Exterior PE for Trumpeter A-6A

Photo Etch. Some love it, others hate it. This guy has a love hate relationship with it as well, but this was one set that I was more than capable of using without any serious issues. To my knowledge I only created 4 new cuss words, but they were my own doing and not the products fault. With that being said, let’s look at what the folks at Eduard sent my way.

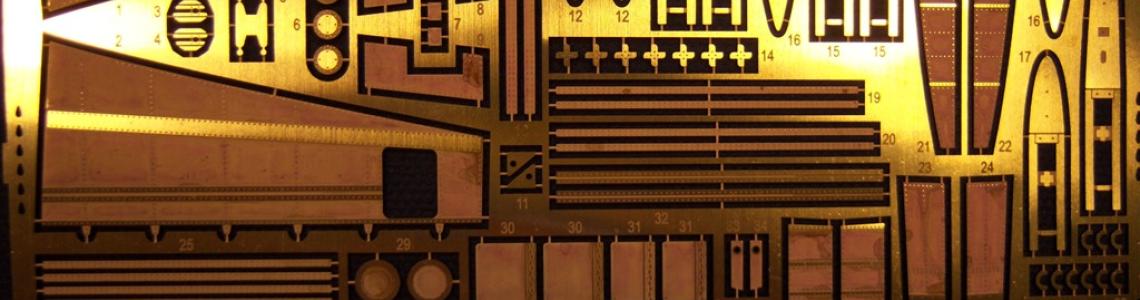

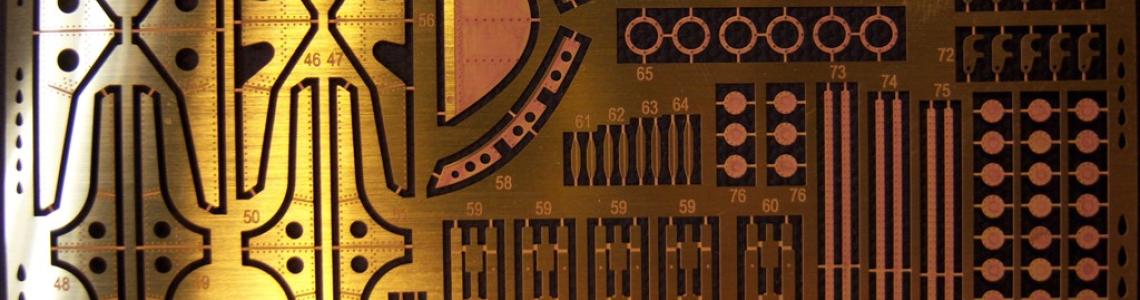

This set is for the exterior of the plane. I didn’t use all of the included pieces, but did use probably 95% of what came on the two brass frets. Looking over all the pieces and where they go showed that it shouldn’t be as daunting as I thought. Yes, there are lots of them, but what parts I did use, all fit extremely well. There were some areas where I would skip using the PE if I were to do this again (I will get the chance by the way) as the kit parts would do the job just fine.

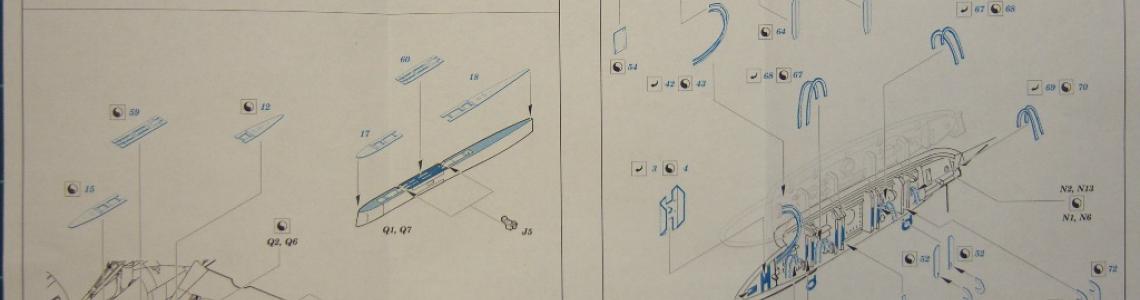

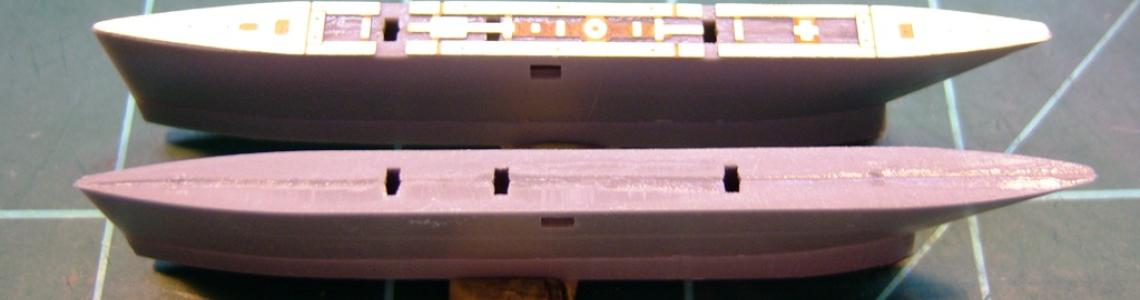

I decided early on that I was only going to open one side of the plane to show off the engines. The kit is set up to display all of its guts, but there is a whole lot that is missing in the kit that I would have to replicate/build in order for it to look right to me so I decided to only open up the one side. That was going to be tricky enough as it was let alone trying for both sides.

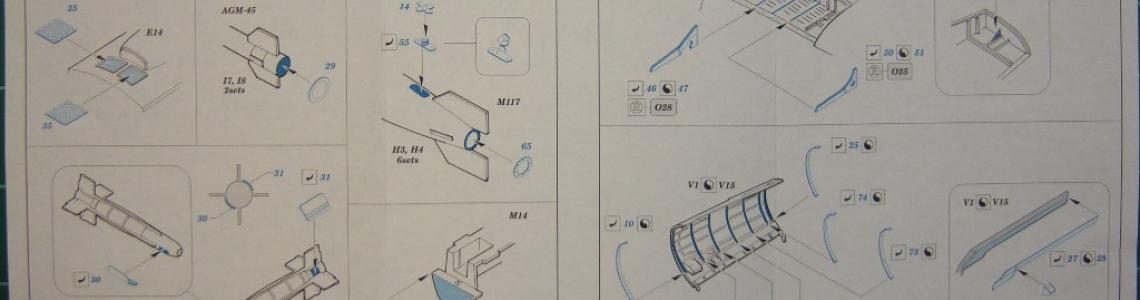

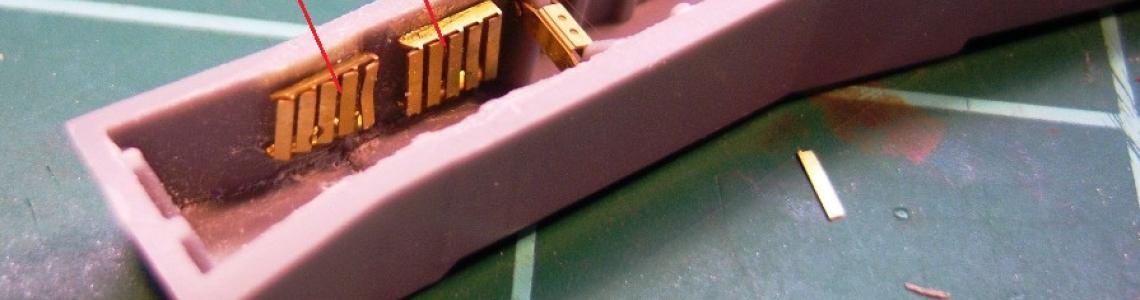

My plan of attack was to install and or replace everything I could as long as it wouldn’t hinder assembly later. Luckily, I was able to replace everything called for in the set without any major hang ups. The first parts replaced were the flare/chaff dischargers on the retractable maintenance platform. These were simply drop in parts replacing the kit parts for a smooth, clean look. Rather than moving onto the next called for item (bombs) I opted to tackle the engine access doors.

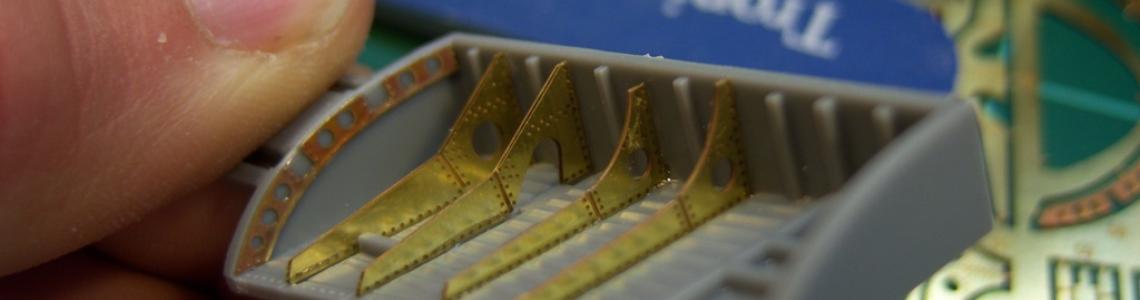

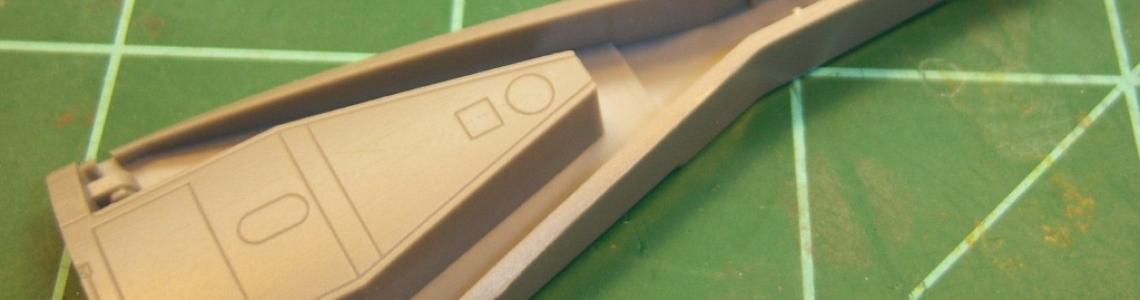

Using a fine sanding drum in my Dremel I was able to remove the molded-in rib running the length of the door without causing too much damage to the surrounding detail. This would allow the PE replacement to lay flat. I few passes with some fine grit sandpaper and I was ready to install the PE replacements. There is one piece that must be bent into a long box shape before being added to the inner door. It would benefit the builder to have an Etch Mate with the long bed on it in order to do this. I imagine it can be done without one, but mine definitely came in handy for this stage. Adding the interior panel to the door was a little nerve wracking as I could see it becoming misaligned and setting up before I could straighten things out. For this reason I opted to use a slow setting CA instead. Epoxy might also be a good choice for this. I was happy with how these came out.

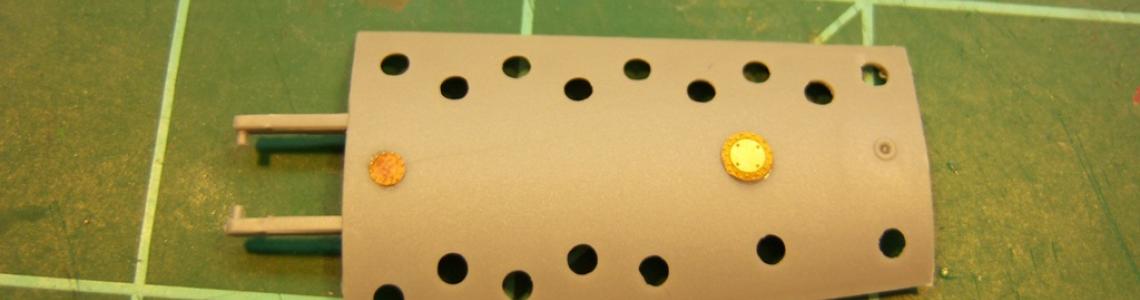

The air brakes were next in line. This is where I didn’t use replacement parts as the plane I was building didn’t have the holes on the air brakes covered/faired over, but were open. The set provides approximately 39 round covers/plates to cover these holes. I test fit one in place and they do cover the holes in the brakes nicely, but I didn’t use them. Next was the air brake bay itself. Folding and installing the braces and other small parts went well. The kit supplied hydraulic lines fit in and around them without any problems once I figured out how they were to be routed.

Moving on to the rear doors for the engine was next, parts V1/V15. These received simple replacements over the existing detail on the kit parts. A small piece of the kit door is removed in order to add its PE replacement. I HIGHLY SUGGEST removing these pieces one at a time from the fret and not removing all of the PE pieces at once as they are different lengths and are easily confused with one another…don’t ask! Once they are all in place the doors take on more depth and detail. They should look really good under paint and weathered up properly.

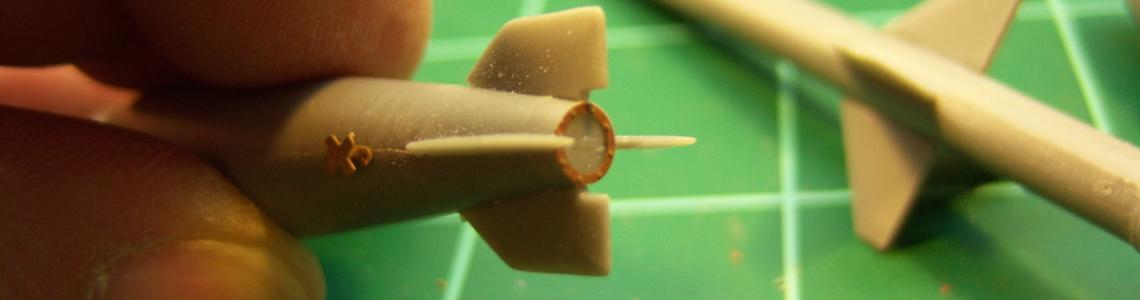

One of two complex pieces/parts was next; those being the wing folds. There are lots of little parts to add here after removing equally small sections from the kit parts. Careful trimming and a few test fits showed I did it right…thankfully. I did learn that the tie down rings added aren’t supposed to be used unless you want to do one that is actually tied down or say a museum piece. They were easy enough to remove though. I replaced the larger flat PE pieces that are the hydraulic lines with small lengths of solder as they looked more the part, but used the PE ones for the smaller areas. The other complex areas to deal with are the vents located on either side in the tail hook area. They are to be removed from the kit part and replaced with the PE parts (Pt #36) that need to be bent to shape. They are small louvers and don’t take kindly to too much handling. I gave it my best shot, but the PE parts are small and extremely fragile and I ended up breaking part of one and barely managed to get the other installed without deforming it too bad. When I do this build again I will omit this part as you cannot see it once the tail hook is in place. The other item here that should be omitted is the small brace/lock that keeps the tail hook in place and is removed before flight ops. It spans the small channel the tail hook rests in. The remainder of the PE for this area is a straight forward affair and adds some good detail to this area.

With the harder assemblies completed it was time to move onto the wing pylons and weapons. These were straightforward assemblies and took no time at all to knock out. They do add a great bit of detail to the kit parts. Various panels and rings are added to the otherwise bland looking ordnance provided. With these last bits added it was time to begin assembly in preparation for the paint booth. I made good progress but sadly this big Intruder did not survive to be completed and met an untimely death. The last picture was as far as I and it got before its demise. When I build this kit again, I do plan on picking up this detail set as the kit does benefit from its use.

Thanks to Eduard and IPMS/USA for the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews