De Havilland Mosquito FB Mk VI: The Build - Part 1

Thank you to Tamiya, Inc. for providing this excellent kit for review and to the IPMS Reviewer Corps for allowing me to document my build experiences. Sharing this review with the scale modeling community would not be possible without the exceptional support of the IPMS Reviewer Corps. Thank you everyone!

The Mosquito is one of my favorite aircraft with its underdog success story and stunning operational history. Tamiya’s representation of the fighter-bomber version of the Mosquito is superb. Please refer to an earlier IPMS pre-build review of this kit that describes the richness of the kit parts, decals, photo etch materials, instructions and research documents.

Summary

The following review details a very enjoyable build of a de Havilland Mosquito FB Mk.IV aircraft. A detailed build log and reference list follows this summary section. The entire build process was almost entirely without problem, extended over a few months with a full-time job competing with my time. The project was an excellent escape and reminder of something this hobby is really good for. I never found myself frustrated and was always absorbed in the kit. Tamiya clearly engineered this kit for trouble-free construction. The kit cross-referenced very well with published materials.

I opted for version A, HX922, the RNZAF aircraft from 487 Squadron, as flown in Operation Jericho. The mission resulted in a POW prison break at Ameins on 18 FEB 44 and is one of the Mosquito’s many epic stories. I also decided to display the aircraft on the ground with the flight deck access hatch open, ladder extended, nose gun compartment and nacelle covers off. While I plan to show off the extraordinary detailing of the engines and guns with everything open (there are magnetic latches to hold the panels in place should I change my mind,) I can’t use the highly detailed aircrew, after all, if the plane is all opened up, the pilot and the navigator would not be in the cockpit. Tamiya provides clear parts to allow the engines to be visible in the nacelles.

I proofed the instructions by proceeding in a linear fashion step-by-step and I found everything to be very straight forward, with the following caveat. My biggest problems had nothing to do with the kit, but were failures to notice part modifications called for in the instructions. I often overlooked the little knife (trim) icon to my detriment, and sometimes I missed drill-out notes. It took some discipline to avoid shooting too far ahead on assemblies, missing version-specific needs, and it also took discipline to cross-check each step for completeness. The part fit is so good that it easy to get carried away and rush on! The sockets, tabs, notches, and so on for joining parts are molded to very tight tolerances with little to no cleanup required. Sprue attachment points are seldom in places where an imperfectly trimmed sprue remnant will affect part fit. I particularly like this because seemingly insignificant or incomplete cleanup errors are much less likely to accumulate or conspire to make bigger, more visible, and difficult to correct errors later. I did need to fill a gap in step 98, but I believe that is because of my fitting errors in an earlier step. I left off many assemblies until after airbrushing to reduce masking and possible damage.

Doing a detailed outline of the instructions might be overkill, but a thorough understanding of the assembly sequence may suggest which large subassemblies could be constructed somewhat independently. At the very least a good review of the instructions will highlight the subtle assembly differences in the 3 versions represented. There are large numbers of unused plastic and photo etch parts, suggesting different kit versions to be released in the future.

A very exciting aspect of the kit is the sheer number of small, highly-detailed parts. Many flaps, panels, engine parts, instruments, ordnance, framework and undercarriage parts are used. One advantage of all the small parts and subassemblies is that separate parts will allow more effective painting of individual components. I painted a great many parts on the sprues. This seemed to speed construction, but post-assembly touch-up was often needed. Listing out parts to be airbrushed on the sprues helped a great deal. I don’t always develop a detailed paint order or schedule for efficient airbrushing, but with this kit, it is worth taking time to do so. The intriguing magnets allow for simple drop-in part attachment, with removable panel display options. The underwing radiator covers work particularly well with the magnet positioning/placement.

A large number of decals are included, representing three markings choices and common stencils for each. I used Modelmaster acrylic gloss coat over Modelmaster acrylic color coats and experienced some silvering using Microscale solutions. I take credit for this problem, and suggest that a hard and thick coat of acrylic floor wax be used as a gloss-coat decal base. Solvaset did resolve many of the silvering issues. The stencils are very crisp. Some very nice features of the large national insignia and aircraft markings are notched and 2-piece decals. Correct decal positioning was quite effective with the notches and pieces, reducing decaling stress on the builder. Excellent stencils are included with the stencil positioning clearly indicated on a separate placement guide. The stencils are all readable under magnification. I am still astonished at the clarity of the air chart decal for the navigator’s chart board.

Conclusion

I can’t recommend this kit highly enough. There is no doubt that sticker shock is a factor with this new release, so I kept that perspective in mind throughout this review. One could buy many kits for $281 certainly, but the documentation, quality of the parts, excellent fit, high-level of detail, and pure build enjoyment make this kit well worth every cent. I am lucky to have built earlier Tamiya kits and this new Mosquito is indeed on a whole new level. This kit is certainly one of my most-fun builds to date.

Thank you again to Tamiya, Inc., and the IPMS Reviewer Corps! I appreciate everything you do for the hobby.

Build Log: Part 1

Preconstruction work

- The build is straight-out-of-the-box, with modifications only as required in the instructions.

- There is a tremendous potential for extra detailing, and some aftermarket items are starting to appear for this kit.

- I discovered a wide range of color and configurations in researching.

- There are 320 parts, not all of which are used.

- Paint callouts and decal placement symbology for is a bit confusing, but use of letters for paint and numbers for decals really helps

- There is virtually no flash, but many small parts have light mold lines that are easily removed. I left most of them on if they would not be visible. The mold lines rarely interfered with fit.

- “Inverted assembly” instructions: the sequence is perfect for showing how parts go together, but make sure you dry fit and go through the larger assemblies completely. I found sometime that with the more complex groups I was able to modify things a bit to better suit my skills (!).

- The parts have very tight tolerances. In many cases, the alignment tabs on bulkheads, etc. benefit from sanding to reduce the depth. This allows just a little bit of wiggle room for later alignment

- Part arrangement on the sprues is good. Often all the parts for a step come from one or two sprues.

- I airbrushed as many parts as possible on the sprues, with later touch up as needed. Bare spots from removing parts were often covered during assembly.

- 38 plastic parts and 20 PE parts are not used

- 105 steps! But not all are used, depending on options

- Build options are:

- Closed, half-open, or open bomb bay! This allows a “buttoned-up” bay with no interior visible, or bombs in the after section in the “aft” open bomb bay, or bombs and guns in the completely open bay.

- Wing tanks or bombs

- I chose the following

- Option A

- Engines uncovered

- Open bomb bay

- Nose gun bay open: some photos show the top cover hinged on the right side and open (p. 47, MacKay, 1998) for something to consider later

- Boarding ladder extended

- No pilot or nav, sadly, they are very well done, but the model will not be in a flyable configuration

- Option A

- Interesting references to using tape for temporary placement of parts.

- Some assembly jigs provided for engine construction.

- Right and left engines are not the same, labeling them is suggested to avoid mismatch problems.

- Machine screws are used in the engine mounts, wing spar and fuselage.

- It may be possible to leave the main and tail gear strut off until after painting.

- A small paper insert describes a paint call-out correction in step 103.

- Don’t miss the decal callouts, the numbers are not quite as prominent on the instructions as the main parts.

- Painting notes for big colors:

- AS-9 Dark Green (RAF): I substituted Testors Acryl 4849 RAF Dark Green for the AS-9 spray can.

- AS-32 Medium Sea Grey 2 (RAF): I substituted Testors Acryl 4757 Neutral Gray FS36270 for the AS-32 spray can.

- Step 1

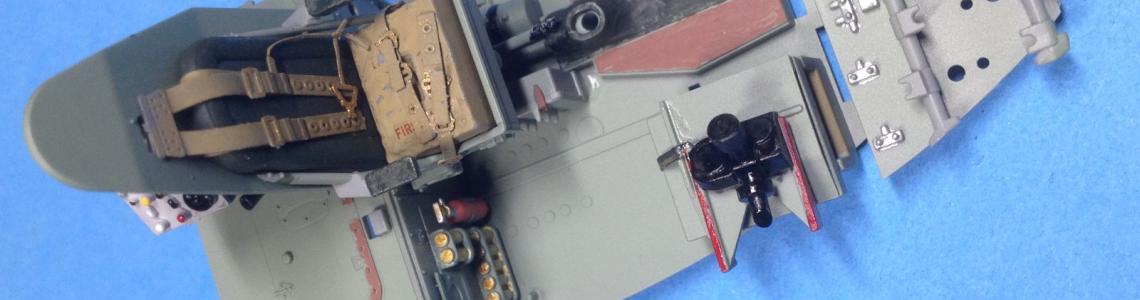

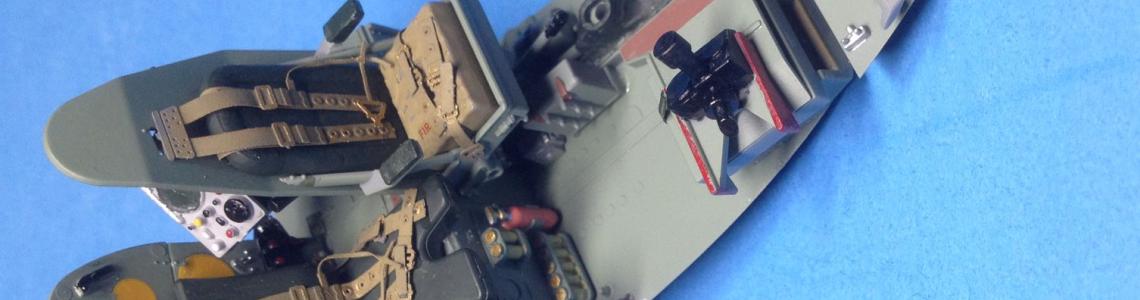

- 9 plastic parts for the pilot seat, 1 PE and 2 decals

- No fit issues

- Very crisp detail

- PE part a-14 has a top and bottom, the bottom edge has 2 very small holes that fit over dimples on U23

- Step 2

- First option choice time! Pilot/no pilot

- PE harnesses provided for both configs, with or without

- Flight crew PE parts are very malleable, folding very nicely into position.

- While there are a lot of parts, painting was achieved cleanly and effectively.

- Harness attachment points are small pins that fit over harness hardware for a snug glue joint.

- Only challenge was using two tweezers for several parts! Practice assembly before glue.

- Step 3

- Many parts in this step, but all fit well and only the tiniest amounts of flash needed to be scrapped off.

- I noticed that Tamiya black-green (XF-27) had almost a wax-paper response beading up when brush painted over airbrushed Testors Modelmaster acryl RAF interior green (4850). There was plenty of time for the Testors to cure and thoroughly dry, and the parts were washed. I will try a light wash of Poly S Plastic prep next time these two paints go together. A solution might be as simple as sticking with to one paint brand.

- I mixed up stencils 135 and 134 in this step and the previous, so the first aid box isn’t labeled!

- I did not apply decal 137 since the decal represents a “hot” oscilloscope. I am modeling the aircraft on the ground, so the sensors would all be off. I painted the face dark green with a Future “screen.”

- I could glue some parts in place by wicking CA into the location holes from the bottom or back of the cockpit floor.

- Step 4

- The drift sight is a nicely designed assembly

- Parts U4 and U3 are keyed such that you cannot put them in the wrong way, and you can glue them from the bottom side.

- Ditto on U20 to U18.

- Step 5

- I used a micro punch to cut masking stickers “W”.

- I added part L14 to the back of L17 here rather than in step 6 as it seem easier to do at this time.

- Step 6

- No issues whatsoever

- Detail painting instructions need a little more callout detail on some parts.

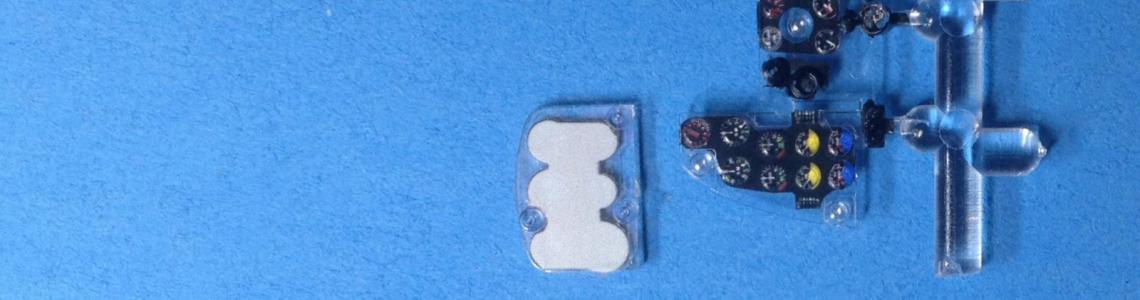

- Step 7

- The clear part-decal-PE panel face trio is superb.

- Instrument decals appears to be on simple silver film, but the film covers the face detail. The decals are designed for the instrument faces to show through the back of panels L12 and 13. An excellent effect is achieved by this design.

- Step 8

- No major problems

- If the control stick drawing was rotated a little bit, the drawing would have more clarity.

- Step 9

- A couple of major subassemblies go together here. Dry fitting is more useful for understanding the assembly sequences that the actual fit! A good example of this is the relationship between the cockpit floor, the forward bulkhead and the instrument panel assembly. Everything fits well in only one way, I found it possible to dry fit, then wick CA into the various tabs from below and the sides.

- The completion of this step was the first that I felt I had a solid piece of aircraft. Whew, a lot of parts, with a very satisfying early result.

- The building experience even at this early stage makes me consider this kit an excellent value.

- Step 10

- Very straight forward here, sort of…

- Note that the right and left version of each gun are built from the same guns but the discharge chutes are different. I suggest not adding the discharge chutes until later in step 11.

- Step 11

- The feed chute alignments are a little bit tricky.

- I think a more effective procedure is to glue up the ammunition box, including the top, mount the box on the bulkhead, and then sort out connecting the feed chutes to the guns. This will also allow you to get the discharge chutes on the correct side of each gun.

- Don’t forget to number the boxes with decals 121 through 124.

- Step 12

- No troubles at all, other than big fingers and small part management.

- Option C has some drill out requirements, and there are slightly different parts for each option.

- Step 13

- Gun sight choice for versions A/B or C

- Step 14

- Part U14, L10, T3, T7 were left off until post-painting to avoid break-off!

- Clear parts L7 x 3 were left off until post painting, to skip masking

- Decision point for closed, half open, or open bomb bay.

- Step 15

- Very solid tail wheel bulkhead, with tail wheel strut socket (good for post-painting addition AND swiveled position)

- Step 16

- Seam fit is impeccable on fuselage

- Do not forget cross-braces, parts T18, T19

- Some somewhat cryptic “remove” diagrams are shown for details around the dinghy hatch, but the raised detail is very small and easily taken off.

- The nose and top gun compartment hatch are to be temporarily taped in place, not quite sure why at this time.

- Step 17

- Only a few parts in this step

- Easy to place parts, then apply cement for final.

- Step 18

- Need to choose down or neutral elevator position here. I chose “down.”

- Be careful to insert the correct “hinges”.

- The joint is very solid with the elevator in place.

- Step 19

- Nothing unusual

- Saved tail wheel assembly for post painting

- This is a logical break point in assembly if you want to jump ahead to another assembly area.

- Step 20

- Tamiya’s practice of “square” sprue attachments is excellent, but make sure you follow the suggestions for trimming.

- Start of the engines! (and the first use of magnets)

- Note right and left engine distinctions start in this step.

- You will need a number of small metric drill bits here.

- I started labeling parts on the inside with a Sharpie to avoid confusion and mix ups.

- The magnets are very strong for their size; caution with steel tools! Nothing dangerous, the little suckers will leap off the bench onto your tweezers!

- Step 21

- I used Microscale liquitape to hold the machine nuts in place. I didn’t use CA since I did not want to clog the threads.

- All parts went together well with minor sprue point cleanup.

- Dry fitting is as important to understanding assembly as checking part fit.

- Step 22

- All parts went together well with minor sprue point cleanup.

- Dry fitting is as important to understanding assembly as checking part fit.

- Only one set of jigs for aligning the cylinders is provided, but assembly was not slowed.

- Step 23

- All parts went together well with minor sprue point cleanup.

- Dry fitting is as important to understanding assembly as checking part fit.

This is a logical break point in assembly if you want to jump ahead to another assembly area.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews