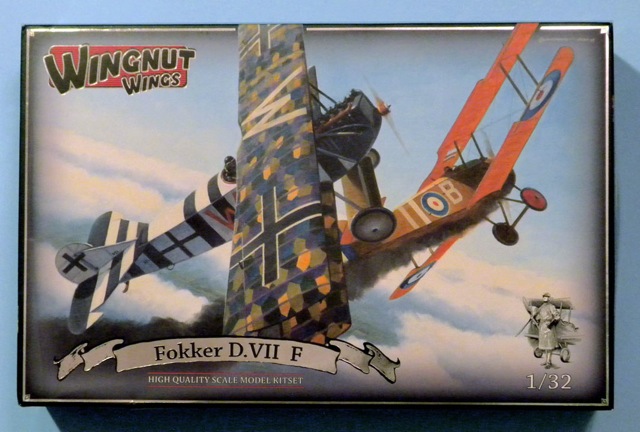

Fokker D.VII F - Part 1

The Aircraft

What hasn’t been said or printed about the Fokker D.VII? The legendary fighter is widely considered to be the best German fighter aircraft to emerge from the Great War and it was certainly the most numerous type engaged in the conflict. Nearly 3,300 Fokker D.VIIs were built by three manufacturers, (Fokker, Albatros & OAW) in the summer and autumn of 1918, and many of them were the reason a number of German pilots achieved ‘Ace’ status in the last year of the war.

From its introduction into service in May 1918, the Fokker D.VII quickly proved its vastly superior performance over most, if not all, existing Allied fighters. With a high rate of climb, higher service ceiling and outstanding handling characteristics, German pilots scored 565 victories during the month of August alone. Because of its impact, it was the only aircraft listed in the armistice terms that Germany was required to surrender to the Allies.

The Fokker D.VII originally was equipped with the Mercedes D.III in-line engine, but that soon was switched to the higher horsepower D.IIIaü. However, by the summer of 1918, Fokker began manufacturing a version that received a new engine from the BMW firm that provided an increase in speed and climb rate at higher altitude. That version of the aircraft, powered with the BMW IIIa ‘altitude’ engine, was designated the Fokker D.VII F. It is the subject of this kit from Wingnut Wings.

The Kit

The Fokker D.VII F is the fourth version of the iconic fighter that Wingnut Wings has kitted. And, what hasn’t been said or printed about Wingnut Wings kits? They’ve raised the bar so far for plastic model kits that their kits have become the benchmark that other WWI aircraft kits (and many others) are measured by. All of the accolades are well deserved. If you have not yet seen a Wingnut Wings kit, prepare yourself for a journey through near perfection when you first encounter one. As has been said many times before, everything about Wingnut Wings kits is top drawer…and, the Fokker D.VII F is further proof of that.

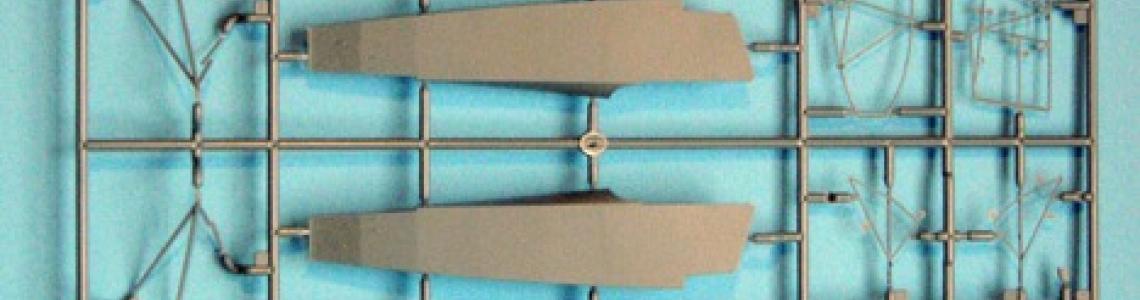

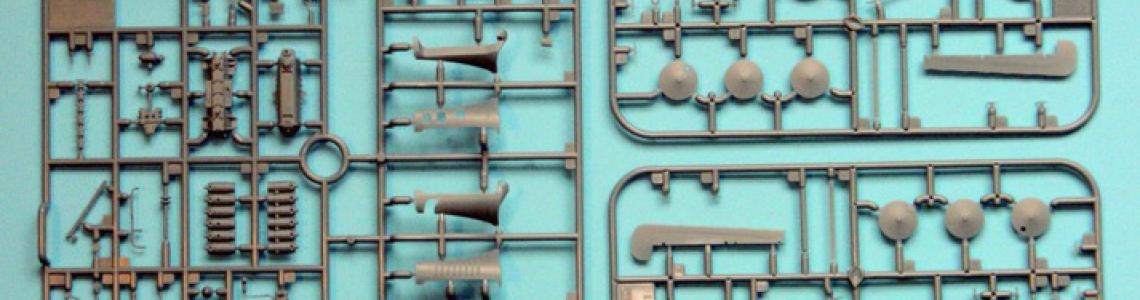

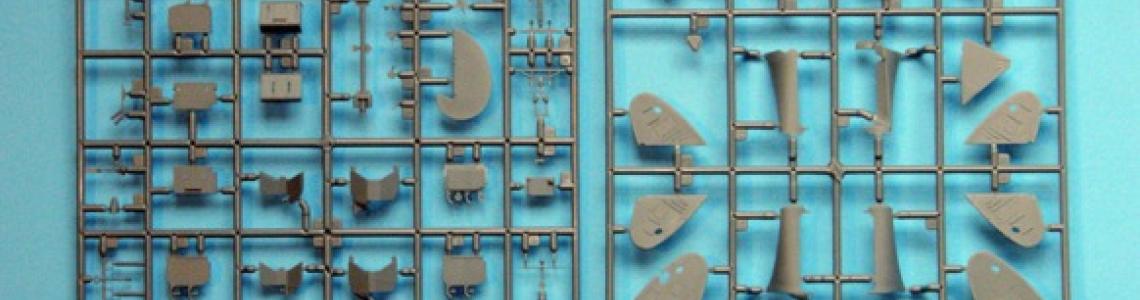

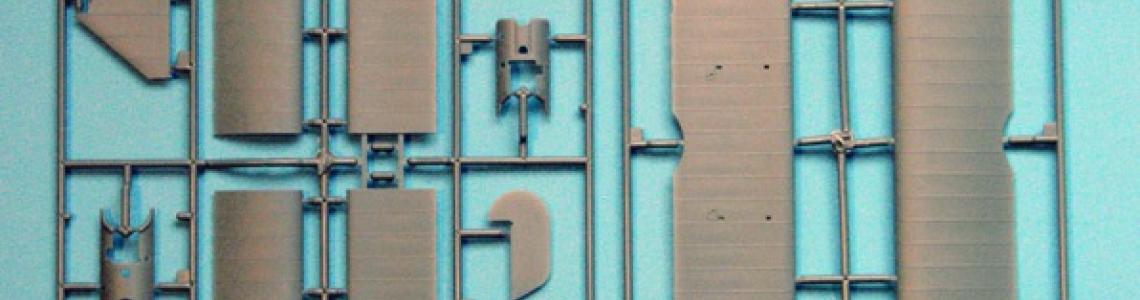

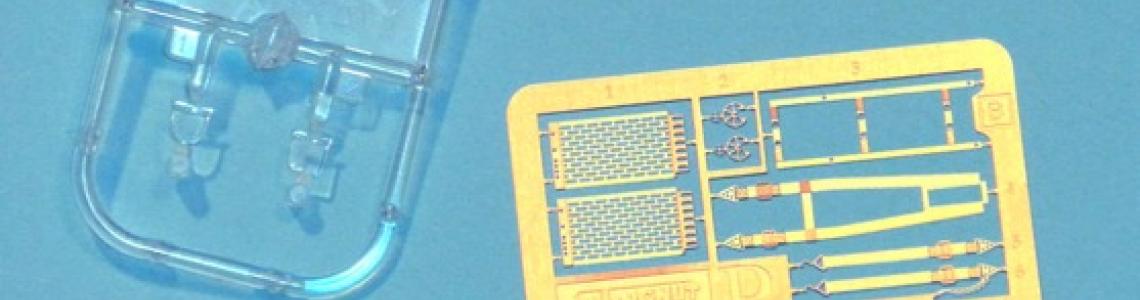

This kit contains 198 gray injection-molded parts on nine sprues. See the photos below. The sprues are actually identical to those in the previous (Fokker, Albatros, OAW) kits with the exception of Sprue E, which contains the parts to build the BMW IIIa engine. The instruction book lists 36 parts that are exclusive to the D.VII F…most consist of the engine and its cowling panels. There are 2 clear parts (windscreen options) on one sprue, a fret of eight photo-etched parts and three large sheets of Cartograf decals that provide markings for five aircraft.

The beautifully printed decals provide full lozenge patterns and all markings for the following aircraft.

- Fokker D.VII F 460/18, Eric Just, Jasta 11 August 1918 (6 victories)

- Fokker D.VII F 501/18, "Red W", Jasta 26, Noevmber 1918

- Fokker D.VII F 4253/18, Ernst Udet, Jasta 4, September 1918 (62 victories)

- Fokker D.VII F 4330/18, Egon Koepsch, Jasta 4, August 1918 (9 victories)

- Fokker D.VII F Karl Bolle, Jasta 2. November 1918 (36 victories)

Everything in the kit, including the 32-page instruction book, is separately bagged. As with all other WNW kits, the injection molded parts are beautifully cast, exquisitely detailed, with practically no flash and feature strategically placed ejector pin marks that should cause no concern during assembly. Parts breakdown is typical of most kits and assembly is guided in a logical sequence that should take most of the fear out of building a WWI biplane. To simplify assembly and ensure correct alignment, each of the main three-legged cabane struts is molded in once piece and there are substantial locating tabs on the tops of the struts to assure a solid bond with the upper wing. The interplane struts are molded as single "N" shapes and have equally substantial locating pins that fit snuggly into their respective holes in the wings. Added to this is the appeal of building a WWI aircraft that requires practically no rigging. I almost did a Snoop dance when I contemplated building this kit.

The Build (Part 1)

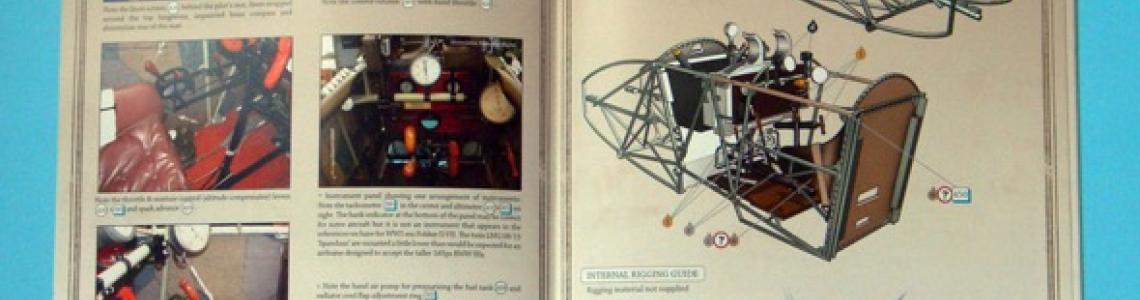

As with most kits, the Fokker D.VII F’s instruction book first guides assembling the cockpit. The assembly sequence is straightforward, but most of it begins with instructions to paint all of the various interior components before assembly according to the color callouts provided on pages 4 thru 6. However, I recommend that builders carefully study the photos of a restored Fokker D.VII F on page 7 and the color illustrations on page 8 to assure that all details are correctly painted before assembling anything. Take note that it will be difficult to add some color to certain small details after they are attached to other parts. Because there is much in the cockpit that will be the focus of attention, painting all the details will require some time and patience, but the results will be worth it.

I followed most of the step-by-step instructions carefully, but did deviate in a couple of instances. For example, in the first assembly sequence, the instructions guide you to attach the pilot’s seat and seat brackets to the cockpit back wall frame then two steps later instructs you to install the photo-etched safety harness to the seat back. I believe it is wiser to install the safety harness before the seat is attached to the back wall frame to avoid a predictable fit problem. I also chose to anneal the photo-etched parts before attaching then so they could be worked into more believable (read casual) positions.

The instructions list the paints available from Tamiya, Humbrol and Misterkit that match the color callouts. I used Tamiya and Gunze Mr. Color because I’m familiar with those paints and know both brands will airbrush smoothly in thin coats, cover well and dry quickly. It was not difficult to match Mr. Color paints to the specified colors. After pre-painting the appropriate base color on everything and applying a coat of Future, oil washes were applied and small details were hand brushed with Vallejo acrylics, using a 10/0 ‘spotter’ paintbrush.

There is a minor mistake in the cockpit assembly instructions on page 6. Take note that the instructions have the part numbers for the optional altimeter parts reversed. If you decide to include the altimeter and want to place it on the starboard side, use part #A33. If you want to position it on the port side, use part #A32.

The various cockpit components were assembled into a unit and I found everything went together without a hitch (remembering, of course, that that attachment points of all parts in a WNW kit must be clear of paint). It was helpful to frequently place the cockpit unit into one of the fuselage halves to verify that the frames and parts aligned with their respective grooves on the sidewall. An internal rigging guide is provided on page 8 that, again, should be considered much earlier in the assembly sequence. I recommend the cables be attached to the rudder bar and bottom of the control column before those parts are installed, then run through their respective openings below the seat after those parts are attached.

The finished cockpit assembly is most impressive…something of a model in itself as the photos below show. Unfortunately, some of that detail eventually will be difficult to see when everything is buttoned up (as shown in the photo below after the cockpit coaming was installed).

The frame members in the engine bay are a bit fiddly, but do go together as the instructions show if a little patience is exercised. After some dry fitting, I chose to lightly sand the outside of the frame members slightly to relieve the stress when the fuselage sides were brought together. Closing up the fuselage is made easier if the instructions in step 6 are followed. These instructions guide the builder to attach the two fuselage sides along the topside seam first. That is the preferred way to bring things together to avoid seam issues along the top. I clamped everything together while the cement dried to be sure there would be no hint of a seam. WNW provides a lacing strip insert to hide the seam along the bottom of the fuselage. It’s rather ingenious.

There is another small error to contend with when preparing the cockpit coaming. The instructions call for a color “t” to be applied to the inside of the coaming, but that color is not identified anywhere in the instructions or on the paint chart. I emailed WNW, asking what color “t” was. The response was that “t” should be “q”…so, I painted it dark green, just like the fuel tank.

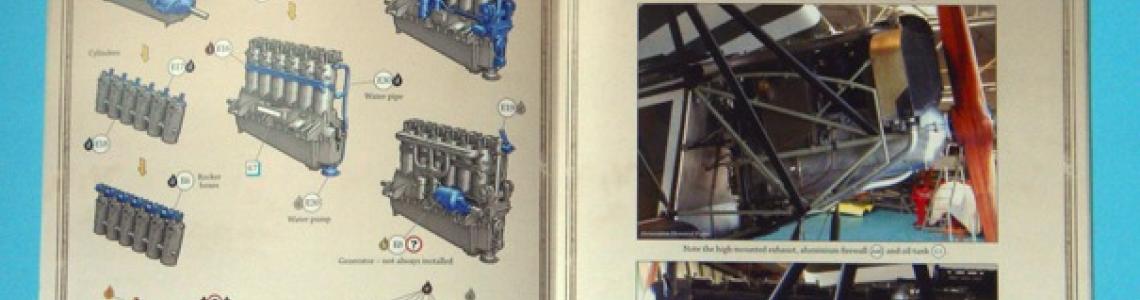

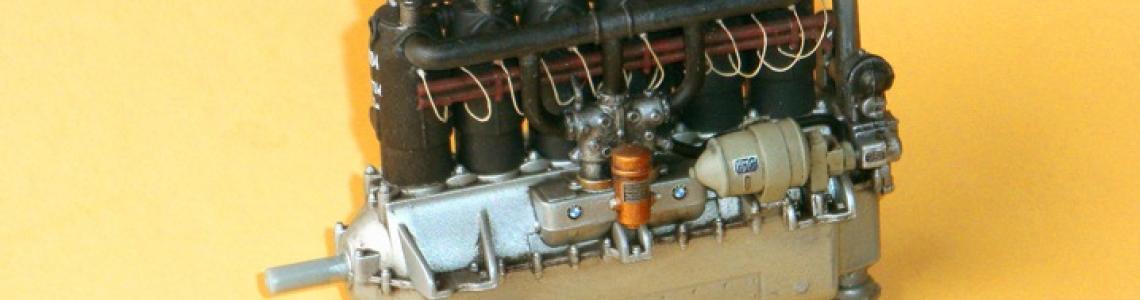

It may sound a little cliché, but the BMW IIIa engine also builds into a model in itself. It deserves to be placed on a set of saw horses next to the aircraft to fully appreciate it, but most model builders will place it on the engine mounts and cover up much of it with the engine cowlings. It’s important to keep in mind that parts fit well if there’s no paint on attachment points…again, tolerances are that tight. The completed engine is fully detailed, with one exception…well, maybe two. There are no ignition plugs on the cylinders. Instead, there are small raised rings in the appropriate locations that can be drilled out to install scratch built (or aftermarket) ignition plugs. After that, ignition wires can be fashioned and attached. I chose to scratch build the plugs from stretched sprue and add ignition wires for the review sample. See the photo below. Oh, there is one other small mistake in the instructions on page 11. The instructions incorrectly identify decal #78 for the starboard side of the engine block…it should be decal #68.

While waiting for assembled components to dry, I began to apply the lozenge decals. The decals are very, very nice. By following Wingnut Wings’s recommendations, I found the Cartograf decals easy to apply and I did not encounter the kinds of problems some people have reported. The decal film is very thin but durable and will settle into every recess and show every detail underneath, so it should be treated with reasonable respect when being applied. After first airbrushing a coat of glossy paint on all of the plastic parts, I found that placing the decals in warm water, allowing them time to release from the backing sheet, sliding them onto a wetted surface and pressing out any air bubbles while blotting them with a piece of paper towel avoided the wrinkling problems sometimes mentioned in reviews. I did apply a little Gunze Mr. Mark Softer setting solution along the edge of each decal with a small brush and then applied heat with a hair dryer as recommended on the Wingnut Wings website. I airbrushed Future over everything to assure the decals were sealed in place.

This review will conclude in Part 2. However, I can say already this is a great kit, and a pleasure to build. It is highly recommended. My thanks to Wingnut Wings for providing the review kit and IPMS/USA for permitting me to build and review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews