North American P-51D Mustang, Part 2

At the time of this writing, it’s been a week since I penned the “First Look” at this amazing kit, and I’ve now logged 19 hours of benchtime on this baby – 19 glorious hours of relatively problem-free building with exquisitely-engineered parts and crystal clear instructions.

Powerplant

Virtually identical to the Spitfire Merlin, with the exception of several parts unique to the Mustang, the engine’s 80-plus parts all but “fell together” with about 3 hours of steady effort. Detail is crisp and accurate, fit is perfect, and it paints up into a real gem. Only disappointment here is the absence of spark plug wiring – which would be an easy add on another fret of PE.

Cockpit

Not sure what the aftermarket guys are going to do regarding aftermarket cockpits for this fella, since Tamiya absolutely nails quantity and quality of detail. Over 1/3 of build time thus far has gone into this pony’s office – clocking in at a hefty 7 hours.

The instrument panel is a 3-layer sandwich of faceplate with outstanding bezel and switch detail, a clear middle with instrument lenses, and a decal for the backside to provide instrument faces. Too bad it can’t be easily seen underneath the perfectly proportioned coaming, gunsight, and bulletproof front glass.

Floorboard, stick, console, and side panel is spot-on accurate and crisply and proportionally detailed. It paints up well, lending itself nicely to preshading, drybrushing, and sludge washes. Similarly the seat, with its PE belts and harness, is true-to-reference, although the chute pack is rarely seen in reference photos. Accurate radio gear and battery, atop the fuselage fuel cell, round out the detail behind the pilot’s seat and armor plate.

Radiator

Before the fuselage could be buttoned up, an hour was invested in building up and painting the radiator and oil cooler assembly. Nice touch, and all, with positionable radiator and oil cooler cowling flaps and some nice PE grilles inside. Again, a shame it’s so stinkin’ hard to see on the finished model.

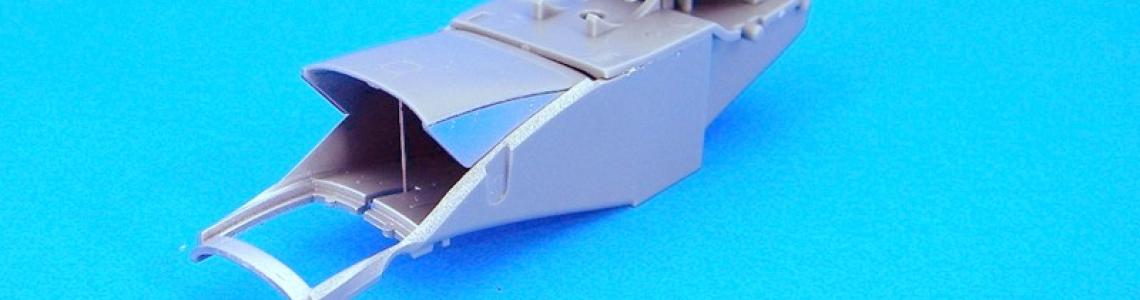

Fuselage

Once the Merlin, cockpit, and radiator were done, the initial cockpit and rudder assembly took about an hour to get everything put together – with a large chunk of that time invested in fiddling with the little metal rod and PE pieces for the rudder hinge. Again, on all counts, superb fit. I doubt I’ll need any putty here.

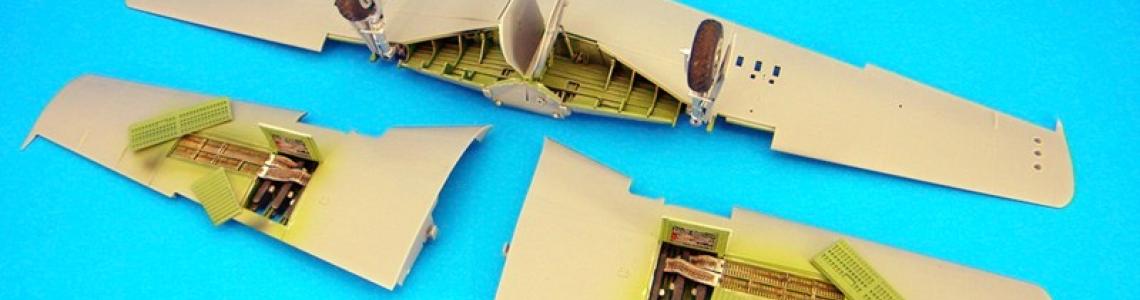

Armament

With the fuselage buttoned up, attention turned towards the business-end of this thoroughbred – the 6 .50 caliber machine guns. Again, parts are well-molded and have sharp detail, and excellent fit. The main ammo tray has nice depth of detail definition, making the rounds and belts easy to paint, drybrush, and sludge wash. The belts from the trays to the guns, although finely molded, lack the depth of detail and posed more of a challenge to paint to the same degree of crispness as the trays. Instead of dwelling here to improve, I decided to move forward – that dang deadline from the Reviewer Corps Commandant looming over my head. All said, about 4 hours were invested in building up the armament.

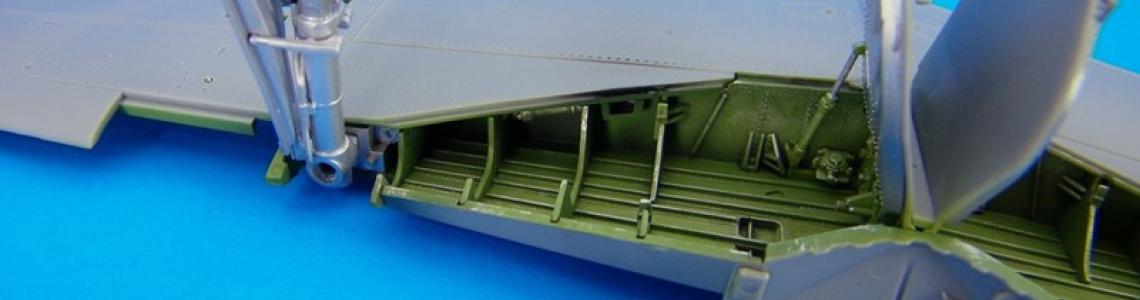

Landing Gear and Wheel Wells

The final subassembly of significance is the landing gear and wheel wells. Again, no surprises here – just perfect fit and great detail. A combined 3 hours were spent on these subassemblies.

Struts are reinforced with metal rods, and screw into the trunion mounts, and are capped by leading edge sections with embedded magnets which align with the ferrous strut screws. As with the Spitfire, the landing gear can be removed and replaced with duplicate parts in the “gear-up” configuration. Brake lines are finely molded and fit to a tee. Inboard and outboard gear doors are each multi-piece assemblies, with the outboard doors capturing the strut mounting bracket. Door depth and detail is excellent. Tires are molded rubber, and scuff up nicely while removing the mold parting line. Wheel hubs are so finely molded that even the valve stems are captured.

The wheel well is packed with structural detail, along with some hydraulic lines and other miscellaneous hardware. Inboard gear door and strut assemblies snuggle right into their intended places. Only disappointment here was those pesky tiny ejector pin marks -- very touchy to remove amidst the fine detail. To Tamiya’s credit, they did try to locate them beneath and behind other parts.

Summary

With roughly 60% of the applicable steps completed, this Mustang is by far the best this review has ever seen – no others even come close. Lots of parts – lots of detail – lots of trouble-free work – lots of modeling value for the buck. Looking forward to getting it all buttoned-up and giving it some color. No doubt the expectations for the remainder of build are extremely high!

Again, sincere thanks to the good folks at Tamiya USA for providing this sample kit and to the IPMS Reviewer Corps Commandant for entrusting me with the build and review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews