D9R Doobi Big Ed Set - Part I

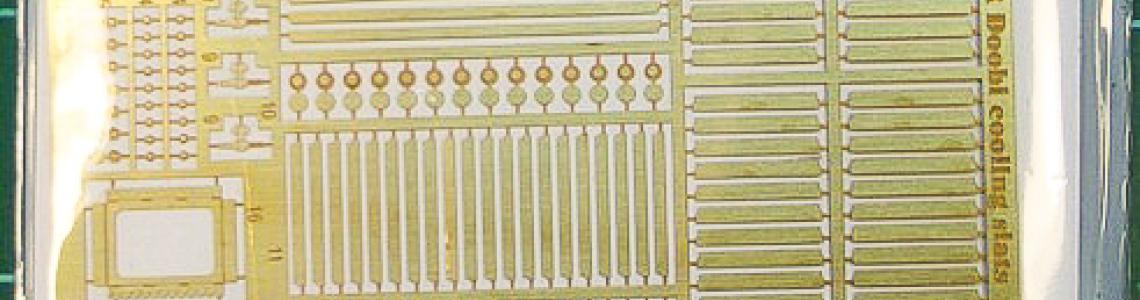

First off, the MENG D9R kit is a beast, but it’s a beautiful piece of modeling goodness once you get going. The Big Ed photoetch (PE) set that Eduard has designed for this kit is an exceptional addition. There are some rather tedious steps involved if you plan to use the entire set of PE, but it isn’t out of reach if you’re patient and pay attention to what you’re doing. The set consists of three separate smaller sets: 36265 Exterior, 36268 Interior (color), and 36270 Cooling Slats. In part one of this review, I will focus on the cooling slats and interior. I’ll follow this up with the exterior set in part two.

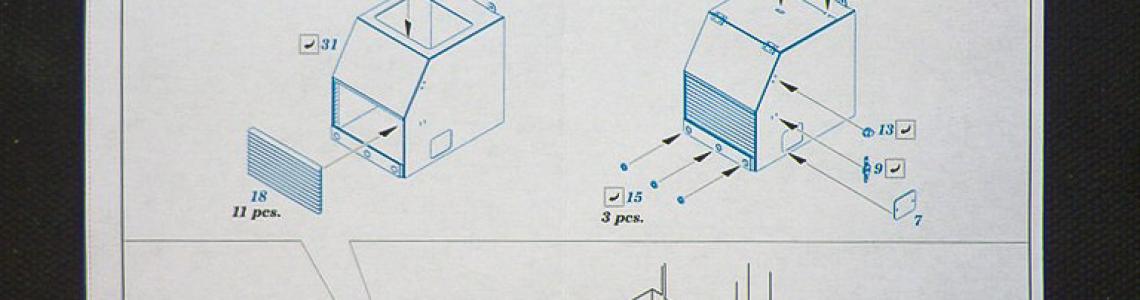

I started with the cooling slats as this seemed to be the best place due to all the handling required for the smaller items later on. Step one has you fold up an exterior box for the dozer; I’m guessing it’s a generator housing or some such item. Well, as luck would have it, I folded it backwards and didn’t catch the mistake until it was too late—go figure. I chalked this one up to experience and moved on. Check your folds often, before actually folding/soldering/gluing, and you’ll save yourself lots of headaches. I solder all of my PE joints, so undoing this would have been more trouble that it was worth; probably painful as well.

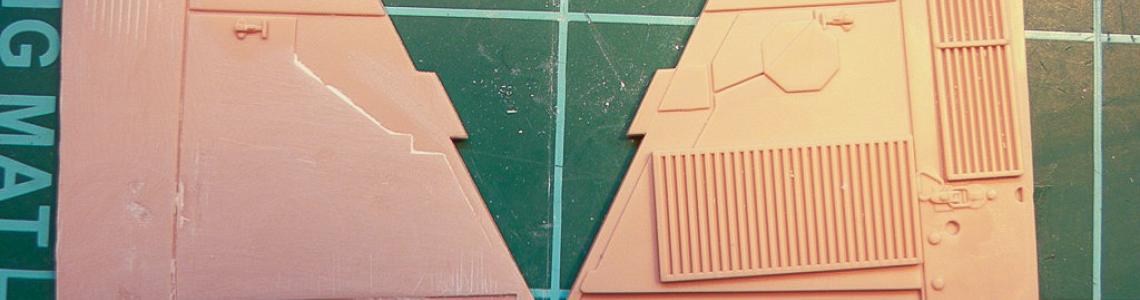

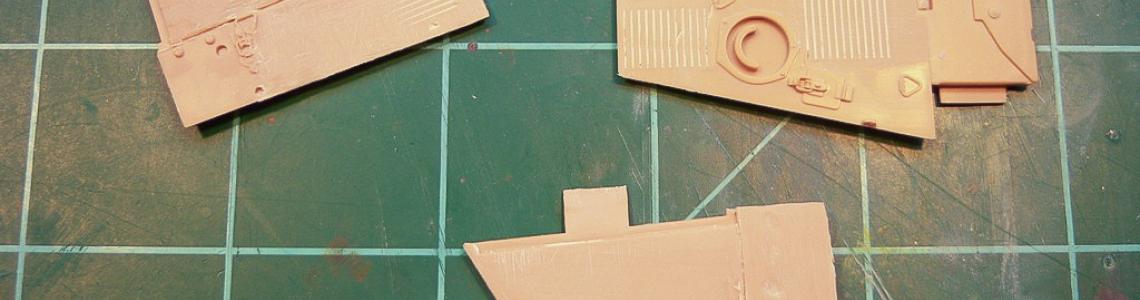

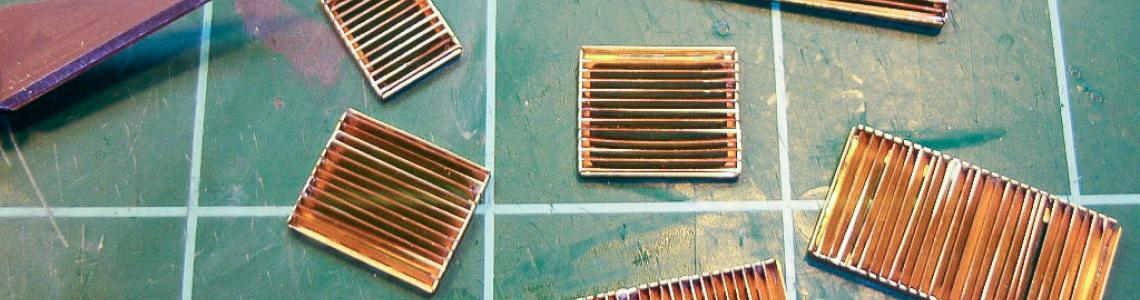

Page two is where I spent the majority of my time with this set, as it requires the removal of all the molded-on cooling slats on the engine cover. There is plenty of surrounding detail next to the cooling slats, so one cannot just throw caution to the wind and blindly start removing them via Dremel and a sanding drum. Some of the detail can be replaced with PE items later, but other portions cannot. I spent the better part of four to five hours trying to carefully remove the molded on cooling slats and was pretty happy with the end results. Assembling the PE cooling slats will try even the best PE worker’s patience, as there are a metric boat load of small parts to attach to very fragile frames. I was able to get them built, but perfect alignment was not in the cards. With that being said, I saw enough of these things in the desert that a few bent and dinged slats looked like what I remember seeing. A happy accident if you will.

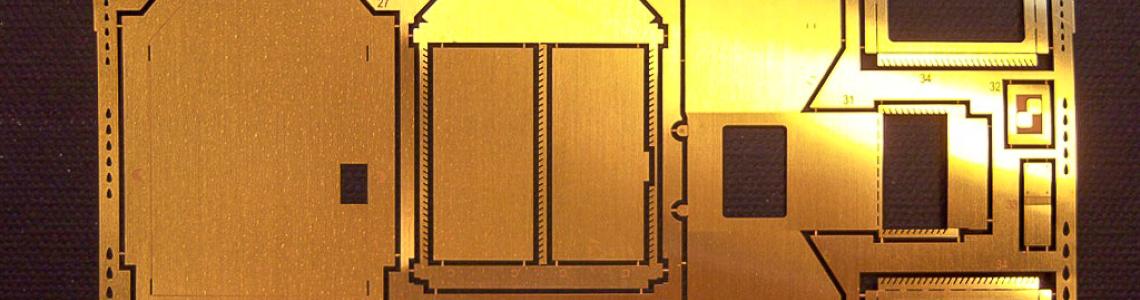

The largest section to build is the front of the dozer. It is actually made from a backing of solid brass with a delicate frame. The frame must be bent to shape and attached to the backing plate. This is followed by 36—yes, thirty-six—individual cooling slats that are inserted into angled slots in the frame work.

I developed a method for attaching the slats that worked for me, while also allowing me to keep most of my sanity. Once the frame work was soldered to the backing plate and everything looked relatively even/square, I dropped the cooling slats in place using a small amount of flux on each end to initially hold them in place. I then carefully used some poster tack to hold the entire section in place while I went back and soldered the ends. Was it tedious? Yes. Did it work? Yes again, thankfully. I tinned the remainder of the backing plate where the other small bits and bobbles would be attached and made short work of getting them added. I used the same mounting technique for the remaining cooling slats. Again, they didn’t come out 100% perfect, but they look like what I remember seeing in the desert: bent and battered to an extent.

With the exception of the malformed box starting out in step one, the assembly was pretty smooth. The removal of the molded-on cooling slats was tedious and, at times, boring work, but it has to be done to use this set. If I do another one of these, I’ll make damn sure I figure out where my folds need to be!

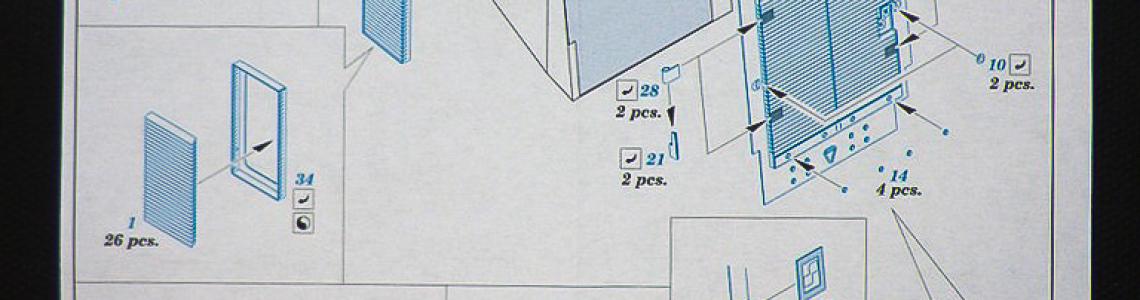

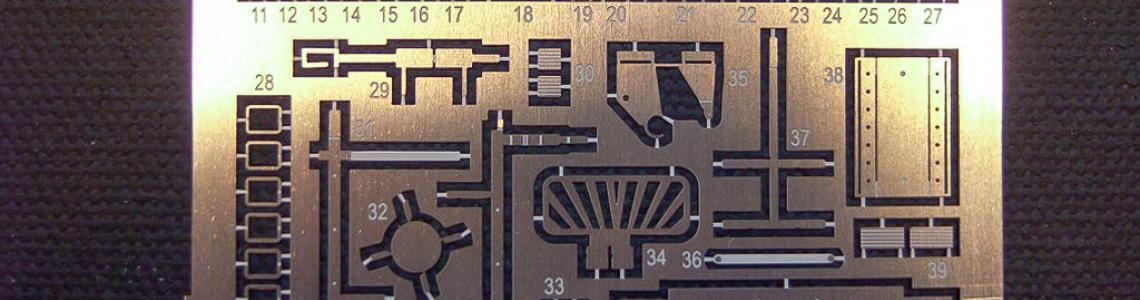

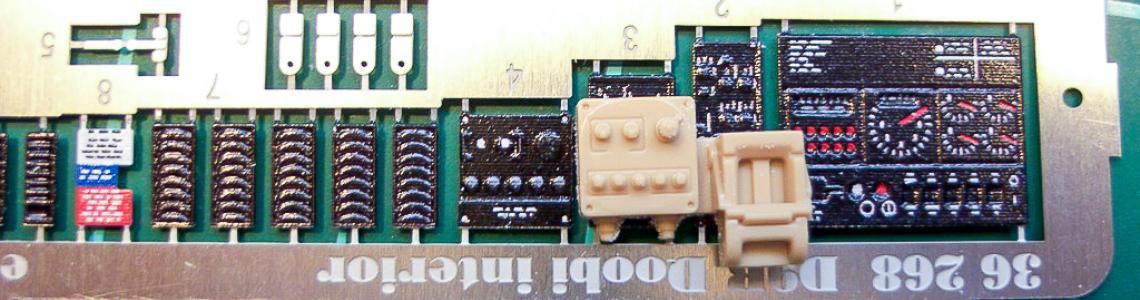

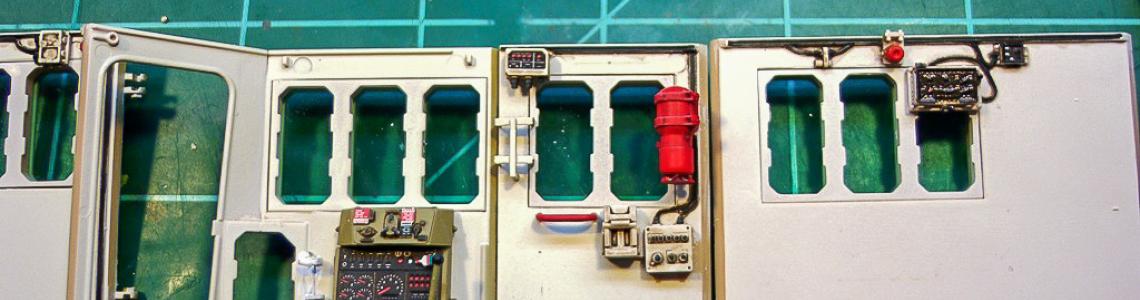

Moving on, the color interior set was next on my list. This set consists of one small fret with colored items making it easier to detail the oh-so-busy interior of the Doobi dozer. There are a couple of areas that need to be removed from the kit in order to use the color PE, but they are easily dealt with using a sanding stick or micro chisel. These areas included the A/C cooling vents and raised detail areas of things like radios, commo boxes, and the instrument panel. I didn’t sand each and every one of them off as some of the PE parts just fit without a need to. In general, my assembly process started with the parts need to be sanded off, and then moved on to installing the PE parts which were not pre-colored. These unpainted parts needed to be installed first, so that they could be painted along with the rest of the interior. Only once the interior painting was complete, could the colored PE parts be added. I almost messed the order up big time; never watch TV while working on something like this!

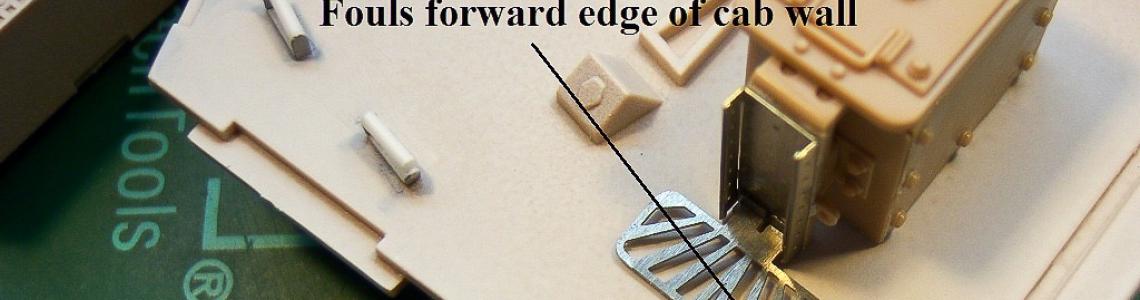

Everything in the interior set fit well, with one exception: the foot platform for the left-hand operator. I had to trim its front-left corner off otherwise it would foul on the forward edge of the cab. Even the kit part would have done the same thing, so it’s a wash really, and at least the PE is thinner. This is not a deal killer by any means, more of an FYI.

With this interior painted and the colored PE placards installed, the office really came to life. If you want to show off the interior, leave the top of the cab loose. Otherwise, you won’t see much once it’s closed up. Even with all those windows, not much light gets in. This is a small set, but the benefits are great. Trying to paint all that detail would be tiresome at best. A few quick passes with the sanding stick and you’re well on your way to adding some excellent detail to your Doobi.

My thanks to Eduard for supplying this set, and my thanks to IPMS/USA for the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews