Russian 9K37M1 BUK

Background

The Buk missile system, Russian: "beech tree”, is a family of self-propelled, medium-range surface-to-air missile systems developed by the Soviet Union and its successor, the Russian Federation. The Buk system is designed to counter cruise missiles, smart bombs, fixed- and rotary-wing aircraft, and unmanned aerial vehicles.

The Buk-M1-2 transporter erector launcher and radar (TELAR) vehicle uses the GM-569 chassis designed and produced by JSC MMZ (Mytishchi). TELAR superstructure is a turret containing the fire control radar at the front and a launcher with four ready-to-fire missiles on top. Each TELAR is operated by a crew of four and is equipped with chemical, biological, radiological, and nuclear protection.

Meng Kit

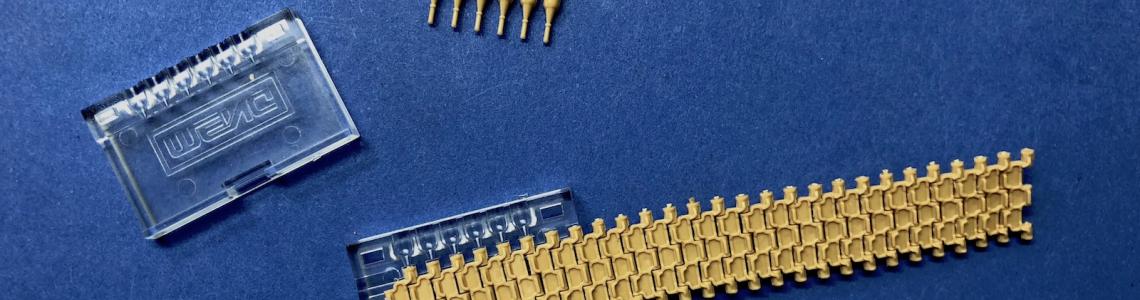

The kit futures movable suspension, workable tracks, movable missile launcher, and vinyl hoses. A track assembly jig is provided. The box says a PE painting mask for road wheels is provided, but it was not in the review kit sample. The many hatches on the vehicle can be posed open, but there is no interior detail provided with the kit. The kit is 263.6 mm long and 98.9 mm wide.

The kit comes in a 15” x 10” x 4” box with 10 sprues, all individually bagged by sprue type. The hull top and bottom pieces for both the lower and upper parts are bagged together. There is also a small stainless photoetch fret, decal sheet, vinyl hoses, clear plastic sprue, and a sprue with vinyl polycaps. The kit includes 615 plastic parts, 4 PE louvers, 24 polycaps and hoses, 240 tread pins, and one decal sheet

The parts have very nice detail and flash is not apparent. Most of the parts have very fine mold seams. There are some very small and thin pieces for pipes, rods, etc. The parts are molded in a beige desert sand color. Some of the sprue gateways are fairly large, but many of the gateways are on the backside of parts to ease cleanup. Detail on the parts is a very high quality.

The decals are for unit designations, vehicle numbers, and mostly warning labels. The photoetch fret contains four screens for grille openings. Meng uses notches, pins, crescent shaped holes, etc. to help align parts in the correct orientation.

Color profiles are provided for three units:

- Russian Air Force 1991-now

Green, Black, Sand Yellow - 9K37 BUK-M1, Ukrainian Army

Green, Yellow, Brown, Black - 9K37 BUK-M1, Finnish Army

Dark Green, Light Green, Brown, Black

Color profiles for two of the missile options are provided and show locations of the warning labels.

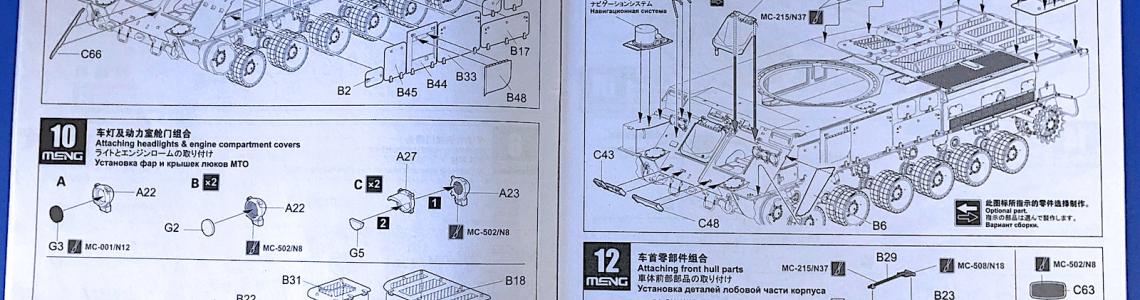

The instructions are a 6 ¾” x 10 1/4” stapled booklet with 28 pages and 38 assembly steps. A short description of the Buk missile system is provided in Chinese, English, Japanese, and Russian. Diagrams of each of the sprues and other parts are provided to assist in identification. Paint colors are called out in AK Interactive and Acrysion Color numbers. Detailed paint callouts are included with the instructions. The assembly diagrams are 3D exploded views that clearly call out the part numbers and locations. There are assembly variations for each of the marking options, so the version will need to be determined before assembly.

Assembly

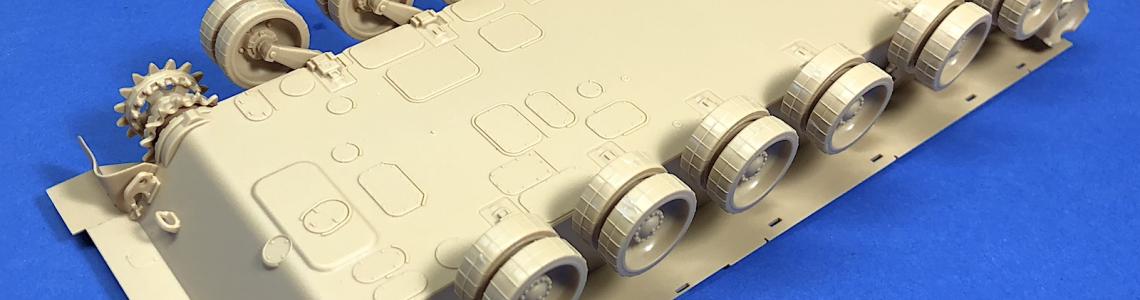

Steps 1 through 5 install the suspension and road wheels on the lower hull. Polycaps are used in the road wheels to allow the wheels to turn and makes it easy to remove the wheels for painting and installation of the tread. The fit of the track support wheels, parts A11, are a little loose so take care getting them aligned correctly. Step 4 installs the swingarms and torsion bars which will allow the suspension to operate. Step 5 installs the drive sprockets, idler wheel, and road wheels all of which can turn due to the polycaps.

Step 6 and 7 prepare the upper hull and attach it to the lower hull. This step is the first that shows different assembly modifications for the three marking options. The upper hull fits perfectly to the lower hull.

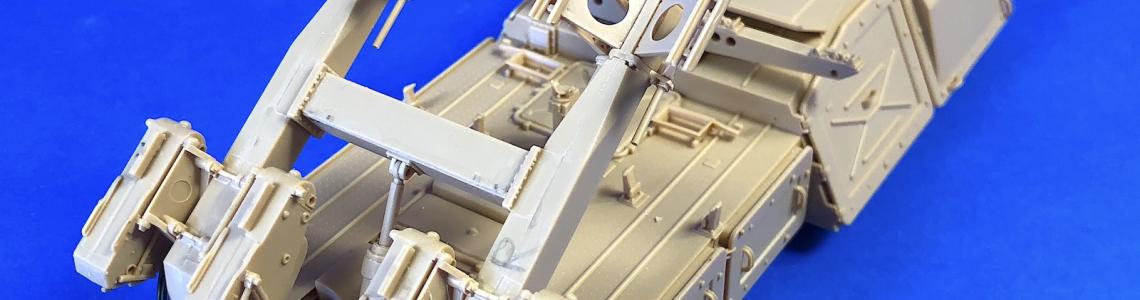

Steps 8 through 16 install the hull hatches (there’s lots of them) and other detail to the assembled hull. As the interior of the hull is empty I painted black behind the photoetch hatches and mesh screens. All of the hatches fit very nicely, and can be posed open on the hinges, although there is no interior detail for the hull. In step 12 the rearview mirror arm for options A&B has a tiny wingnut molded onto the arm. This reflects the very fine detail and molding quality of the kit. Options allow installation of the launching platform travel lock in either a raised locked position or a lowered position to allow the launch platform to rotate.

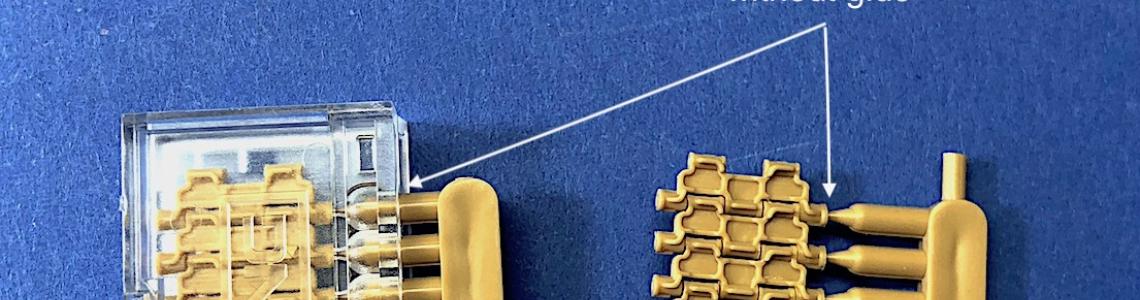

The tracks are assembled and mounted in step 17. Be careful removing the tread sections from the sprue to avoid damaging the pin sockets. This is important to allow the tread sections to snap together firmly. Meng provides a handy little jig for aligning 6 of the treads and holding them in place while the locking pins are inserted. The treads snap together on one side and then snap into the jig. Insert the end of the tread with the molded-on pin first into the previous tread section. Be careful to avoid damaging the molded-on pin as this is important to hold the assembled track together. Once all of the treads are placed in the bottom of the jig, the top of the jig is installed, and the locking pins are pressed into the treads while still attached to the sprue. It takes firm pressure to press the pins into place, but they will snap into place without gluing. The pins are then cut off after removing the tread section from the jig. The instructions call for 113 treads on each side of the tracks, which will result in a tight track without any sag. The track assembly jig and carefully avoiding damaging the pins will allow the entire 113 link tracks to be assembled and placed without any glue.

Steps 18 through 24 install the rocket launch platform. There are no assembly issues here and the fit of the parts is excellent. Note the areas not to be glued in the launcher lifting cylinder to allow the launcher to be raised.

The missile launcher racks are installed in steps 29 and 31. No assembly issues here either, and the polycaps allow the launch racks to be raised and lowered. The antenna lifting mechanism is installed in step 33 without issue.

Four missiles are provided with the kit and assembled in steps 36 and 37. The fit of the missile halves is good, and I was able to clean up the joint without filler. The last step 38 installs the rocket launch assembly to the lower hull.

Summary

This is an excellent kit and highly recommended. The fit of the parts is excellent, which simplifies assembly, and the detail on the vehicle is very impressive. In spite of the fairly large number of parts the only real assembly difficulty is assembling the track treads. Careful use of the jig and protecting the tread pins will help assemble and install the tracks in one section. The completed model allows the launcher to rotate, the missile racks to raise and lower, the antenna to raise and lower, and the optical sight assembly to rotate. A few small parts and the tricky tread assembly are the only difficulties with the kit so intermediate and advance modelers will enjoy this kit without too much difficulty.

Thanks to Meng Models for producing this excellent kit and providing the review sample to IPMS.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews