LAV300 90mm Cockerill Gun

The LAV-300 (Light Armored Vehicle-300) is a 6x6 wheeled armored vehicle developed in the 1970s by Cadillac Gage, an American defense contractor, as part of their V-series of vehicles. Originally known as the V-300, it was designed for reconnaissance, troop transport, and other battlefield roles. It could be equipped with various weapon systems, such as machine guns, auto-cannons, and anti-tank guided missiles, enabling it to operate effectively in various combat scenarios.

With a crew of three, commander, driver, gunner, and a troop seating capacity of ten, the LAV-300 was powered by a Cummins 6-cylinder diesel engine, enabling it to reach a top speed of 65 mph on roads and 1.9 mph in water. Water propulsion is provided by water jets mounted on either side at the rear. Armament included a 90mm CMI Defense Mk III gun (Cockerill) and one 7.62mm machine gun. The Cockerill 90 mm gun, developed in 1986 by the Belgian company John Cockerill, was designed for use in light armored vehicles, featuring a high-velocity, low-recoil system.

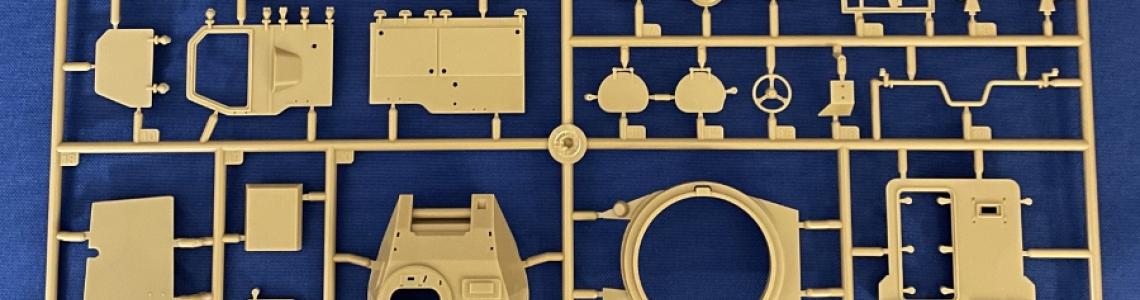

Hobby Boss's new tooling kit, released in 2024, includes over 290 parts, rubber tires, photo-etched components, and a copper cable.

Box and Contents

Measuring 15.5” x 8.25” x 3”, the box features a vibrant LAV300 90mm Cockerill Gun image in one of the two paintings/marking guide images.

- Sprue A x 1

- Sprue B x 2

- Sprue C x 1

- Sprue GP x 1 Clear Parts

- 1 Baggie Containing Rubber Tires x 6

- 1 Small Decal Sheet for two vehicle versions

- 1 Baggie containing photo-etch x 2 and 1 copper cable

- 1 Information Sheet

- 1 12-page portrait-style instruction booklet covering 46 steps

- 1 Paintings and Markings Guide

The Build

The build is divided into three sections: Steps 1-15 covers the suspension, Steps 16-39 focus on the upper hull, and Steps 40-46 deal with the turret.

Steps 1-4: The construction begins with the suspension assembly, featuring a swing-mounted solid front axle, two rear independent suspension assemblies, and coil springs at each wheel. The solid front axle is secured longitudinally by trailing arms and stabilized laterally by rods connecting the axle to the hull. The two rear axles feature short drive shafts extending from the hull-mounted differentials to the wheel stations, which are mounted on independently sprung trailing arms. All the parts are well-detailed, and the fit is excellent. The molded coil springs require minimal cleanup. Additional parts included the attachment brackets (parts B24 and B25) for the water jet thrusters.

Steps 5-9: These steps complete the lower hull assembly by building the jet water thrusters with photo-etch grill plates and attaching the coil springs, axle dampers, and shock absorbers.

Steps 10-15: The first construction phase is completed by assembling the six wheels with rubber tires and attaching the front plate. The wheel detailing is exceptional, closely matching reference photos. The instructions in steps 11-14 advise builders to pay close attention to the direction in which the rubber tires are attached to the wheels. I left the tires off until the painting was finished. Additionally, note that the tires have a seam that needs to be sanded off.

Steps 16-18 & 23: In these steps, construction progresses with interior details such as the steering wheel, fire extinguishers, seats, shift levers, a two-sided bench seat for the crew, an instrument console, and the addition of the rear doors with two vision ports. Step 23 finalizes the addition of details to the interior. After completing these steps, the interior was initially primed with Ammo Mig One Shot Grey 2024, followed by a light layer of Model Air White Grey 71.119. The interior details were then painted using various acrylic paints, followed by applying decals to the consoles (B37, C1) using Micro Sol and Micro Set.

Steps 19-39: These steps involve the upper hull details with the addition of driver hatch covers with grab handles, engine deck covers, vision ports, jersey cans, and other small parts. Although the hatch covers can be left open, there is no underside detail unless scratch-built. Once again, an instrument (part C67) is mounted on the roof of the upper hull and includes a decal. Step 27 requires bending the photo-etch for the cable, but the instructions do not provide detailed guidance. For accuracy, consult a reference picture or view the completed model on Hobby Boss’s website. In Step 28, the cable is assembled using parts C29 and B31. To achieve a metallic appearance, I soaked the cable in Birchwood Casey Super Blue Liquid, thoroughly rinsed it with warm water, and allowed it to dry. I then applied a wash using Vallejo Model Color Light Rust Wash 505. The cable eyelets and hooks were primed with A. Mig Black One Shot Primer, then a light coat of Vallejo Model Color German Black Brown 70-822.

Steps 40-46: These steps start with assembling the turret, which includes adding the 7.62 mm machine gun and the 90 mm Cockerill gun. The barrel for the Cockerill gun is a one-piece slide-molded part, and the hatches are also installed during this stage.The turret hatches can be positioned open in step 44, featuring latch handles on the inside. After painting the inside of the vision ports with Tamiya X-23 Clear Blue, the rear basket with photo-etch, turret light, and fuel caps are also installed at this stage. The 7.62 mm MG was first painted with A. Mig Gun Metal 045, followed by a wash using Vallejo Model Wash Black 76.518. Afterward, it was lightly brushed with A. Mig Gun Metal Pigment 3009.

Painting and Decals

The painting was conducted concurrently with each assembly process described in each step. I chose to follow the painting and marking guide number (I), using Vallejo Model Color US Dark Green 70.893, Ammo Mig Flat Black 046, and Vallejo Model Color Neutral Gray 70.992. After these coats were allowed to dry for 24 hours, I applied a gloss clear coat using Model Master 6380 to prepare for the application of the decals.

The decals were applied using Micro Set, resulting in no silvering. Hobby Boss’s decals are consistently user-friendly and easy to apply. The soaking-to-application time is shorter than with most decals. I discovered that a 10-second dip in water was the ideal time frame. After allowing the decals to sit for 24 hours, I applied a protective coat using Model Master Semi-Gloss Clear.

References Used

- https://www.behance.net/gallery/57396497/CADILLAC-GAGE-LAV-300

- https://www.toadmanstankpictures.com/v300.htm

- https://web.archive.org/web/20061124112247/https://www.textronsystems.com/pdf/products/lav300_datasheet.pdf

In Conclusion

Those familiar with assembling Hobby Boss model kits will appreciate their impressive level of detail. Additionally, the low parts count makes this kit an enjoyable build. One item I never noticed before was that Hobby Boss tapes the protective film onto the decal sheet. A nice touch. The only drawback I noticed was that some instructional details for parts placement were unclear. However, this would not stop anyone from enjoying the process of building the LAV-300 from Hobby Boss.

I highly recommend this kit.

Thanks to IPMS/USA and MRC for allowing me to review this kit.

Reviewer Bio

Phillip Cavender

Phil Cavender, IPMS/USA #50085, is a retired pharmacist from the Veterans Administration, having retired in 2011. While he explored model car building as a child, it wasn’t until 2015 that he rediscovered plastic scale modeling. His renewed interest emerged while researching his father’s military history, which led him to a local hobby shop. There, he met a former UK military tanker who reignited his passion for the hobby. After relocating to Myrtle Beach, Phil teamed up with six skilled modelers to co-found the Grand Strand Scale Modelers chapter of IPMS/USA. He now focuses on building armor models in scales from 1/35th to 1/16th.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews