P-51B Birdcage

Eduard continues to expand its P-51 Mustang line, this time releasing the P-51B “Birdcage” in the Profipack box. In the box you get 7 plastic sprues (one clear), canopy masks, PE fret and a set of decal sheets with 6 possible camouflages, three of them in natural metal finish and 3 on camouflage finish of Olive Drab and Neutral Grey. All the options are in American markings.

Early in the construction phase you need to decide which version of the model you are going to build, as there are differences in the equipment located behind the pilot seat. To be honest, if you change your mind after you assembled the cockpit, it will be hard to tell you have the “wrong” equipment behind the pilot seat.

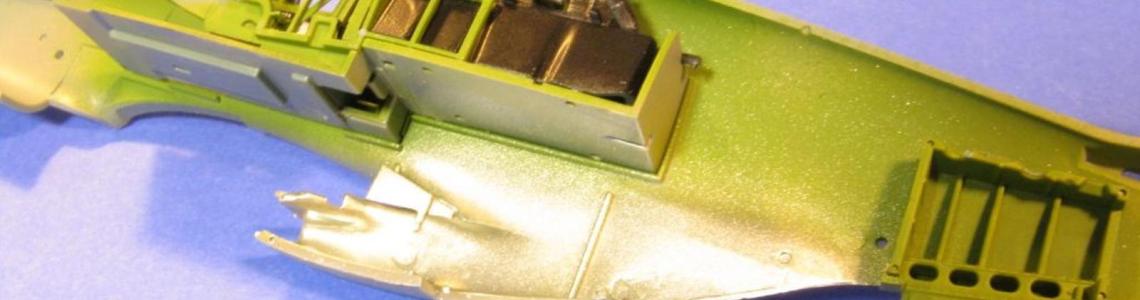

The cockpit and radiator are two models on its own and what a gem they are at that! Using the PE seatbelts and PE instrument panel enhances the look of the cockpit significantly. I did not have any real issue nor I can provide you with any advice or “gotchas” during the cockpit assembly. Just pay attention to the instructions, check your references for painting and you will have an outstanding cockpit, radiator area and equipment area behind the pilot.

When it is time to close the fuselage is when things get a bit more difficult. The instructions recommend gluing the sidewalls to the fuselage sides but while dry-fitting that step I thought it might create a challenge as the locations of the sidewalls on the interior of the fuselage sides is vague. Do not use the “shelf” in the inside of the fuselage to set the sidewalls! That little “shelf” is for the cockpit floor.

Instead, I would suggest you mounting the cockpit sidewalls to the cockpit floor/seat subassembly and then sandwich that “cockpit tub” in between the fuselage sides. You will have a nice “shelf” on the fuselage side to sit the cockpit tub to ensure alignment.

Also pay close attention to the instructions on how to mount the radiator in the belly of the model. There is a specific order to do it right. Just look at the instructions and you will be fine. But make sure you do look and understand the instructions!

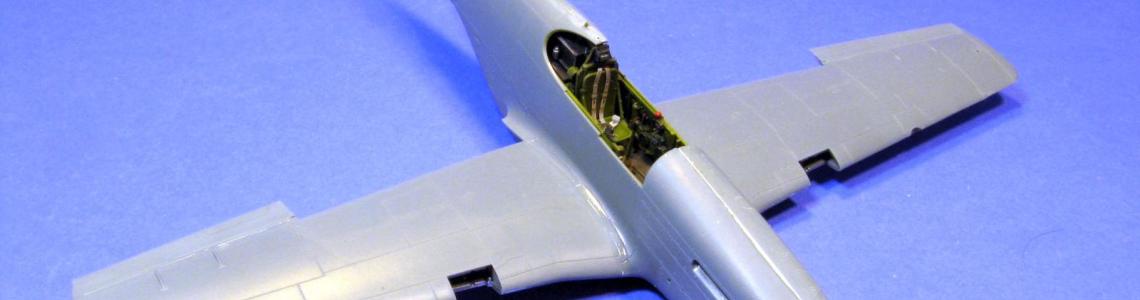

Before gluing/closing the fuselage, I recommend you to dry-fit the instrument panel (which can be added after the fuselage sides are closed) and ensure that it fits properly between the fuselage sides and that it does not flex the sides either. As part of the dry-fitting exercise, also dry fit part K4 (canopy windshield). I found that at that my IP was not properly seated in place and therefore part K4 won’t seat in place either. Dry-fitting allowed me to correct the position of the IP and saved me a headache later on.

A few notes: pieces S8 and S38 needed a tiny bit of filing to fit in place (they are installed in step C and D). They are in the fuselage-to-wing region. In step D, you can leave part S34 out until the very end of the assembly. Part S34 closes the nose of the fuselage and provides support for the propeller. I choose to keep that part out of the model as to be able to provide some support “from inside” the fuselage (using tweezers) when installing the exhausts, after painting and decaling.

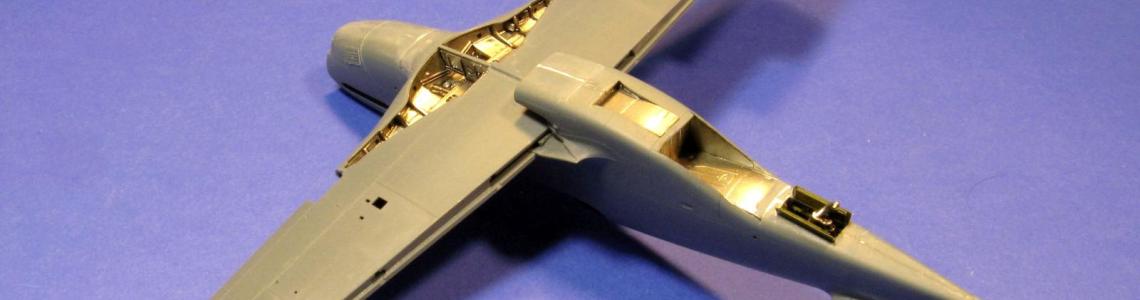

The wheel well is next, and it is probably the best detailed P-51 wheel well I have ever seen. It has over a dozen parts and you want to clean up the parts well (i.e. remove all ‘nubs’ from the pieces) to ensure proper alignment. You might want to dry-fit the landing gear at this time as well (I didn’t and there is more to come on that topic).

Once you have the wheel well taken care of, the instructions tell you to “sandwich” it between the wings. Make sure you have the landing light, ID lights (starboard wing) and gun barrels in place before gluing the top and bottom wings. Ailerons are separate parts and flaps are molded to be installed in the ‘down’ position only.

Another minor comment regarding the flaps: their fit is tight against the wing and the fuselage. I recommend you to dry-fit and evaluate if you need to file/sand down a bit the positioning pin of the aileron to the fuselage.

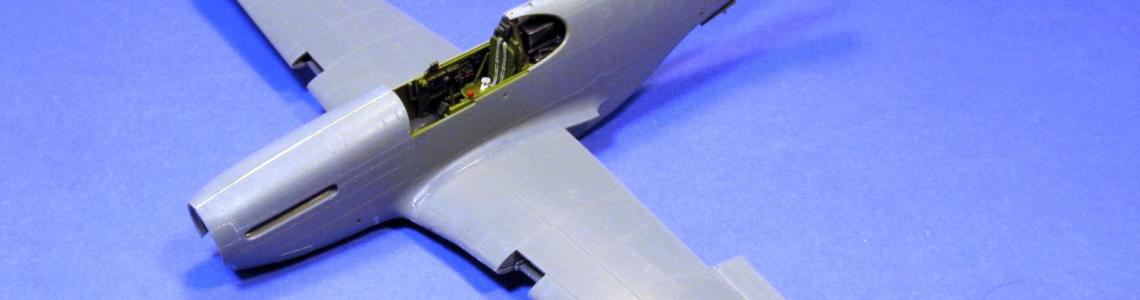

Mounting the fuselage to the wing was very easy and the fit was excellent. Assembling the tail surfaces and rudder was also a straightforward affair and the model was then getting ready to be inspected for painting.

I did have a few seams to work through, mainly along the nose and the radiator scoop in the belly of the model. After taking care of the seams using Perfect Plastic putty, I had a model ready for priming and painting.

I used One-Shot Ammo-By-Mig primer and Tru-Color acrylic paints, as they are fast-drying and allowed me to get the whole paint job completed in 3 evenings. I chose to go with the markings of the 357th FG because I always liked the red/yellow checkerboard in the nose. Eduard provides the model with D-Day invasion bands but instead I choose to finish the model without them.

After applying a gloss coat (Future) and let it cure for a full weekend, I applied the decals. They responded well to the MicroSet/Sol combo, sitting down in all the panel lines and crevices. The only decal I had a hard time conforming to the model curves was the red/yellow checkerboard in the nose. It looks OK but it is not as good as I wish I could have got it. If I were to do it a second time, I would paint the yellow background and then with a lot of patience, trim each red square and apply each one by one. It will take time but most likely will look better than the decal.

These are the “new” Eduard decals (now standard for the last few years) which let you remove the carrier film after application. I had a good experience - for the most part - removing the carrier film but in a handful of spots the actual decal lifted as well, leaving a small spot of the painted plastic exposed. I guess you can call it “weathering”.

As an experiment, I did not remove the carrier film in all the decals as I wanted to see if it is possible to tell the difference between having or not having the carrier film removed. For instance, the nose decals (Shanty Irish) have the carrier film while the kill markings (just next to them) have the carrier film removed. Truly, I cannot tell the difference once the model was finished. That speaks of the quality of the decals themselves that the carrier film cannot be seen when properly applied.

My personal recommendation is that if you are doing a natural metal finish aircraft you probably want to consider removing the carrier film. But if you are making a camouflaged bird, you can leave the carrier in place, assuming you have a nice shinny gloss coat to apply the decals to. The carrier film will be indistinguishable from the surrounding area under the second gloss coat and final flat coat.

I was now moving towards the final steps, i.e. landing gear, masts, etc. Assembling the landing gear was relatively simple but ensuring alignment was not. When I look at the landing gear, I think it is canted forward but that was the position where the landing gear wanted to sit in the wheel well. I don’t know what the problem is and because I didn’t think of dry-fitting the landing gear in the wheel bay (during assembling), I am now paying the price for skipping that check.

After a final flat coat and removing the masks for the canopy, the model was almost completed. The remaining part was to install the red/green navigation lights on top and bottom of each wingtip. That turned out to be one of the most challenging parts of the whole build. The parts are so minuscule that I lost 4 of them (Eduard provides you with 6, you only need 4). If you look carefully to the pictures, you will notice there are wingtip navigation lights on the upper surfaces only. The ones for the lower surfaces are somewhere in my basement, probably never to be found again. Including with all the spares as well.

After having built the model, I would the tight tolerances of the molds mean you must clean all parts from sprue ‘nubs’ and dry-fit them before committing to glue. There are lots of small parts that require tweezers and magnification, so be prepared to work your way through the model. But that is a low price to pay considering the overall quality and level of detail of the model.

If you have built several models and have experience with small parts and photoetch, I recommend you buy and build this model. You will have no trouble with it (perhaps only handling some of the smallest parts might be difficult).

I have built P-51Bs (from other manufacturers) that are extremely nice kits, however in my opinion this is the best P-51B in the market at time of writing the review.

Highly recommended.

I would like to thank Eduard and IPMS/USA for the review model.

Comments

P-51B Review

Thank you for sharing a great looking Mustang and a list of suggestions that will be invaluable during the construction of this kit. Nicely executed.

Eduard P-51

Hi Tomasz:

Thanks for the comments

IPMS

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews