Fokker D.VII (Fok) - Part 1

The Subject

The Fokker D.VII is one of the most recognized fighters of the Great War and has been chronicled so many times that it is unnecessary to spend a great deal of time describing it to this audience. Suffice it to say the legendary fighter was (and still is) widely considered to be the best German fighter aircraft of WWI. Almost 3,300 Fokker D.VIIs were built by three manufacturers (Fokker, Albatros & OAW) in the last year of the conflict and they were often the reason a number of German pilots achieved ‘Ace’ status. Before building any model of this iconic aircraft, I would encourage modelers to seek out and read some of the history of the Fokker D.VII to more fully appreciate the experience.

The Kit

Wingnut Wings has produced four versions of the Fokker D.VII. This kit assembles into the Fokker-built version that was equipped with the Mercedes D.IIIaü in-line engine. As most model builders know, Wingnut Wings raised the bar for plastic model kits a couple of years ago and their kits have become a veritable benchmark that other WWI aircraft kits are measured against. Everything about Wingnut Wings kits is top drawer…and, this kit is no exception. It is about as good as it gets.

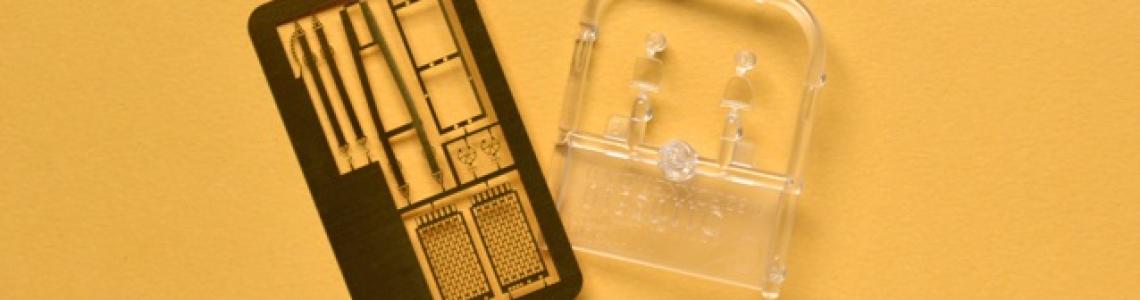

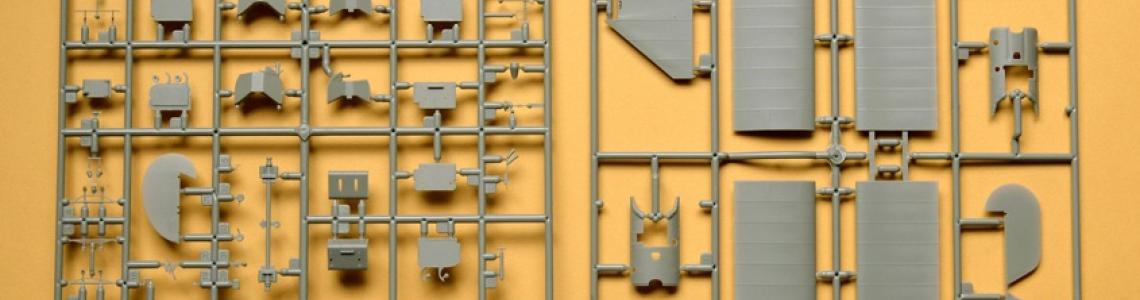

The kit instruction book says there are 198 gray injection-molded parts, but I counted 205 on the eight sprues in the kit. See the photos below. The sprues are actually identical to those in Wingnut Wings’ other (Fokker, Albatros, OAW) Fokker D.VII kits. Parts for all versions are included so there will be a few parts left over after a Fokker-built version is completed (maybe that’s how they arrived at the 198 parts count). The instruction book calls out the parts that are required, so it is important to carefully follow each step as some of the detail differences are subtle. There are 2 clear parts (windscreen options) on an additional small sprue, a fret of eight photo-etched parts and six large sheets of Cartograf decals that provide markings for five aircraft. The vividly printed decals provide full lozenge patterns (2 versions) and all markings for the following aircraft.

- Fokker D.VII 234/18, Fredrich ‘Fritz’ Fredrichs, Jasta 10, March-April 1918 (with 21 victories)

- Fokker D.VII 286/18, Willi Gabriel, Jasta 11, June 1918 (with 11 Victories)

- Fokker D.VII 368/18, Hans Schultz, Jasta 18, June 1918 (with 1 victory)

- Fokker D.VII 4301/18, Fritz Oppenhorst, Jasta 71, August-November 1918 (with 2 victories)

- Fokker D.VII, Gotthard Sachsenberg, MFJGr 1, October 1918 (with 31 Victories)

Everything in the kit is separately bagged. As is typical of all WNW kits, the injection-molded parts are beautifully cast, exquisitely detailed, with practically no flash and feature strategically placed ejector pin marks that should cause no concern during assembly. Parts breakdown is easy to follow and assembly is guided in a logical sequence that makes building a WWI biplane a peasant experience. Parts fit is well engineered and nearly foolproof if care is exercised to fully remove sprue attachment stubs on parts and components are fitted without overstressing anything. Take note that the alignment pins and corresponding mounting holes are quite petite but sufficient if they are kept free of paint (something I may be repeating along the way). As I noted in a previous review of the Fokker D.VII F kit, to simplify assembly and ensure correct alignment, each of the main three-legged cabane struts is molded in once piece and, in the case of the struts, there are substantial locating tabs on the tops of the to assure a solid bond with the upper wing. The interplane struts are molded as single "N" shapes and have equally substantial locating pins that fit snugly into their respective holes in the wings (if there is no paint film in the slots).

The Build

The kit instructions recommend assembling the cockpit first. The assembly sequence is straightforward but most of it begins with instructions to paint all of the various interior components before assembly according to the color callouts provided on pages 4 thru 6. However, the photos of a restored Fokker D.VII on page 7 and the color illustrations on page 8 should be refereed to at this point to assure that all details are correctly painted. It will be difficult to add the color details to certain small details shown in the photos and color illustrations after they are attached to other parts. Because the accurately detailed cockpit will be a major focus of attention when the model is completed, painting all the details beg the modeler to take the time to render them as accurately as possible.

The step-by-step instructions for assembling the cockpit were followed with two exceptions. In the first assembly sequence, the instructions guide you to attach the pilot’s seat and seat brackets to the cockpit back wall frame then two steps later instructs you to install the photo-etched safety harness to the seat back. I believe it is easier (and wiser) to install the safety harness before the seat is attached to the back wall frame to avoid a likely fit problem and predictable glue smears on something. I annealed the photo-etched parts before attaching them so they could be worked into more relaxed positions. The other thing I would recommend is to attach the various control cables to the rudder bar and control column before they are attached to anything. An illustration on page 8 shows this, but it should be addressed at the beginning of the build, not when getting to page 8.

The instructions list the Tamiya, Humbrol and Misterkit paints that match the color callouts. I used Tamiya and Gunze Mr. Color because I prefer those paints and know both will airbrush smoothly in thin coats, cover well and dry quickly (And, it was not difficult to match Mr. Color paints to the specified colors). After pre-painting the appropriate base color on everything and applying a coat of Future, oil washes were applied and small details were hand brushed with Vallejo acrylics, using a 10/0 ‘spotter’ paintbrush and a few highlights were dry brushed. See the photos below.

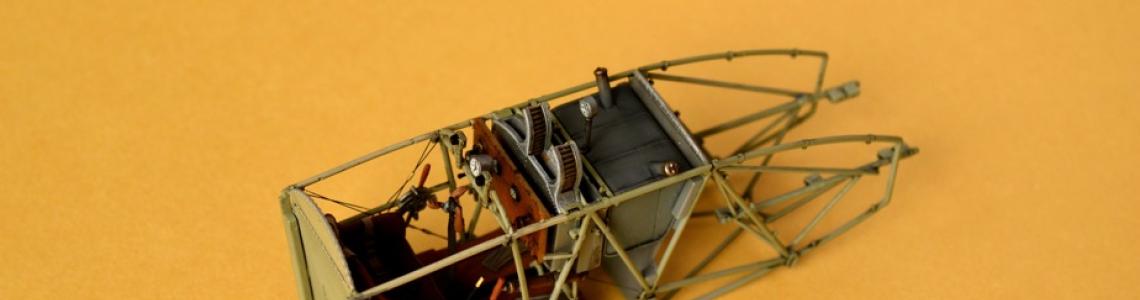

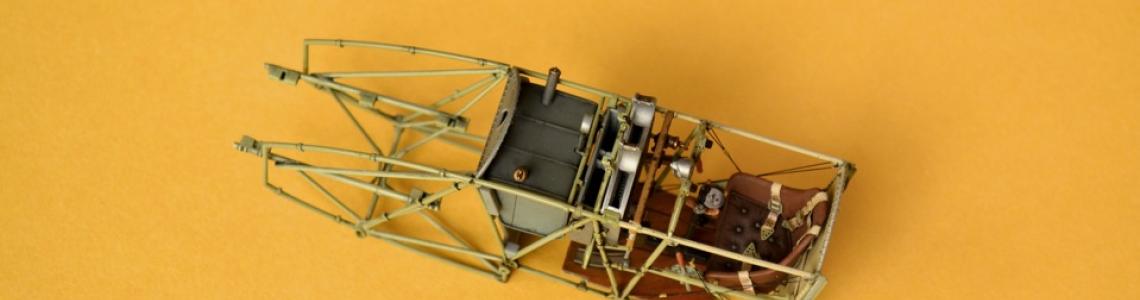

The various cockpit components were assembled into a unit and everything went together without a hitch (remembering, of course, that that attachment points of all parts in a WNW kit must be clear of paint). I found it helpful to frequently place the cockpit unit into one of the fuselage halves to verify that the frames and parts aligned with their respective details on the sidewalls. The frame members in the engine bay area were a bit fiddly, but did go together as the instructions show and aligned perfectly…if a little patience was exercised in fitting the petite pins completely into their respective mounting holes when cemented things together. It’s worth noting that if you find it necessary to force or clamp anything at this point, you probably are making a mistake. The internal rigging guide on page 8 clearly illustrates how the cables that were attached to the rudder bar and control column run through their respective openings below the seat after those parts were assembled. As the photos clearly show, the finished cockpit assembly is something of a model in itself. Unfortunately, some of that detail eventually will be difficult to see when everything is fully assembled.

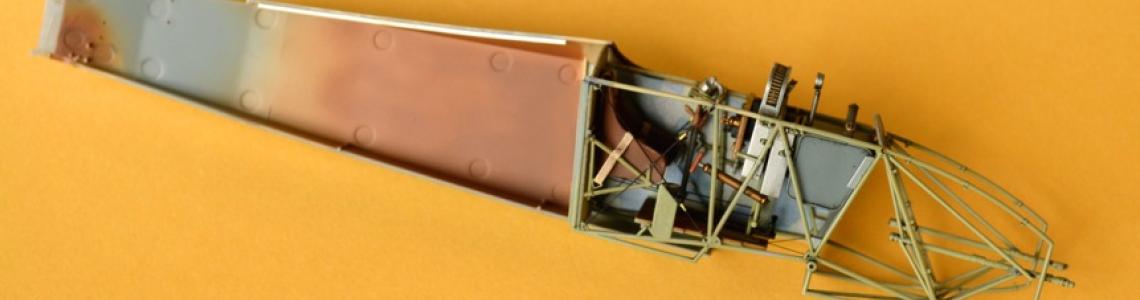

I may sound redundant, but the Mercedes D.IIIaü engine also builds into a model in itself. It could be placed on a set of saw horses next to the aircraft in a diorama to fully appreciate it, but most model builders will place it on the engine mounts and then cover up much of it with the engine cowlings.

Since the instructions guide prepainting most components before assembly, it’s important to keep in mind that, like everything else, the engine parts fit well if there’s no paint on attachment surfaces (remember, I said I would be repeating that). The engine as supplied is fully detailed, with one exception…well, maybe two. There are no ignition plugs on the cylinders. Instead, there are small raised rings in the appropriate locations that can be drilled out to install scratch built (or aftermarket) ignition plugs. After that, ignition wires can be fashioned and attached. I chose to drill out the holes, scratch build the plugs from stretched Evergreen styrene rod (because it is already white) and add ignition wires from copper wires that I chemically blacked with MicroMark’s ‘Blackin-it’. The photo below of the engine in place clearly shows the plugs and wires.

As I found in my earlier Fokker D.VII build, closing up the fuselage sides around the framing of the cockpit can be a bit of a task because of the high level of detail along the outside of the frame members and how precisely everything is intended to fit. When dry fitting the cockpit in place, I found that a light sanding of the outside edges of the frame members (which will never be seen when the fuselage is assembled) relieved enough of the resistance to permit everything to close up without a lot of clamping. Note the instructions clearly call out closing up the top seam first and drawing the bottom edges together after the top has set. It is an important instruction to heed. Since there are no alignment pins along the top seam, to avoid any chance of a seam line showing up later, I added a strip of Evergreen styrene to reinforce everything (note it can be seen in the photos below). At this point, I placed the engine in the engine bay to check how it fit but delayed cementing it firmly in place until later in the build when the cowl front is attached to assure alignment.

It’s time to move on to the wings and tail feathers. I’ll address that and conclude the build in part 2 of this review. However, I can say already this is a great kit, and a rewarding build. It is highly recommended. My thanks to Wingnut Wings for providing the review sample and IPMS/USA for allowing me to build and review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews