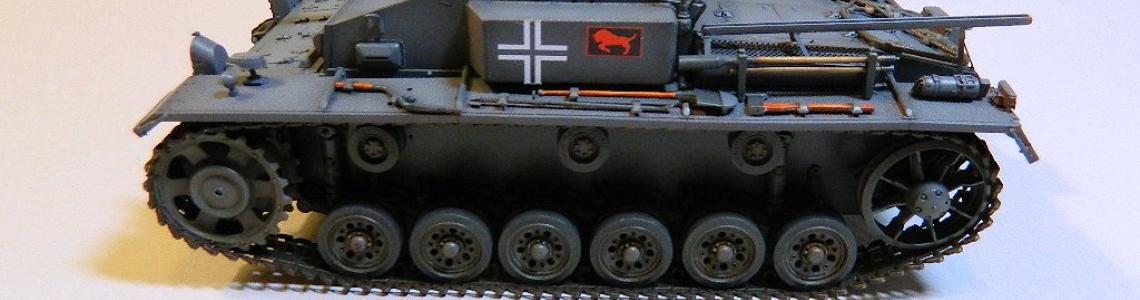

Sturmgeschutze III Ausf.E - Smart Kit

History Brief

The Sturmgeschütz III (StuG.III) Germany’s most widely produced AFV of WWII, with 10,619 eventually manufactured. Based on the chassis of the Panzer III, it was cheaper and faster to build since it did not have a rotating turret.

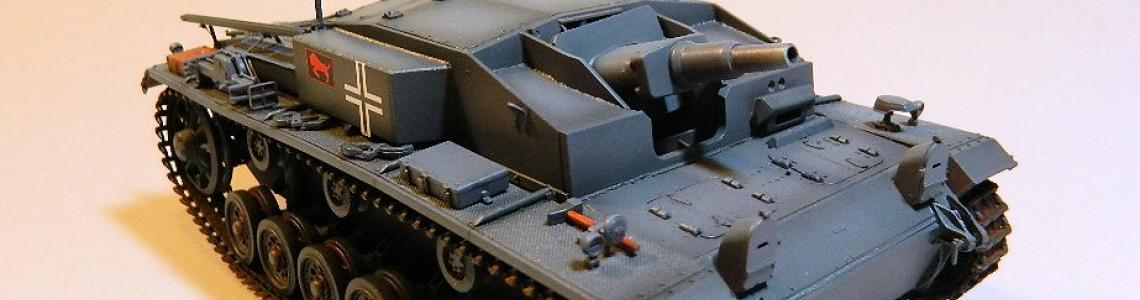

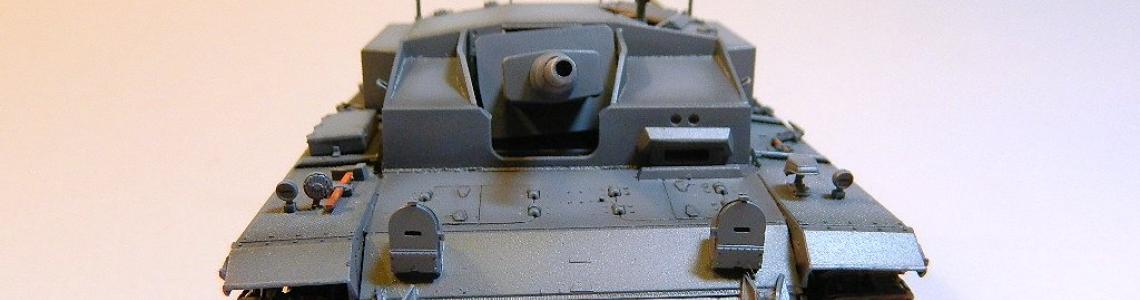

The Ausf.E, was armed with the short-barreled, low velocity 75mm StuK37 L/24 gun as preceding marks, and 284 vehicles were produced from September 1941 through to March 1942. This variant’s major improvement over its predecessor was a new armored pannier on the right side of the superstructure to accommodate radio equipment. Increased space inside allowed an extra six 75mm rounds for a total of 50 to be carried. An MG34 was stowed internally, and smaller hinges for the inspection hatches were another distinguishing feature of the Ausf.E.

The Kit

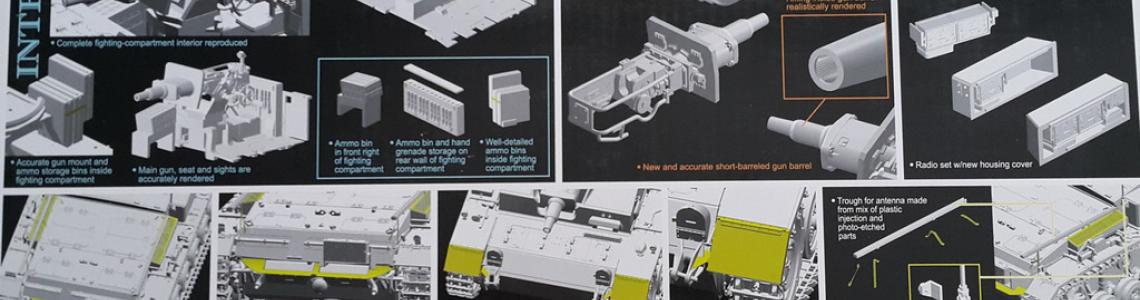

The kit includes 18 sprues of medium grey plastic, one clear sprue, DS tracks, a PE fret and decals. The photoetch fret is quite thin and did offer some challenges during the build. Instructions are typical Dragon and include 19 steps to the build, a sprue layout and profiles for five vehicles. All of the sprues are from previously issued kits, but one is new for this version. There will be plenty of surplus parts for the spares box.

Tracks are offered as the DS version. Detail is quite crisp, the horns are open, but there was a bit of flash on a few of the horns that will require removal.

The tools are molded separately and include finely molded clamps. No need for PE here! No crew figures are included in the kit.

Flash and sink marks were non-existent or quite minor for this kit.

Ejector pin marks and nodes do exist as typically found on Dragon kits, but none in this instance proved to be an issue with the build. Some of the nodes on the smaller parts do require careful removal and cleanup.

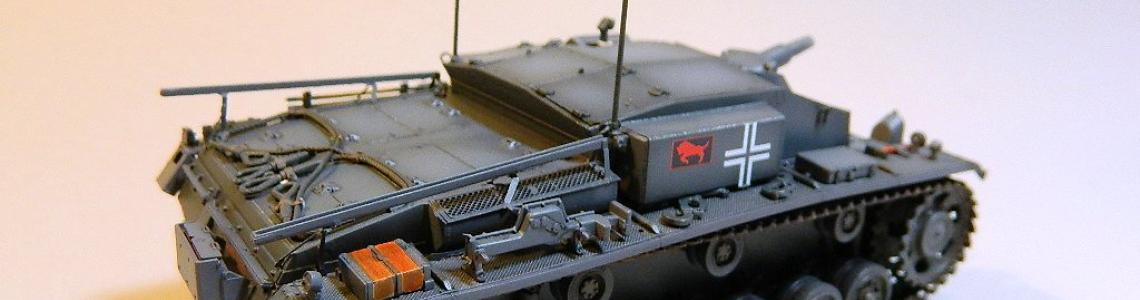

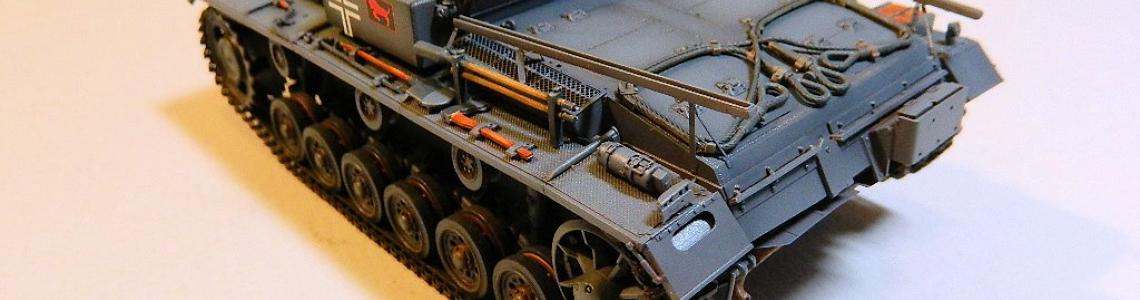

Weld beads are fine and will stand out nicely with some selective weathering. Tread plates on the fenders are finely detailed, but do appear a bit out of scale. A coat of paint and clear seal may tone them down.

In a few instances the parts attachment points wrapped around to the mating surfaces and required cleanup. This was generally the exception.

The tow cable is included as a plastic part intended to be mounted on the rear deck, however the instructions do not include this step.

Two jack blocks are included, but once again the instructions do not show them being used.

The Instructions

A sprue layout is noted showing the many parts that are not required for this build. The constructions steps are represented by exploded views with parts numbered that will require some review before beginning the actual assembly. Directional arrows show where parts fit together, and sometimes this can be a bit vague, but like I say review the subsequent steps for clarification of the fit. There is a legend that depicts advice and warnings for the builder. A paint and color legend is also included and is based on GSI acrylic and lacquer paints. Details to be removed from various parts are shown in dark blue.

Dragon instructions are generally busy affairs and require the builder to careful study each step and placement of parts. Sometimes the actual placement and location of parts is not clear and test fitting is encouraged.

Construction

I used Tamiya thin cement for the plastic parts, Gator glue to place the PE parts, and a thin or gel super glue to fix them in place permanently. Painting was done with Tamiya acrylic paints.

The first three steps deal with the hull and running gear. The first step show the idler adjustment being fixed to the rear idlers: since the kit includes one piece DS tracks, some adjustment may be necessary, so I thought it best if held off installing the idler adjustment until the running gear and tracks were ready for installation. Step 1 shows PE parts MA3 being glued to the inside of each idler wheel. The PE part is depicted as a ring. Well, it was not. Each "ring" (part MA3) consists of three segments that must be individually glued in place. I used Gator Glue to place each segment and allow for some adjustment. The placement of the last segment resulted is a small gap between the two adjacent parts, but additional tweaking eliminated the gap. Also, in step 2 the drive housing is shown being fitted to the drive sprockets. I glued the housing to the hull since I normally paint the sprockets and wheels separate from the hull. The hull front, part S38 should be glued in place before parts S39/S37 to avoid any significant gap between these parts. There was a small gap anyway, so I filled that with acrylic putty.

There was no positive locators for the front return roller housings, so I eyeballed the placement and it looked OK once glued in place.

On Dragon kits I found the fit between the road wheels and swing arm axels is quite exact. Any paint on the axels make the fitting of road wheel difficult. I wrapped the axels with a short length of Tamiya tape to protect them from primer and paint later.

In steps 7 and 8 the instructions show the front fender flaps being removed and photoetch parts being used to replace the flaps. I see this as the builder's choice, and I chose not to use the PE for this detail. I thought the plastic part details were sufficient.

Hatches are provided as separate parts and may be posed open or closed. The kit includes parts for the fighting compartment interior. If you want to leave the hatches open you will need to carefully plan the assembly and painting for the detailed interior. Construction for the interior is shown in steps 14-17. Test-fitting and some trimming of parts was required to have everything fit together.

Part C26 is the rear bulkhead of the crew compartment. This part slides vertically into two grooves on opposite sides of the hull. C26 proved to be a bit too wide for the space and required trimming of both sides before it would fit properly.

The sub detail for step 13 shows several tow cable clamps fixed to the engine deck, but there are no mounting holes provided. I decided to fit the tow cable with its molded on clamps instead. One cannot allow a perfectly good tow cable to go unused! The various hatches for the engine deck were glued in place and the gaps were filled with Mr Surfacer 500. The interior plenums of the radiator intakes were painted black before the PE grills were fixed in place with Gator Glue.

In step 18 the hull bottom, fenders, hull top, transmission deck and engine deck all come together. I first fitted the fenders in place and found that some careful placement of clamps was required to assure a tight fit. I allowed the solvent to dry for one day for each side before moving on with the top parts. The engine deck was next and this went on without issue. The transmission deck has two triangular tabs where the deck abuts the vertical front of the crew compartment. These tabs appear to be destined to fit in two openings in the fenders. For some reason I found the tabs would fit into the opening and the deck road high, and if they did the transmission cover and lower hull front would not meet. I cut the two tabs off and test fit the deck again, and again something was not quite right. Some sanding, scraping and test fitting resolved the issue.

I glued the ends of the DS tracks together and used wood clothes pins the hold the join. The tracks were set aside for a day to thoroughly cure. At the end of this time the tracks were found to be sturdy and never presented an issue during painting or fitting in place. I fitted the tracks, road wheels, return rollers, sprocket and return idler in place after the painting was completed.

Step 19 addresses the mounting of the two antenna trays at the rear sides of the vehicle. The detail is comprised of plastic and fine PE support parts. Careful bending of the E parts is required to get everything to fit just right. This proved to be a challenge, but with planning and care can be done.. I did drill out the antenna mounts and antenna bases, adding a small length of brass wire for a positive fit between the two parts. Super glue was used to attach the antennae to the bases.

Painting and Finishing Touches

I first painted the model with red oxide primer (a Tamiya mix), and a set it aside for 24 hours to properly cure. The finish painting was completed using Tamiya acrylic paints, again mixed for the RAL 7021 panzer grey. The model was given three coats of Future as prepartaion for the application of the decals and washes. After the application of the markings everything was sealed with a coat of Model Master flat acryl .

The assembled tracks were first airbrushed with a Tamiya mix of black and brown, and then a thinned application of dark earth. A wash made from burnt umber oil paint and odorless thinner was applied over the tracks to add "depth". A graphite rub was applied to the wearing surfaces. Everything was sealed with Model Master flat acrylic.

Once the tracks were thoroughly dry, the running gear and tracks were assembled. I first glued the road wheels in place and allowed them to dry for a day. Next I dry-fit the sprockets in place and placed the tracks of the sprockets, making certain the teeth were well seated in the tracks. The horns were fitted between the road wheels and the rear idler was fit in place. Both the sprockets and rear idlers were fitted without benefit of glue. Leaving the sprocket loose allowed for some possible adjustments during the fitting process. The last step was to glue the individual return rollers in place, matching each with the track horns. Once finished the tracks wrapped around the individual running gear components and appeared tight and realistic. The tracks themselves were not glued in place.

Decals

The decals are printed by Cartograf with marking for five different vehicles. I chose to use the markings for the Panzer grey vehicle from StuG. Abt 191, Klin, Russia. Only four of the markings were used for this subject, and all were placed on perfectly flat surfaces. The decals went on without issue. The carrier film was minimal and virtually disappeared once in place. The clear flat finish sealed everything.

Conclusion

Dragon has offered several kits for the various Sturmgeschutz III variants over the years, and the Ausf E kit fills the gap of the important World War II AFV. The kit is typically Dragon: many small parts, with several parts being required for specific sub-assemblies. Lots of great detail. The builder needs to review each construction step closely, test fit parts when applicable, and look ahead to the next steps. In a few steps the part did not match the number noted, but that was no problem. This will not be a quick build thanks to the many small detail parts. Each tiny part requires careful removal from the sprue and cleanup before being fixed in place. Many parts are fit to the model without benefit of mounting tabs or locators.

This is not a kit for the inexperienced. It offers its share of challenges. Overall this is a fine kit and worthy of attention by the builder, which will result in time well spent and a great model to be added to any armor collection. I truly enjoyed this project and am pleased with the end results.

I wish to thank Dragon USA and IPMS//USA for the opportunity to build and review this model kit. This was a pleasurable build and I highly recommend this kit to any and all armor fans.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews