Russian Six-Wheel Army Truck with Shelter

Brief History

The most common all-wheel drive 6-wheel truck in the Soviet Army during the 1980s had a diesel engine and a cab-over-engine layout. Its serial production began in 1981 at a plant in Naberezhnye Chelny. The vehicle was distinguished by its high reliability and off-road capability. The basic model was intended, first of all, for the transportation of personnel or cargo up to 6 tons.

Since the mid-1980s, this truck for some time was the main transport base of the Soviet Army and the main middle-class vehicle for the installation of various types and purposes of superstructures. Variants with KUNGs are widespread – closed box bodies for the installation of special equipment and the transportation of personnel. One of these body types was the K4320D variant.

The Kit

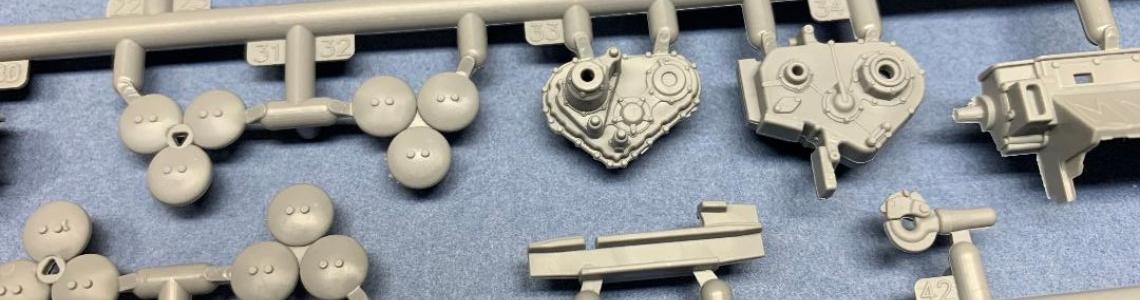

There are 363 parts to the kit, with all the sprues packaged in a single clear plastic bag. The clear parts are individually wrapped in clear plastic, and the small decal sheet was tucked into the instruction booklet. The parts are molded in a medium grey plastic, and the only ejector pin marks I found on my initial look-over appeared to be in concealed locations. A few of the parts had broken from the sprue tree and were loose in the bag. There is no photoetch included in the kit.

The parts appear to be chrisply molded with detail where appropriate.

This is my first ICM military vehicle kit and therefore was a new experience for me..

The Instructions

There are 36 pages to the bi-lingual instructions. The first page has a brief description of the vehicle, including tactical and technical specifications. A paint color chart is next with alpha/numeric codes for ICM, Revell and Tamiya paints. This is followed by a construction code (i.e. "cut off", "do not cement", etc). Parts sprues are shown on pages 2-5, with un-used parts high-lighted.

The instructions are exploded, line drawing views of the many sub-assemblies. Right off it became apparent the instructions must be thoroughly reviewed to understand the assembly and avoid mistakes. This is a very detailed and complicated kit. Looked like fun and challenging experience for me.

Construction and Painting

The Chassis, Suspension and Drive Train

Steps 1 through 15 address the construction of the chassis frame. First I would recommend that the main rails (parts A1 and A71) be prepared and ready for assembly before fixing any of the cross rails and members in place. Glueing the cross members in place on the left side main frame rail (part A1) then fixing the cross parts in place to the right side rail (Part 71) while the solvent is setting up and flexible will help assure proper alignment of the chassis. Most of the cross rails fit into sockets or pockets which help with the alignment, but there remains some play in the fit when the solvent is first applied. This assembly was allowed to harden over night.

The rear drive train is addressed in steps 34 though 44, and the drive train in steps 45 through 52. In steps 46 and 47 the locations for mounting parts F37 and F38 is not cear, and there appeared to be no attachment surfaces.I sort of winged it at this point. Later I did find a minor fit conflict with those parts and partsF16 and A15. Nothing serious, but none-the-less a conflict .

With steps 48-50 the modeler has two choice of rear axels, but there is no explanation for the differences. If the modeler wishes to has the front wheels turned to the right or left, chose the steps on the right side of the instructions sheet. I did not recognzed the difference and used the steps on the left side. Bummer! Need to pay attention. Building the model with the front wheels turnd right or left would present a more candid appearance.

Steps 56 through 58 show the assembly of the triple-mount tanks (compressed air?) The three cylinders are made of from three sides and the two end caps. I used a short length of masking tape rolled with the sticky side out, and fixed that loop to a flat surface. One of the tanks ends was placed on the tape and the three tank parts were fitted in place one-by-one and the solvent was then applied. Some adjusting was required to the fit of the tank parts to each other for proper alignment. Once aligned the remaining end cap was glued is place. The fun did not stop there. Each triple set of tanks had two triangular mounting straps that needed to be slipped over the end of the tanks, fitted into grooves and glued in place. This task went well, but care is required when removing these fine parts from the sprue. None of them broke for me during this build, but the potential for that to happen was there.

Step 69 shows the assembly of the spare tire rack that will be fit in place behind the crew cab. There are only two parts involved, but they were a challenge to fit the gluing surfaces together. The challenge was further compounded by the fact one of the parts was broken. Fortunately I had found the broken part earlier in the build and set it aside until I determined what it was and where it fit.

Engine

The engine assembly is shown in steps 16 though 26. Step 27 shows the engine fitting onto the previously assembled frame. I held that step until the engine and frame were first painted.

I primed the assembled engine with Tamiya XF-1 Flat Black, and once cured over night I applied Alclad ALC 10 Steel. A burnt umber oil wash was applied to punch out the details. The finished engine fit easily to the chassis and drive train.

Muffler and Exhaust System

Steps 30 though 32 cover the assembly of the muffler and exhaust pipes. Five parts are involved are require care in alignment. This assembly was allowed to harden over night. I stippled Mr Surfacer 500 over the parts to create a roughened surface prior to applying the paint. The parts were painted flat black, and once dry given a light dry brushing of burnt sienna oil paint to represent a rusted surface.

When it came time to fit the exhaust system in place I found I had to snake some of the pipes around parts of the chassis to get everything to fit in place. I applied solvent to the attachment point was was done.

Crew Cab

There are three crew seats in the cab. each seat is assembled from different numbered parts.The seat brackets that mount to the cab floor were each different. I made it a point the write the assembly step number to the underside of each seat so that I would know where each seat would be fitted in the cab once the seat assemblies were painted.

The instrument panel is made up from four parts, with the smaller parts being hand grips installed at each side of the panel (driver and passenger. The gages are represented by raised detail on the left side, with a decal provided for the various gages and buttons. I brush painted Future into the rectangual depression where the gages are located and allow that to cure for 48 hours. When it game time to apply the decall I cut out the instruments with the clear backer intact. After soaking the decals in warm water I realised the dials were all individual decals. The decals were then placed over the individual gages and given a coat of MicroSol to allow the decal to settle and conform. Had I recognised that the dials were individual I would have applied the ffuture only to the dial faces only. Live and learn.

The rear cab wall, part B32 had a number of ejector pin marks on the interior surface. There were the first pin marks that I noted on any of the parts. I was not certain if the marks would be visible in the final assembly and so I filled then and sanded the filler smooth.

The interior of the cab is noted as "neutral grey". I painted the interior surfaces of all the parts before assembly. I first painted a red oxide primer, applied a coat of hair spray, then the grey. Minimal chipping was created on the floor to show some wear.

The interior door hardware (window cranks and door handles are really quite small and require care when removing from the sprues. I used an acrylic glue to fit those tiny parts to the doors, and painted the parts semi-gloss black after the glue had cured. The two exterior rear view mirrors are each made from two parts and again require care when removing from the sprues. I did paint the mirrors semi-gloss black . The mirrors reflective surfaces were painted chrome silver which immediatly craized.

Shelter

The shelter construction consists of the floor, two ends, two sides, and the roof. The rear end and one side have doors that are intended to be fitted closed, but with some creativity could be fixed in an open position. There are also several small detailed panels that are fitted in place on the sides, which I assume are gun ports (??). These could also be fixed in open positions, but required the solid panel behind the ports to be opened and a hold open brace added. There is very limited detail inside the shelter: two raised areas that are perhaps bench seats.

Steps 118 and 119 address the construction and placement of the frame for the shelter box. Here I departed from the construction sequence. Each of the long side rails are made from two halves, with three cross braces forming the.frame. The attachment points for the cross beams to the long rails concerned me as a potential issue for misalignment betwwen the shelter and main chassis. I glued the long rails to the chassis frame, fitting the long rail tabs into the slots in the chassis frame. I then glued the three cross beams in place and was comfortable with the alignment.

Clear parts are provided for the doors and roof of the shelter. I left the clear parts off until after the painting was completed just to avoid having to mask those parts. The clear parts were installed using an acrylic glue.

Tires and Wheels

I was really torn with painting or not painting the rubber tires for this project. I did make it a point to wash the tires with Dawn detergent, and when dry I wiped them down with isopropyl alcohol. They really looked pretty good as they were. The tires have fantastic molded detail, that would make an off-road enthusiast envious.

The two part wheel hubs were painted before being fitted to the tires. I started with a home mix of red oxide primer. Once cured I applied a light coat of hair spray, followed by Tamiya XF-27. Once the green had dried I lightly washed the rims with a medium sized brush with the bristles dampened with tap water lifting off some of the green to represent chipping and wear.

The rear rims were inserted into the tires and then the outer rims were fitted in place. I applied Tamiya thick cement on the inside out the rear rim and fitted the outside rim in place. I could not tell if there was contact between the two plastic parts. but would hope for the best. There is a pretty solid connection between the rear axels and the rims, however the front wheel connection surface are rather meager. Again, I used Tamiya thick cement to attach the rims to the axels. I did the three wheels on one side, and rested the model on a flat surface on that side and allowed the joints to harden before doing the other side.

Final Assembly

The shelter is fitted to the chassis with six attachment locations. After this the crew cab may be fitted in place. Fitting the shelter to the chassis proved to be a bit of a challenge.The rear, horizontal support brackets fitted to the chassis were in conflict with the rear mud flaps. I needed the shelter to move about 1/32" to seat properly. I cut the rear support bracket off and just barely got the shelter to seat on the contact points on the chassis. I clamped the chassis and shelter together and applied super glue to hold them together.

There are two options for the cab: The first is the normal over-the road or driving position. The second is a tilt position. With all the detail offered with the engine and chassis I elected to go with the tilt position with the side doors closed. There are two V shaped support parts that are glued to the cab frame to hold the cab in the tilt position, and are glued to notched molded into the cab frame. The attachment ends must be slightly trimmed to fit into the notches.

The side doors may be fitted open or closed. If the closed configuration is used the two, dog leg hinges on each door must be removed. I did find that when the doors are fitted in a closed position there was a good sized gap at the front. I appeared that I neglected to properly place part B33 (the cab front end sub assembly) which resulted in the gap at both front doors.

In my haste to take pictures of the completed model I neglected to install the two side rear view mirrors, the windshield wipers and the left side spot light. A rookie mistake!

Decals

The scheme that I chose to replicate had minimal markings: the instrument panel, and front and rear vehicle numbers. In fact all three schemes had minimal markings.

Conclusion

When this kit was first posted for review volunteers I did not have any interest in the subject, but later I took a deeper look into the kit. Not much glamour in a truck with a box on the back? The ICM product page offers a download of the kit instructions so I looked into that information. There are 36 pages for the instruction booklet, and there are 154 steps in the assembly, and 363 parts. That looked intriguing.

With the large number of parts included in the build it is important to test fit often and check alignment when ever possible. Any mistake in fit or alignment in a sub-assembly may cascade to a major problem later in the assembly. This is especially true for the chassis and drive train assemblies. The fit of parts is generally very good, but as with any complicated kit attention to fit and orientation is very important. Sometimes the complex-formed parts are challenging to hold to fit together before the solvent is applied: This will require some patience with the modeler to get the parts to fit together. The plastic seemed a bit soft, but caused no issues during the assembly, and may have worked to my advantage when removing parts from the sprues and the subsequent clean up of the attachment burrs.

There are many small parts that require care during removal and cleanup to avoid breakage. Overall fit of the parts was pretty good, and I found no issues with the fit other than the need to enlarge some openings as with the door hardware.

I searched the Internet to find the cost for this kit, but none of the on-line vendors had the model in their catalogue at the time of this review. I did find a similar ICM six-wheel Russian truck in 1/35th scale that has a MSRP of $74.99, but could be purchased from that vendor for $53.99 plus S/H.

Overall, this is an excellent kit, that offers many hours of enjoyment during the assembly and painting. No glamor subject, but a very nice model to add to the display shelf. There is plenty of detail where required. I enjoyed the build and recommend this kit for anyone interested in modern Russian military vehicles.

I wish to thank ICM and IPMS USA for the opportunity to build and review this kit. Defintely recommended.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews