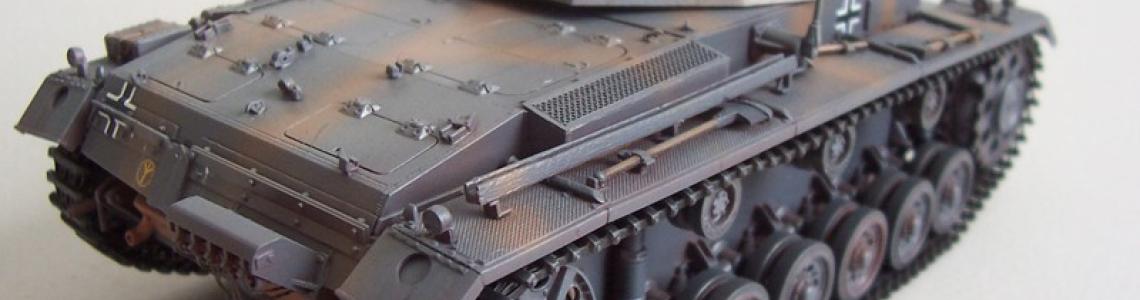

Pz. Kpfw. III Ausf E France 1940

HISTORY AND PERFORMANCE

The Pz. Kpfw. III Ausf. E was the first in the series to go into extended production. 96 vehicles were manufactured from December 1938 until October 1939. Additional armor was included, along with the standardization of six road wheels per side, while the main armament consisted of the 37 mm KwK L/46.5, along with two 7.92 mm MG34 mounted in the turret, plus a single 7.92 mm MG34 mounted in the front of the hull. This tank saw service in Poland, France, and Greece.

THE KIT

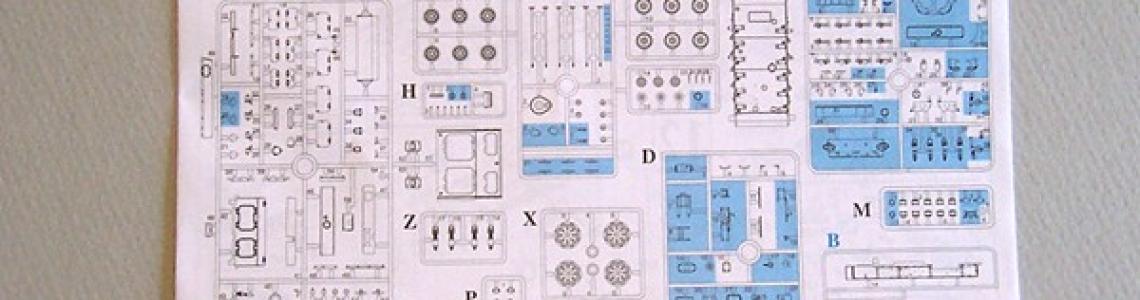

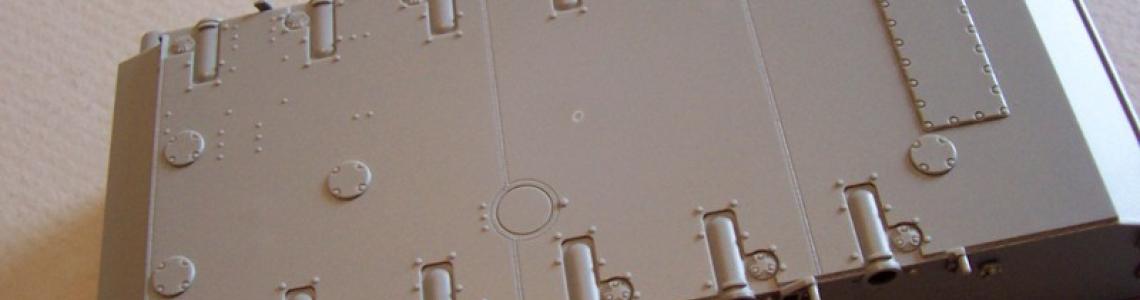

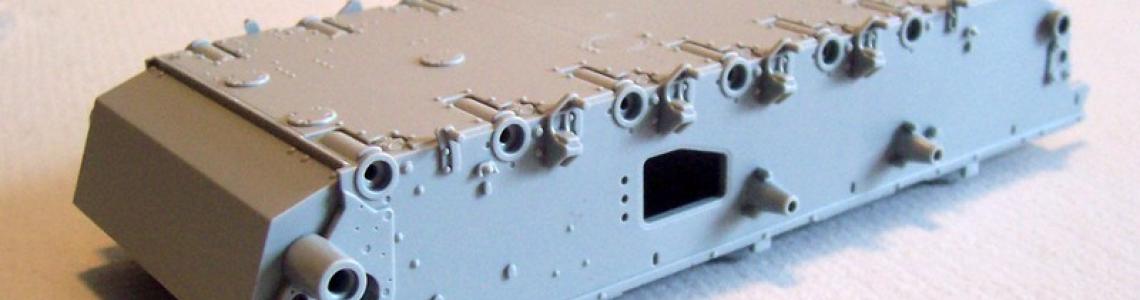

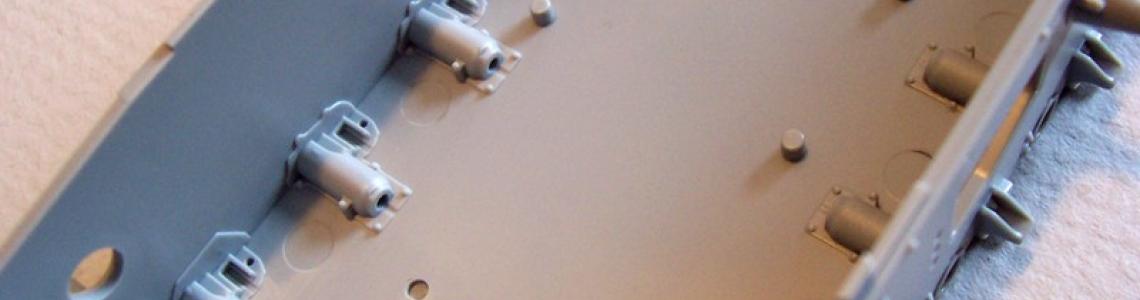

The kit is molded in the familiar grey, Dragon plastic. There are 23 grey plastic sprues, three clear sprues, the hull bottom and turret, a small photo etch fret, decals and two “metal parts“. The metal parts are packaged separately, and that is nice as these tend to get lost quite easily. The fenders are molded separate from the hull and include fine pattern detail on both the top and bottom surface, and no ejector pin marks. The welded seams are finely molded. The bottom of the hull is detailed with access ports. All tools are molded with clamps in place. All of the crew, transmission and engine hatches can be posed open, but there is no interior detail included.

- Instructions: The first page of the instructions show the sprue layout and identify the parts not to be used in this build. Do not remove these surplus parts until the build has been completed.Caution: Dragon continues with its reputation for busy and complex instructions. Study each step thoroughly and check ahead for clarification as necessary. On occasion parts are misidentified with the wrong sprue number.

- Sprues and packaging: There is no flash on any of the parts. The sprues are individually packaged.

- Clear parts: Clear parts are limited to the commander’s turret view ports ringing the cupola.

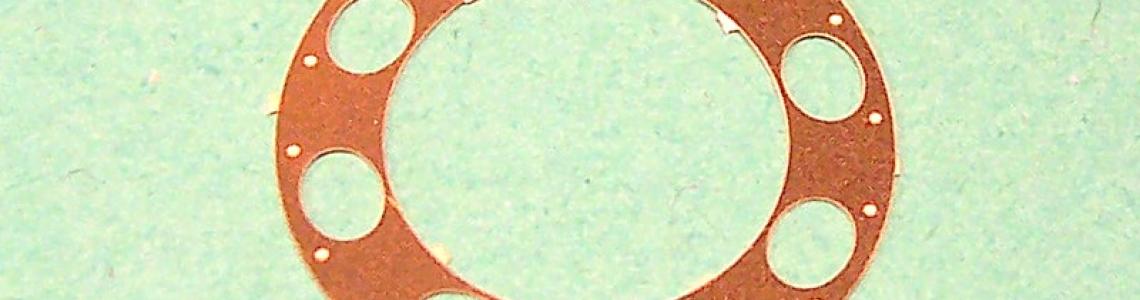

- Photo etch: There are four perforated rims for the rear idlers, a bracket for the jack, grilles for the engine cooling intakes, and some miscellaneous parts. Nothing too crazy.

- Figures: There are no figures included in this kit.

- Running Gear and Tracks: Individual links tracks are provided.

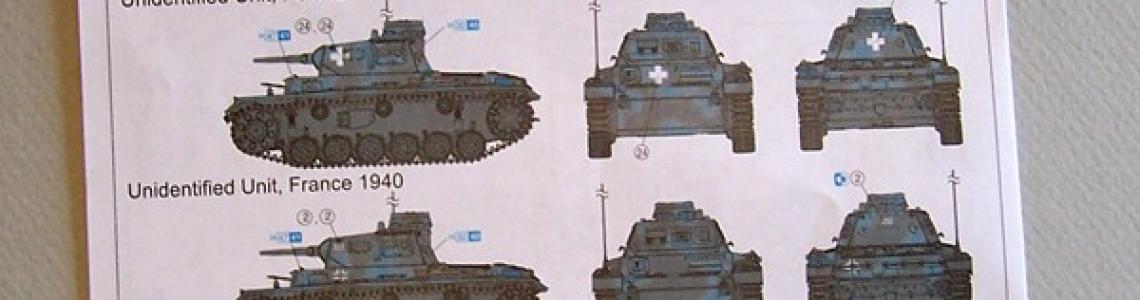

- Decals/Markings: Markings for seven vehicles are provided, including five that operated in France, one in Poland and one Greek veteran. The Greek campaign vehicle is the only all grey tank, while the others are grey and brown. This second color is not identified on the paint chart.

CONSTRUCTION

- Lower Hull: Step 3 begins the busy part of the build. Part S38 (hull front, lower section) should be fixed in place before Parts S39 and S37. If the sequence is reversed, part S38 is difficult to install without a mini pry bar. Every part fit perfectly in this step. With the only difficulty being of my own doing (Parts S37, S38 and S39 sequence).The subassembly shown for Step 6 is where I had my first problem. I lost part V35 as I began to prepare it before placement. This part would have been concealed behind part V28, so the loss was of no consequence. The placement of part V12 was not clear at all in the instructions, but looking ahead to the exploded view in Step 6 the orientation became clearer (see upper hull comments). When it came time to fit the small subassembly to the rear of the hull I found it to be a bit too wide. I carefully shaved a bit off each side, plus I needed to trim two sides of the ribs on the back side of part V41. Once the trimming was completed the parts fit.

- Upper Hull-step 9 shows the assembly for the engine deck. Initially, I did not realize that the deck-mount side of the access door cover hinges are separate items. The instructions show them in place on the deck. After cleaning up the individual doors I fixed the tiny male hinges (parts A63) to the hinges molded to the doors and fitted the doors to the deck. The tiny hinges were then pushed down to the deck surface and the solvent applied. No problems with alignment here with this method.

- Once the hull was completed I test-fitted it to the lower hull. Immediately I saw there were noticeable gaps on the sides near the rear. Parts V48 and V49 installed in step 6 had a number of rivet head on the back side, and these conflicted with the placement of the engine deck assembly. The rivets were trimmed off with a hobby knife and the rear deck fit perfectly. Step 16 shows the fitting of the lower hull with the three upper hull subassemblies and fenders. Although not shown, there is a sequence to get everything to fit properly. I fitted the front section of the upper hull first, then the fenders. The center section was next, followed by the engine deck. Check often for alignment and gaps. There will be a big sigh of relief when these various subassemblies fit together. Set everything aside over night to harden.

- Turret and Armament: The assembly of the commander’s cupola is shown in step 13. This is a busy assembly. I had difficulty with fixing Parts Q2 (there are five on them) to the ring base, Part Q9. Q2 would not fit with Q9, so I removed the five tabs from Q9. Rather than fix the Q2 parts to the ring base as shown on the instructions I placed them individually within the cupola, Part U. The first four were set in place, aligning each with their respective view ports and set with solvent. I knew the last one would be a tight fit, and it was, but it did go into position without too many colorful phrases used as encouragement. Parts Q3 and Q5 (five of each) were next fitted and set with solvent. These parts fit in place with no problems. The main and secondary armaments are very detailed with many small parts. I did not spend much time with either as I planned to close the turret hatches, but even with hatches left open very little, if any, of the interior detail would be visible. Step 14 addresses the assembly of the mantle and installation of the weapons. The parts all fit with precision, but when applying the solvent one must be very careful to avoid gluing all the moveable parts in place.

- The periscope: Part S30, fits on the left side of the turret roof. There is a surface-molded flange that surrounds the base of the periscope, but there is also an opening in the turret roof within the flange. This opening is slightly larger than the periscope base, and the periscope, Part S30, will fall through the opening. I glued a small square of sheet plastic on the bottom of the turret roof immediately below the opening, then punched a small disc of sheet styrene as a shim for the scope to set on. This worked.

- Running Gear and Tracks: the road wheels, sprocket and rear idler fit with no problems, and the individual links tracks took some time to clean up and fit together, but the effort was worth it. The rear idlers are a combination of plastic and PE parts. The PE parts to be used consist of two, perforated rings per idlers. The tag ends from the PE fret must be carefully removed before fitting the metal to the plastic parts. Once the assembly is completed the PE detail become difficult to see, but the builder will know that he finished a challenging piece of work.

FINISHING/PAINTING

I always wanted to do a Panzer III in something other than Panzer grey or Afrika Korps sand. I painted the model with Gunze Sango acrylic paints, used an oil wash and Model Master Acryl gloss and flat for the finishing touches. I used highly thinned Tamiya Buff to tone down the colors before the final flat seal coat.

DECALS

The decals went on over a glossy finish with no problems. I used MicroSol on the turret numbers to get them to lay down over the side view ports. There is no noticeable film whatsoever.

CONCLUSION

These kits are quite nicely detailed and engineered, and therefore everything fits quite well, but checking the work often will avoid possible problems later. This is my fourth Dragon Pz. Kpfw III, and either the kits are getting better, or I am (??!!). I do believe that Dragon does got a bit far with the number of small parts, total part count and the complicated instructions.

The builder should study the instructions closely before committing solvent to the joins. Test-fit everything and watch the alignment. Interestingly enough, the images on the box top and bottom often clarify certain details when the instructions are vague. Study the instructions and the box.

This kit is recommended for the experienced modeler due to the many small parts, detailed subassemblies and complicated instructions/construction. Watch makers and neurosurgeons will enjoy the small subassemblies. This kit will give the builder many hours of pleasure during the assembly process. Good references, plus the occasional peak at the box top, are also recommended to help clarify some of the less than clear details.

I thank Dragon USA and IPMS/USA for the opportunity to build and review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews