Danish Draken Pylons

Background

Denmark was Saab’s first export customer for the Draken, designated 35XD by Saab. The Danes used a slightly different nomenclature with F-35 representing the attack version, RF-35 the reconnaissance version, and TF-35 the training version. Denmark initially ordered 20 F-35, 20 RF-35, and 6 TF-35 Drakens, with another five additional TF-35 Drakens pieced together after the Draken production line had shut down and switched to Viggen production. The Danish Draken had a 40% increase in internal fuel capacity and had its fuselage and wings beefed up to allow a maximum of 10,000 pounds of ordinance to be carried on nine beefed-up pylons. Externally, the Danish Drakens can be spotted by the larger ordinance pylons and an arrester hook. The Draken had always been designed to have an arrester hook installed, but it was never installed on any Draken but the 35XD. The Danish Drakens also carried two 30mm cannons. The extra weight, going from 12,270 kg to 16,000 kg made this the heaviest Draken. To compensate, the landing gear were beefed up and new tires with a higher tire pressure was used. Although the Danish Drakens only represent 51 aircraft, they served for 23 years and went through a number of modifications that altered their look. Additionally, 13 Danish Drakens made it to the US, serving with Flight Test Dynamics and the National Test Pilot School.

A key feature, the ordinance pylons, were not provided in either the Hasegawa or Eduard releases of the Danish Draken. The Hasegawa and Eduard releases do provide ordinance pylons, but they do not represent the Danish versions. Maestro Models had previously released a set of six pylons in their MMK4827 detail set.

The Detail Set

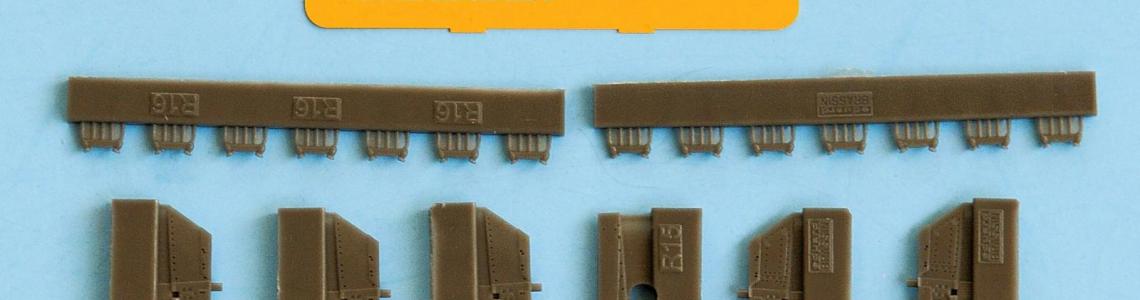

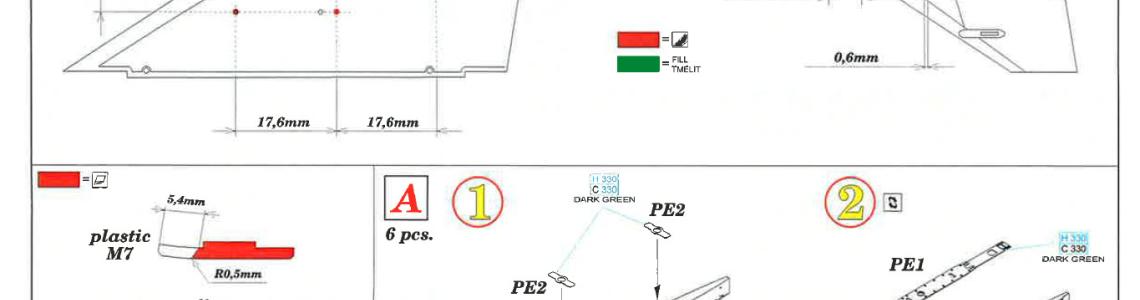

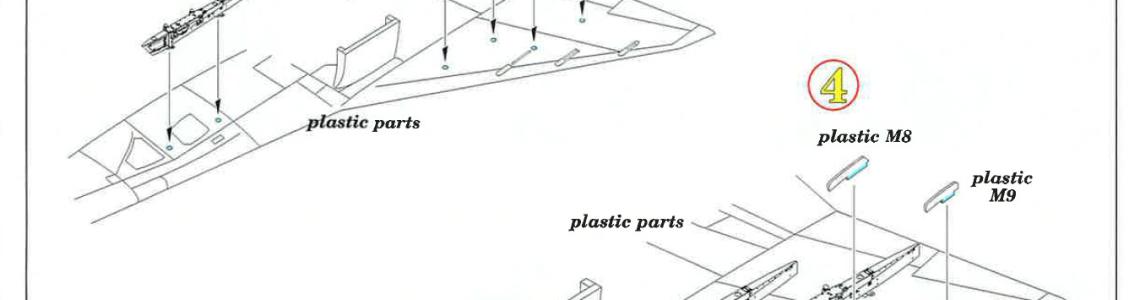

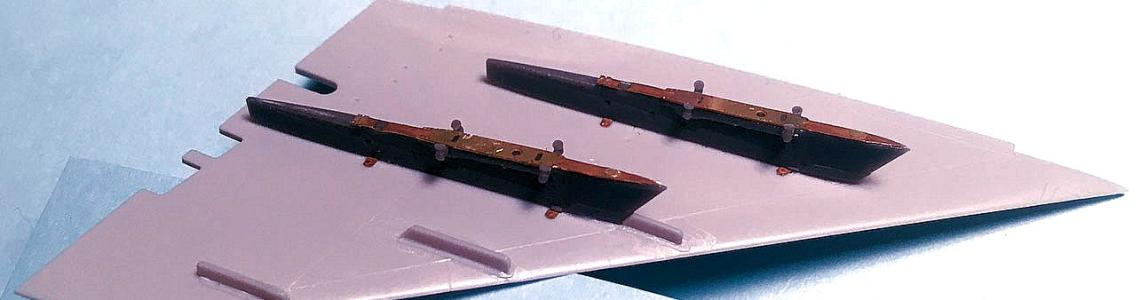

Eduard has released a set of Danish Draken pylons in conjunction with the release of their Limited Edition 1135 kit that features a Swedish, Austrian, Finnish, and Danish Draken. This set replaces the kit fuselage pylons and the outer wing inboard pylons. It also provides a third set of outer wing pylons. The Eduard set is composed of the six pylons and twelve mounting sway braces in grey resin along with 18 photo-etched parts. The components are packaged in Eduard’s standard re-sealable bubble pack. The resin looks very good and there are no discernable bubbles. The photoetch sheet is well secured by a foam backing as are the resin parts. The resin parts can still bump into each other, but I was not able to discern any damage. The instruction sheet requires study before you get going, as there are several alterations to the kit plastic that need to be made. One watch out: Follow the directions on the alterations and measure – the drawings are not one-to-one. The original Eduard release included decals for their 1/48 Bf109 instrument panel, but that issue has since been corrected with the decals (three different decals per pylon) intended for the Danish pylons.

Construction

First off there are two parts to the construction. First is the assembly of the pylons themselves and second is the modifications to the kit that have to be made. This set will need to be installed with your favorite CA (super glue) or epoxy, as the normal plastic glues or solvents will not react with the resin or photoetch.

I started pylon construction with removing the pylon (R15) from its sprue. This is a fairly long cut – the length of the lower pylon. I used a photoetched saw to do this and then sanded the residual sprue flush with a sanding stick. It is critical to get a smooth, flat surface both in length and across the surface of the pylon, so that the photoetch (Part PE1) will lay flat its entire length. Next, you will need to make two perpendicular cuts to insert the front and rear sway braces (R16). Again, making your cuts at 90-degrees is important so the sway braces don’t lean forward or rearward. I modified the steps in the instructions by gluing the resin parts together first and then attaching the lower surface of the pylon (PE1). Once dried, I attached the rear pylon mounts (PE2) to the upper surface of the pylon around the pylon mounting pins. The front pylon mount for the inboard outer wing pylon is at an angle (see the kit part). In this case I did not superglue PE2 until I had properly positioned this part (again see the instructions and look at the front pylon mount to see the angle). Be very careful with both photoetch pieces. They are very thin and will bend in some offbeat direction if you hurt their feelings.

The second part involves modifying the fuselage and outer wing to accept the Danish pylons. The first part is easier as the holes are already partially drilled on the inside. I would still suggest you test fit before drilling holes but, I had no real problems. I used a #61 (0.0390” or ~1 mm) carbide drill bit for all holes and then used a mini round file to open the holes until the pylon wing mounting pins fit properly. Preparation for mounting the fuselage pylon was less than two minutes.

The outer wing has some partially drilled holes on the inside of the lower outer wing, but you can only use one of them. I used a straight edge for the inboard set of holes and scribe a line with a #11 blade form the forward pre-drilled partial hole back past the rear inboard predrilled partial hole. I then used the Danish pylon to find where the rear pylon mounting hole should be. You can also follow the directions and use a digital (or pre-digital if you refuse to enter the modern world) micrometer to do the same by following the dimension in the instructions. You will now need to fill in the Eduard panel lines that represent the pylon mounts on the wing since you will be adding a new photoetch pylon mount (PE2). Most of that time was carefully cutting the parts from their sprue and then sanding to remove any residual resin sprue or photoetch tags.

Following the instructions, I then drew a perpendicular from the inside outer wing rear hard point mount. This ‘hole’ is already there but alas is in the form of a slot. The instructions will have you remove the raised faring on the face of the lower outer wing from this point to the rear of the fairing. I then scribed a line from that point 17.6mm to the rear (see the instructions). Again I used a #61 to drill the holes for the pylon mounting pins and used a mini round file to open them up a bit until the fit was good. You will also need to modify the Eduard kit part M7 by removing plastic for it to be a fairing into the front of the outboard outer wing pylon. Eduard kit part M8 will also need to be modified similarly although not as drastically – see the instructions.

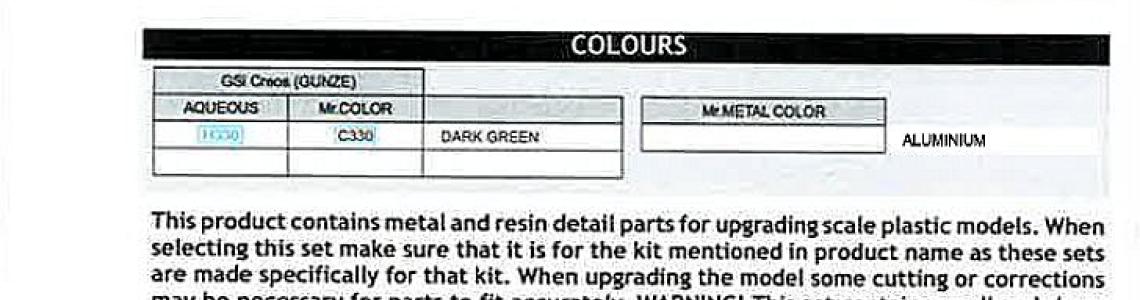

Painting and Decals

Although most paints will adhere to resin alone, I would recommend that you wash the parts to remove any remaining mold release. After mounting the pylons, I primed with Tamiya Light Ghost Grey. I then painted the mounted pylons Tamiya Dark Green for the purposes of this review. The actual Danish aircraft were painted a dark green specific to Danish aircraft. The Eduard kit calls out Mr. Color C330. In reality, this was a matt dark green that faded very quickly. Check your references and you will spot all sorts of gradations of dark green to a heavily faded green.

I used Future to prep the surface for the decals. They went on without any issues and reacted well to Solvaset. A final flat coat was used to remove the gloss and seal the decals.

Overall Evaluation

Although it first seemed to be quite involved, once I got going, this was a fairly simple set if you just take your time. This pylons went together quite well and the modifications to the outer wings are well described in the instructions. I am quite pleased with the overall look of the Danish pylons and feel that they are well worth the cost and effort. If you are going to build a Danish Draken, whether for the Eduard Limited Edition or the several Hasegawa Danish Draken releases, you will want this set. Highly Recommended

My thanks to Eduard and IPMS/USA for the chance to review this great kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews