Resin Wheels and Tires for 1/48 F-16I "Sufa" (Storm)

IPMS/USA thanks the crew at Aires for supporting the IPMS USA reviewer corps with one more of many monthly releases, In this case another example of CAD-assisted resin wheel and tire assembly. This is a useful and timely landing gear addition in the ever-growing detail world for the sufferers of Advanced Detail Syndrome like me. And thanks to IPMS leadership for sending it my way to be reviewed.

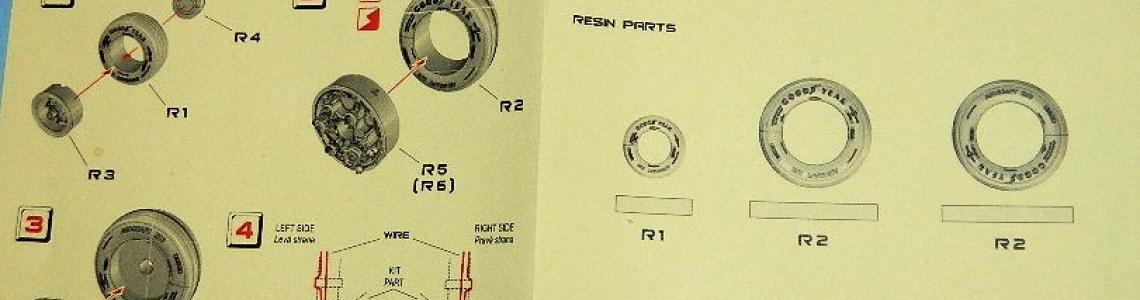

This review is of the Aires/Wheeliant F-16I Sufa’s wheel and tire set. It is truly an improvement over the basic kit items, as a mere glance at the photos can show. The one really noticeable bit is the writing on the tire sides (“Goodyear”), and the deep, scale tire grooves of the “heavy” landing gear rubber. Be aware that 148018 is the set for Kinetic’s Sufa, and 148016 is the Hasegawa version. There are differenced in the axle arrangement, etc.

If anyone else has been wondering how we have been able to have a plethora (‘Three Amigos Anyone?) of wheel and tire assemblies with legible microscopic company logos and title detail on the sidewalls, mark it down to Computer Assisted Drawing (CAD) and 3-D printing. These items make use of its powerful abilities to convert just about any small item into a three-dimensional item for 3D printing of a repeatable master, in this case the tire. This is then duplicated into a silicone mold, which is then used to resin cast our parts in detail far beyond standard styrene plastic items. This tutorial is free to those who have not paid attention over the past four years of technological advance, who probably also believe models should still cost .98 cents. The last bit is a Topic for another time.

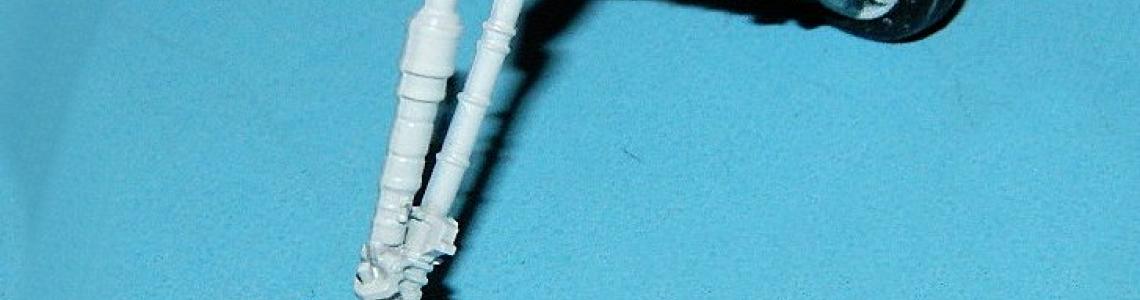

In the case of this Wheeliant © set, the detail extends across the spectrum; the 10-piece set includes three resin items per assembly (a wheel outer and inner face, and a one-piece tire in resin), and a length of copper wire to simulate brake hydraulic lines. THE FILLER VALVE IS VISIBLE BETWEEN THE DEEP MAIN WHEEL SPOKES! Amazing…

The set requires you to remove the resin parts from their pour gates, (I prepainted my set first), and the install the wheel halves within their proper location on the single wheel. I used a hacksaw blade to cut the resin free, and it was easy going with a flush result.

I also recommend you sand down the back of the brake and main wheel hubs about ½ millimeter shorter than the parts fit, because my wheels are standing proud of the tire and “that ain’t right”… they should fit flush.

All parts fit well and within their respective mounting sockets on the hubs, allow the kit or aftermarket metal gear axles to fit slightly loose so you can adjust toe in, camber, and alignment. Apply a bit of superglue (thick) to the axle, and press the brake hub in place. Then adjust both wheels to look “right”. The nose gear is easier, as you can glue the hubs to the wheel, let it cure, then install so the flats are correctly located. If so inclined, you should install the brake lines, which are shown on the directions. I have not decided yet…

This is a simple, easy set that is relatively low cost and provides the UK title, “Value for Money”. Well thought out and engineered, and it all fits correctly. Top score here!

Thanks again to Aires/Wheeliant for working with us at IPMS USA, as we really enjoy reviewing your products/…

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews