P-40E Warhawk Royal Class Dual Combo

Late last year I asked Santa to pre-order Eduard’s P-40E Warhawk Royal Class Dual Combo kit for me. Eduard’s new 1/48th P-40 is the first newly tooled P-40E that I’m aware of since Hasegawa’s 2005 kit. The Hasegawa kit is pretty good, but there were some engineering choices that made it less fun to build than it could have been. I’m surprised that it has taken 20 years for another manufacturer to get around to kitting such an iconic aircraft. Airfix’s 2016 kit is of the earlier Tomahawk/P-40B version.

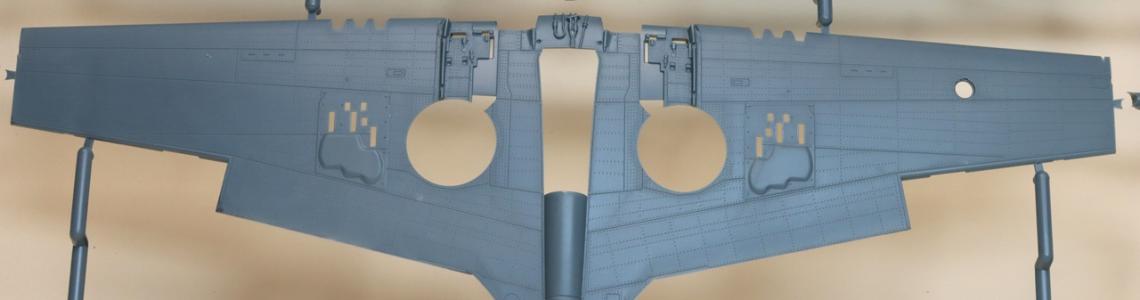

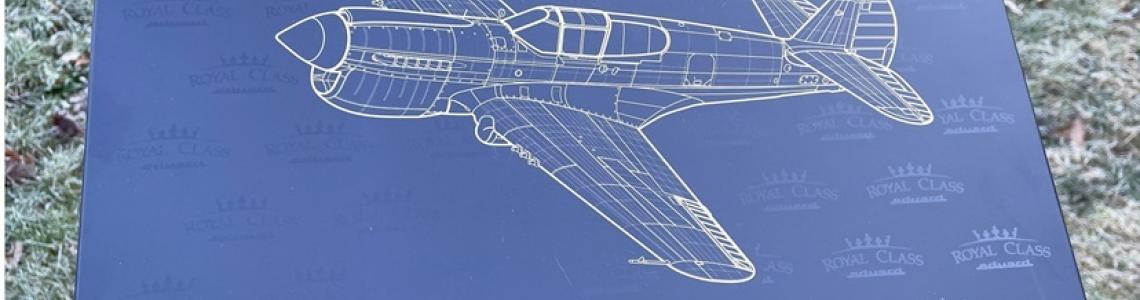

The Royal Class boxings from Eduard are limited edition kits that usually come with extra goodies that won’t be available in later boxings of the kit. Mine came with a very nice print of Aleutian Warhawks by Adam Tooby and a refrigerator magnet. Since this boxing is a “Dual-Combo”, it comes with all the parts, masks, and decals needed to build two complete models. Each kit comes with five trees of dark gray plastic and one tree of clear parts. The parts are very crisply molded with very fine surface detail. The exterior parts have very fine recessed rivets. Unlike the Hasegawa kit of twenty years ago, the fuselage sides are simple left and right halves (no modular inserts and separate tails for different versions). I am very impressed with how far around the curve of the fuselage the rivets go without fading or elongating. The fabric surfaces have fine raised rib tapes with no sags or scalloping effect between the ribs. The control surfaces are separate parts. The landing flaps are molded in the closed position. The clear parts are thin and have no distortions. A neat feature of the clear parts is that they extend past the edges of the areas that are clear on the full-size plane. This makes it easier to attach the parts and blend the seams without damaging the areas that need to be clear.

Two sets of pre-cut paper masks are provided for the canopy, wheel hubs, and landing light. The instructions for the masks are printed with a strange distortion, but the masks themselves look fine. These masks worked well and left no residue when removed. A set of soft foam masks are provided for masking the wheel bays.

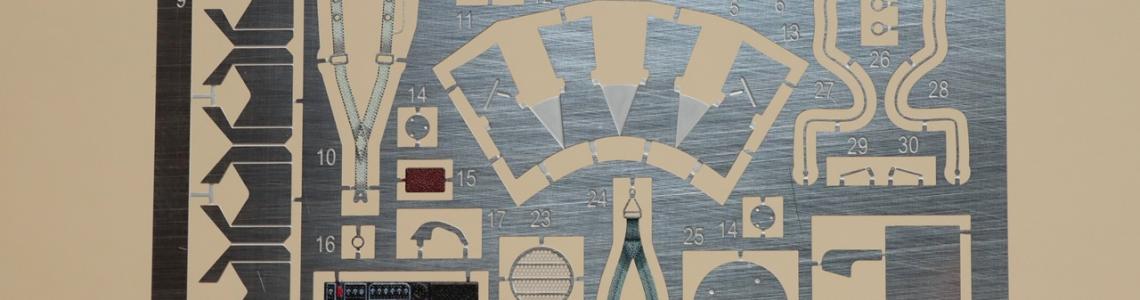

This “Royal Class” boxing comes with two frets of photo-etch and 3D-printed resin parts for the seats, wheels, and exhaust manifolds and pipes. I don’t know if the 3D-printed parts included in this kit will come in later Eduard boxings. You may have to buy them separately as “Brassin” upgrades.

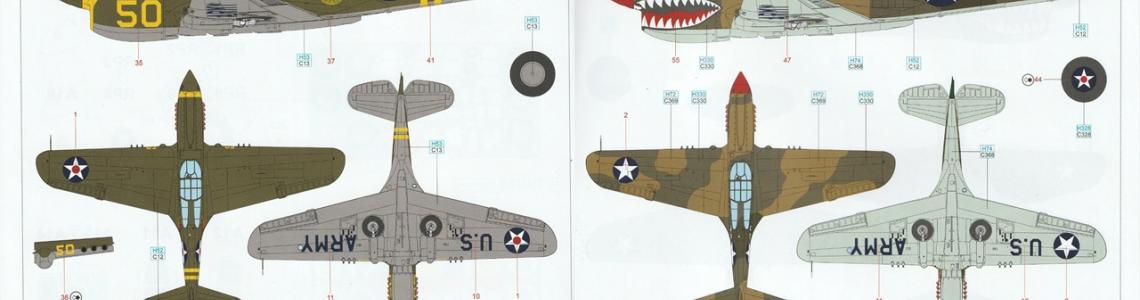

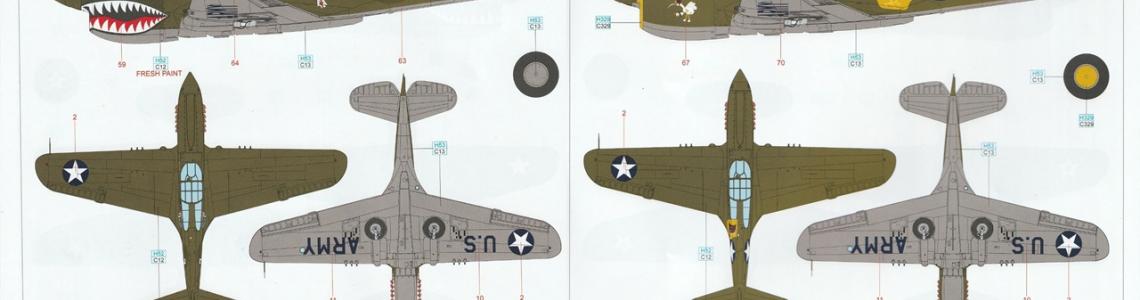

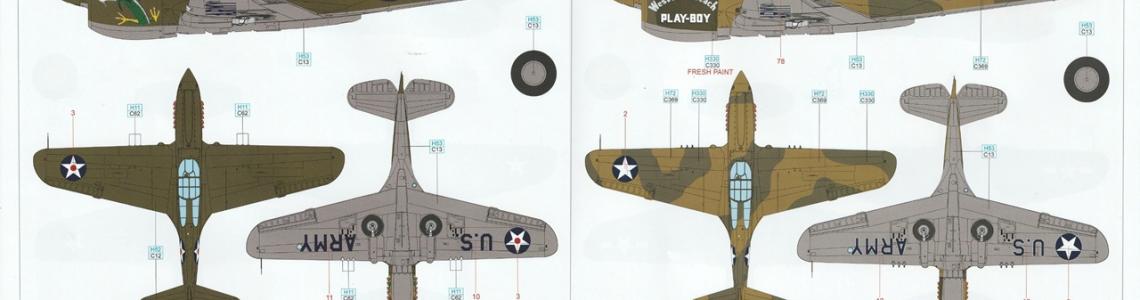

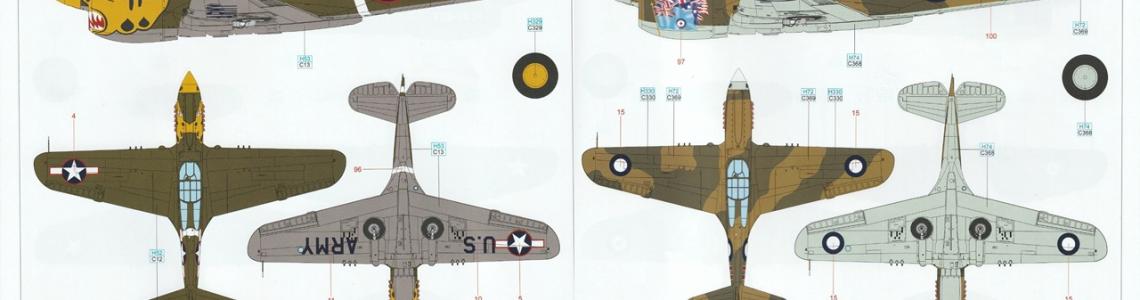

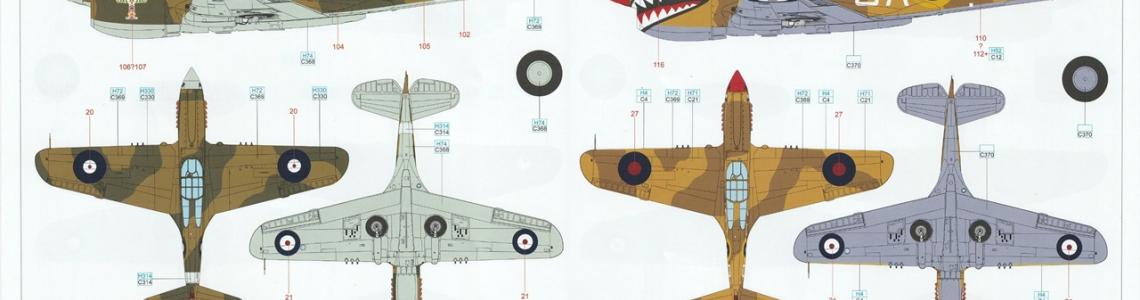

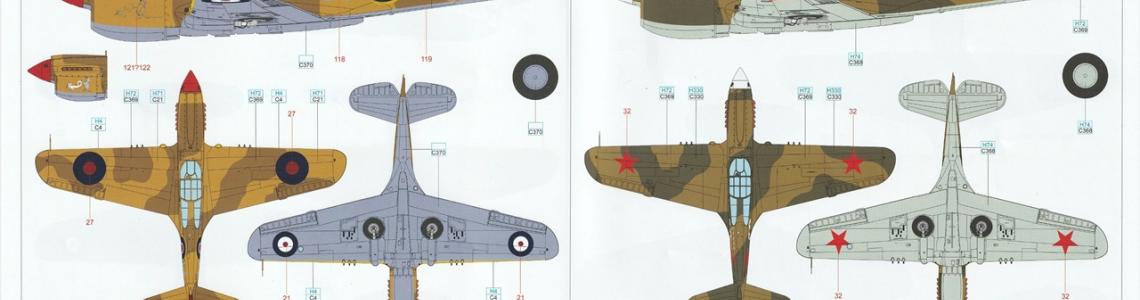

There are twelve marking options in this boxing. Seven are USAAC Warhawks, one stateside plane, two in the China-Burma-India theater, three from the South Pacific, and one from Alaska. There are two Royal Australia Air Force options. One from the South Pacific and one from North Africa. There is one Royal Canadian Air Force Warhawk from Alaska, a Soviet option from the Eastern front, and an RAF 112 squadron Warhawk from North Africa.

The instructions are clearly illustrated and easy to follow. There are many optional parts depending on the marking option you select, so be careful to keep track of which version you are building. Color call outs are listed for Gunze Mr. Color and Aqueous paints.

Not surprisingly, construction begins with the cockpit. The two optional 3D-printed seats (one with an American harness and one with an English harness) have very nice detail and natural-looking harnesses. The plastic seat parts are reasonably well-detailed, and there are both American and English-style harnesses on the photo-etch fret. The printing supports are all on the bottom of the seats and can be left on to serve as a painting handle. Under magnification, there are faint printing lines visible on the seats. I can’t see them without magnification, but I’m almost sixty. You may want to sand them. There is a mistake in the instructions regarding the installation of the seats. The plastic seat support (part D12) is only needed for the plastic seat or the resin seat with the British-style harness (RP11). The resin seat with the American-style harness has the seat support molded into the seat.

A great example of the attention to detail in this kit is that two different cooling flap levers are provided so that you can pick the one that matches the position of the cooling flaps you choose. The modeler has the option of using pre-colored photo-etch for the instrument panel or applying instrument decals to a panel with raised detail. The instrument panels include details for the backs of the instruments. There are four different gunsights molded in clear plastic. Three of the four gunsights have the reflector glass molded with the gunsight. If you use gunsight A9, you need to make your own reflector from clear scrap plastic. Cockpit placards are provided as decals, excess carrier film complicates getting them placed in tight spaces. I trimmed the film to make placement easier. The locating pins for the instrument panel are designed so that the rudder pedals need to be installed after the panel is glued to the cockpit sides. The fit of the cockpit rear bulkhead to the fuselage is impressive. This is frequently a troublesome area in P-40 kits. It is quite a relief not to have to touch up painted parts after trying to hide a seam.

A distinctive feature of P-40 is the nose with the big intakes for cooling air. Eduard has engineered this area so that the interior ducting meets the chin openings smoothly without steps (a drawback of the Hasegawa kit). Photo-etch is provided for the radiator faces but the plastic parts are so well molded I didn’t bother to use them. There are optional plastic parts for depicting the cooling flaps open or closed. The photo-etch fret includes flaps and actuator parts for building open flaps. The photo-etch cooling flaps are made so that folding them results in an exterior surface that has no edge between the inner and outer flap panels. I’ve noticed that on the Eduard website there is a new P-40E photo-etch set available that seems to have redesigned cooling flaps (PACIFIC STAR PE-set 1/48 11185-LEPT). I assume that this new set fixes this error. The plastic parts are quite good, so I used those instead. If you do use the plastic parts, do not cut off the actuator rods from part E2

There are 3D-printed parts for the cylinder head fairing and exhaust pipes. These parts are well detailed, and the ends of the exhaust pipes are hollow. The plastic versions of these parts are also very good, but the ends of the exhaust pipes are solid. Be careful installing the cylinder head parts (RP16 and RP17), as it is possible to make them fit upside down.

P-40s left the factory with fabric liners inside the landing gear bays. This Eduard kit has the option of building the main gear bays with canvas liners installed or with the metal structure showing.

I had trouble getting the landing light (A18) to sit flush with the lower surface of the wing. I trimmed away the lip around the mounting hole to get it to fit. This is a lot easier to do before the wing halves are glued together. There are various tiny clear lights to install after painting. These lights are very easy to lose, Eduard kindly provides duplicates of these lights.

Photo-etch is provided for the elevator trim tab actuators, but only for the upper surface. An antenna mast is included in the kit but none of the marking options use it. It is not mentioned in the instructions, but if you don’t use the antenna mast, you will need to fill in its mounting hole. The pitot tube is very fragile. Wait until the end of the build to install it. There is also a British-style pitot included, but none of the marking options uses it.

There are two sets of resin tires and wheels. One with block tread and one with diamond tread. They have very nice detail, and the logos and tire data are legible on the sidewalls. The wheel spokes are separate 3D-printed parts, and the wheel covers are photo-etch pieces. The wheel covers should be slightly convex. I used a ball-ended sculpting tool to work a dish shape into the photo-etch. Since all the marking options use the wheel covers, these wheels seem unnecessarily complex. I would have preferred the wheel covers molded into the resin. I assume that the spoke detail is for later variants of the P-40. The plastic parts for the wheel hubs are very good. The kit has plastic parts for smooth tread tires. There are some plastic diamond tread tires, but they are marked “not for use”. They may be for a later variant and might not fit the P-40E wheels. I found that I needed to deepen the holes on the resin wheels slightly to avoid too large a gap between the tires and gear legs. Photo-etch is provided for the brake lines. I used thin copper wire on my build because I felt that it would be easier to work with. The illustration on page 11 showing the installation of the wheel on the gear leg is incorrect. The brake line fitting should be at the top and forward of the gear leg when installed.

A few years ago, Eduard switched suppliers of their decals. At that time, there was some criticism of the printing quality of the new decals. The decals in this kit look better than the decals of that time. Registration and color uniformity look good to me. The carrier film on the stencil sheet seems very thin to me. The carrier film on the larger multi-colored marking looks thicker and slightly uneven. Several modelers over the past few years have discovered that the carrier film of Eduard decals can be removed after application, resulting in a very realistic painted-on appearance. I did some experimenting with the various methods I’ve seen for removing the carrier film. Pulling up the carrier film with tape is as likely to rip up the whole decal as it is the carrier film. I tried using a wet paintbrush to lift the edge of the film and gradually peel it off. This works fairly well but frequently tears the decal in places where adhesion is incomplete such as over panel lines and rivets. I had the best results by applying the decal with Mr. Mark Setter, pressing out the liquid and pressing the decal into the details, and then letting the decal cure thoroughly overnight. I then brushed mineral spirits over the decal. After letting the mineral spirits work for about a minute, the carrier film can be rubbed off with a cotton bud. If you use this method, you will need to make sure that your paint is resistant to mineral spirits and is thoroughly cured. These decals didn’t seem to respond much to softening solutions such as Micro-Sol or Mr. Mark Softener, either before or after removing the carrier film. I found that in many places I had to physically press the decals down into the rivet details. On a few larger decals, I tried sanding the carrier film with a 6000-grit sanding sponge before application. This flattened the carrier film and made it slightly easier to remove. The sanded decals also seemed to conform slightly better to surface details like recessed rivets. The carrier film on the stencils is too thin, and the decals are too small to sand before application. Many of them broke up when I tried it.

I also tried applying the Eduard decals normally without removing the carrier film. After the decals have cured thoroughly and a varnish is applied on top, the carrier film isn’t invisible, but it’s not super obvious either. The unevenness of the film visible while the decals are on the backing sheet seem to disappear after application. Many modelers will probably be content to use the decals as-is, without the extra work of removing the carrier film. If you haven’t used the new Eduard decals before, try some out on a test mule to see if and how you want to use them.

Overall, the fit of this kit is excellent and it is a very enjoyable build. With careful assembly, no filler will be needed. I am very impressed with the detail and quality of the molding. I also appreciate the engineering decisions that went into this kit. Although not a simple kit, nothing in this kit is difficult to get together correctly. I also appreciate that Eduard did not complicate the kit with modular assemblies to accommodate future versions, as Hasegawa did 20 years ago. This kit is without a doubt the best P-40 kit in this scale. Although this “Royal Class” boxing may be hard to get now, I’m sure that further Eduard P-40E releases will be fun builds too. I’m also looking forward to Eduard’s pending P-40N release.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews