B-26G Marauder

One of the Last B-26 variants was the B-26F which featured angle-of-incidence of wings increased by 3.5º; the fixed .50 caliber machine gun in the nose was removed; the tail turret and associated armor were improved. The first B-26F was produced in February 1944. One hundred of these were B-26F-1-MAs. Starting with 42-96231, a revised oil cooler was added, along with wing bottom panels redesigned for easier removal. In total, 200 of the 300 aircraft were B-26F-2s and F-6s, all of which were used by the RAF and SAAF as the Marauder Mk III. The F-2 had the Bell M-6 power turret replaced by an M-6A with a flexible canvas cover over the guns. The T-1 bombsight was installed instead of the M-series sight. British bomb fusing and radio equipment were provided (300 built).

The B-26G variant was a B-26F with standardized interior equipment; in total, 150 bombers were used by the RAF as the Marauder Mk III (893 built).

In addition, these later variants had the wingspan increased from 65’-0” for the B variant to 71’-0”, and the height was increased from 19’-10” to 21’-6”.

A nice feature for this kit is an 8-minute video included on the ICM product web page, that shows the step-by-step assembly of this model. This can be especially helpful if the instructions are a bit vague for an assembly step.

What’s in the Box

There are 11 sprues, 9 plastic and 2 clear included. A total of 380 parts builds this model. The instruction manual contains 28 pages with 134 steps. One page contains a template for the canopy masks. Parts not used in the assembly are highlighted. One sheet of decals is included with markings for three different aircraft. Full color plans and profiles are provided for those aircraft.

Construction

The first thing I did was determine the version I was going to build. That was “Willie the Wolf” with the open bomb bay doors.

Fuselage

Steps 2 through 48 address the assembly of the two fuselage halves. Part numbers and paint colors (when applicable) are clearly noted in each step. There is a lot of fine details on both interior surfaces of the fuselage but will be mostly hidden once the halves are fitted together.

I used Vallejo Model Air colors for the finish painting of the interior. The bulkheads and other parts were painted prior to placement. Step 48 notes that a 90 weight is required to keep the nose wheel down. That is a lot of weight!

I used the Eduard seatbelt set (FE1455) for the B version that I had on hand. Also, since I had the Eduard mask set (EX1045) I used that for the clear parts’ exterior surfaces. This set had most of the masks for the clear parts. And where it was short I used masking tape and fluid to cover the gaps.

Before the fuselage halves are fitted together permanently the clear parts must be glued in place.

There are five bulkheads to install before the fuselage halves can be closed. I fitted the bulkheads in place and before the solvent could set up, I fitted the fuselage halves together to make sure the long seams on top and bottom would close properly. Everything fits nicely.

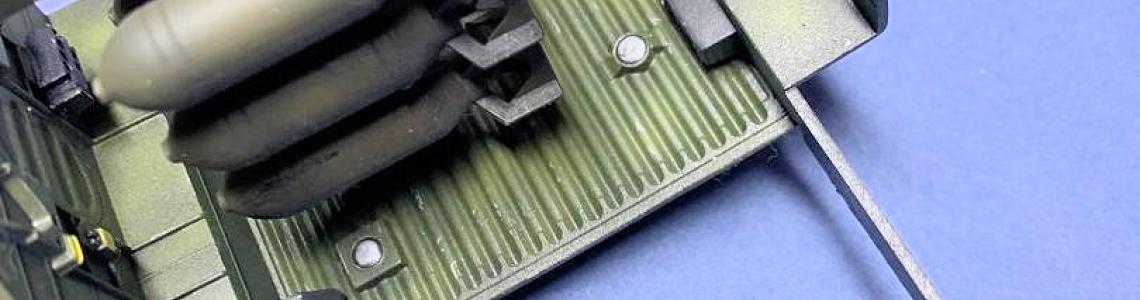

The Bomb Bay Interior and Doors Assembly

The bomb bay interior is very nicely detailed and engineered. The six bombs and bomb racks can be assembled as a unit and fitted into the fore and after bulkheads. I left this off until the model was substantially finished and painted.

The fitting of the open bomb bay doors begins with steps 09 and 47. Parts D41 represent the door hinges, Part D41 is shaped like the letter “J” with one leg longer than the other. The instructions are a bit vague with the placement of the parts, but the longer leg on the fits into a recess on the interior side on the open bomb bay. There are four hinges per side.

The assembly of the open bomb bay doors is detailed on steps 57 through 59. I painted all the parts prior to assembly, and this was the final step in the work. Care is required to properly locate the four sets of door operator assemblies before the doors are glued in place. This is a very delicate assembly.

Wings

The instructions call for the removal of the molded-in-place right wing pitot: I removed the left one off too as I knew I would break it off during the assembly process anyway. I later used brass tubing to replace the port pitot and installed it after the model was painted and decaled.

Each wing is comprised of a top and bottom, plus two bulkheads that close off openings where ailerons and flaps are located. There are separate clear parts for the wingtip navigations lights and the leading-edge landing lights. The flying surfaces may be posed if desired.

There are molded-ion-place tracks for the two spars to slide into forming a fit holding the wings in place. The right wing fit perfectly and was glued in place. The left wing was another story, however. The rear spar would not align with the track and therefore the wing would not slide into place. I placed a length of surplus sprue between the two spars to act as a spreader shim. The wing slid into place and the and the top side alignment was perfect, but the bottom of the wing was too shallow, and a huge gap appeared. I was baffled. I realized the depth of the wing section that abutted to the fuselage was too shallow and would require a shim to increase the depth. Again, I used a short length of sprue to increase the depth of the wing section. .

Engines, Cowlings and Nacelles

Two nicely molded and detailed engines are included. I painted the individual engine cylinder banks separately as well as all the other associated engine parts. Everything was then assembled and ready for fitting in the nacelles.

The propeller shafts (parts D45) are trapped between the engine front and the assembled engines, without glue. The propeller shaft is tapered with the narrow end fitting into the socket at the propeller’s backside. A test fitting of the parts revealed very little contact surface between the shaft and propeller socket. I did not use parts D45 but rather fit a short length of brass tube into the propeller sockets that slid into the openings at the front of the engines. This provided a solid connection.

Each cowling is made up of six parts. All parts fit together nicely.

The nacelles are made up of two halves, plus three interior bulkheads. The bulkheads were a bit fiddly to fit in place and align with the opposite nacelle half. The engine exhausts were drilled out and fitted in placed. Some filler was required on the bottom side seams.

The completed engines are a snug fit when inserted into the cowlings. There was a slight spring back of the engines that created a gap between the cowling flaps that are part of the engine assemblies and the cowlings. I held the engines in place and applied solvent along the leading edge of the cowl flaps and cowling. This eliminated the gaps. The exhaust manifold fitted to the rear of the engines conflicted with the front of the nacelles. I removed the manifold parts and glued the engine/cowling assemblies in place.

Landing Gear and Wheels

The tires are made from two halves and required some effort to get the halves aligned properly. The hubs are separate parts (inside and outside halves). The tires and hubs were painted separately and assembled afterwards.

Parts 25 and 27 are molded as a shallow “V” shape with one leg longer than the other. The short legs fit forward and slip into opening in the forward bulkhead. The instructions were a bit misleading with this detail, however the ICM instructional video helped clarify this detail. The “elbow” of the parts fit into shallow slot in the roof of the wheel well. The main landing gear fits into three shallow dimples in the roof of the wheel well. The dimples should all be drilled through the plastic for a more secure fit when placing the main gear. This should be done before assembling the engine nacelles. I applied a dab of gel super glue on the roof of the gear wells, where the main gear leg is attached for added strength.

Painting

The model was primed with Mr. Surfacer 1500 Black, thinned with self-leveling lacquer thinner.

The undersides were painted with Alclad aluminum, while the top side was painted with LifeColor olive drab,

Once the paint had been cured the model was given a clear, gloss coat using Alclad Aquacoat.

Decals

There are three marking optioins for this build. The ICM decals are thin and respond to a quick soaking in water.

I decided on the “Willy the Wolf” markings for this build. Each decal was floated in place in a pool of MicroSet. Once located the excess MicroSet was wicked away with a folded paper towel. The long black strips for the wing walks should be cut into third or in half for better control when placing them on the surface. Solvoset was used to allow the marking to conform to surface details.

Once the decals were dry, I used ModelMaster clear flat to seal everything in place.

Conclusion

The instructions show 134 steps to the assembly, although appearing complex, are reasonably easy to follow thanks to the breakdown of the assembly steps. The builder is not overwhelmed and confused with trying to place several parts in the various subassemblies in a single step. In the event there is some confusion on parts placement or the orientation the ICM website B-26G assembly video will clarify the placement.

The smaller parts require care when removed from the sprue. Many of those parts have a short gate between the part and the main sprue requiring the use of a hobby knife to cut the part free,

The molding of the parts is crisp and well detailed. The plastic is a bit soft but was not an issue during the assembly.

Ease of assembly and fit is top notch. I thought the model was very well engineered. This kit is not for beginners.

I would like to thank ICM and IPMS/USA for the opportunity to build and review this kit. I highly recommend this kit for the experienced builder. It is not for the beginner model, due to the many parts and complexity.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews