too bad. The three figures provided are very well detailed.

- Painting

- I copied and enlarged the color print for version A markings up to a 515 mm wingtip to wingtip measurement to create full-size paper masking templates.

- I painted the gray first.

- I cut masking templates from the enlargement and used them to cover the gray area and create a soft edge for the camo.

- Decals

- The national decals and specific aircraft markings should go on first. Many stencils overlie the larger insignia.

- I suggest looking carefully at the geometry of the decal location. If there are small nubs or other features that might interfere with positioning the decal, make sure that the clear carrier film is trimmed out for the potential problem area. Decal 31, the red KEEP OFF lines, is the best example. There is a small raised handle on the wing close to the cockpit on each side, with no decal cutout. Trimming a hole in the decal really helped with smoothing it into position

- I started with the aluminum decals around the exhausts to test how the decal would respond to Microscale solution. The decals seemed to respond well, but are very thin. The thinness is not a problem, but I tore some of the narrower decals. There is a fine balance to keeping the model surface just wet enough for positioning the decal without floating it.

- Decals 3 and 4 should be put on before any other fuselage decal. These decals are split to accommodate a fuselage spline on the right side and are very position-dependent. This makes them a critical reference point for lining up other fuselage decals.

References

- Franks, Richard A., 2013, The de Havilland Mosquito, A Comprehensive Guide for the Modeller, Second Edition, MDF 20, SAM Publications, ISBN 978-1-906959-3-33

- MacKay, Ron 1998, Walk Around, de Havilland Mosquito, Walk Around Number 15, Squadron/Signal Publications, ISBN 0-89747-396-5

- Scutts, Jerry, 1992, Mosquito in Action, Part 1, Aircraft Number 127, Squadron/Signal Publications, ISBN 0-89747-283-7

Comments

Your review of Tamiya 1/32 Mosquito

This is the best review I have ever come across on the web. It sure has helped me a lot in building the model as I have discovered several problems and mistakes I made in working with it. It makes my building a lot more enjoyable now as I go along.

Thank you, Alec

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews