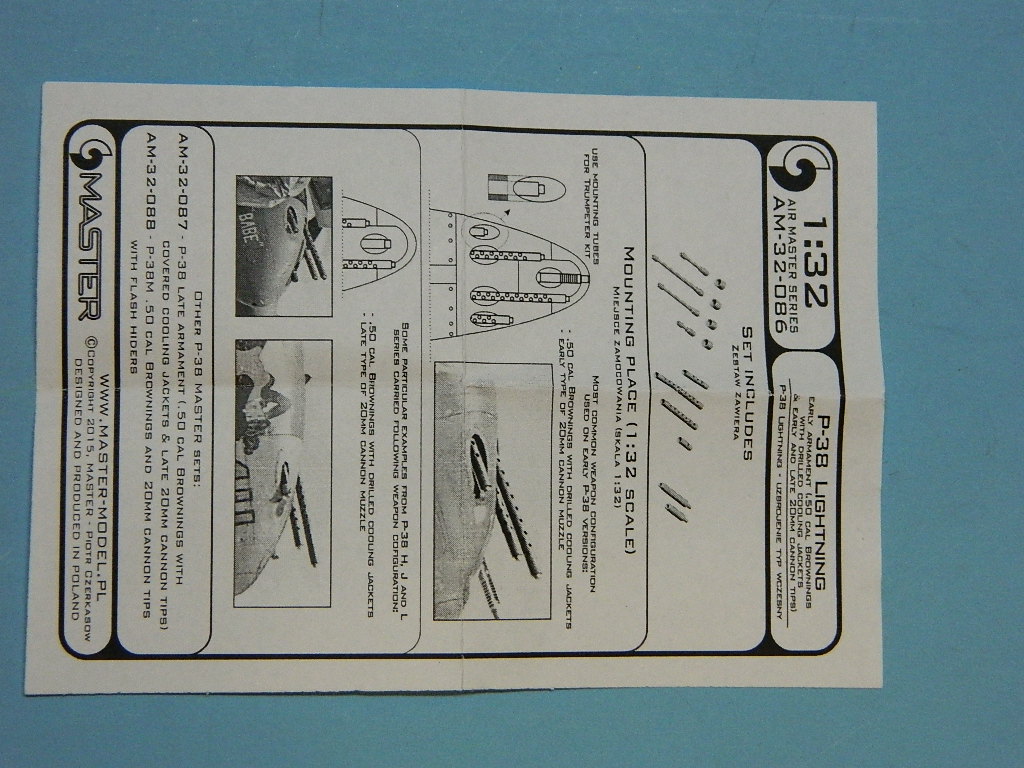

P-38 Early Armament .50 cal Brownings w/ Drilled Cooling Jackets

Master Models once again provides IPMS USA with examples of machine-shop excellence… We are extremely thankful to Piotr for providing examples of his work to review.

As you can see by the product photographs, these .50 caliber browning machine gun barrels are exquisite works of art. Designed to fit one of the two 1/32 Lighting models currently available, you receive four different length .50 caliber barrel assemblies, and two separate types of 20MM cannon barrels which were utilized on some variants of the Lightening.

What is really impressive about this set is you are provided with the drilled cooling jackets, which I challenge anyone to do at home with tubing and your personal micro drill set! I know I can’t… so this is one area (of several) where Master Models’ products shine.

Besides the cooling jackets, you are provided with hollow barrels, and mount rings,

One area I have struggled with in the past is the finish of these barrels. I have used my trusty gun bluing pen in the past, with mixed success, as the brass does not absorb the color and tends to scratch off. So it was time to try something different… that would be Gun Bluing liquid. Birchwood Casey “Super Blue” is what I found worked well. I picked mine up at my local gun store; for those places in the world where personal ownership of guns is outlawed, maybe you can have your local military guys get this for you.

Note: PLEASE wear eye protection, and latex/silicone gloves are also a good idea; you don’t want this stuff in your skin or on your eyes, it can blind you. Safety lesson over…..

This clear acidic liquid is intended to be swabbed on gun metal, and actually etches into the metal for a light corrosion of the base metal (that’s how it works) which then provides a blue-black finish. Designed for steel, I found applying the liquid with a swab worked well. However, I had to keep turning the barrels over, which can be an issue because Mr. Tweezer is not our friend on round smooth-surface items like these brass parts. I thought about dipping the parts, but was concerned about dropping the barrels into the bottle… but in a moment of “Where is your brain”, I hit my self with the idea of decanting the liquid into a poly epoxy mixing cup. This way I could drop the parts in, let them etch for a few minutes, then pull them out and put into another cup to rinse with with water, which stops the etching process. THIS was brilliance. I patted myself on the back and moved forward… Polish the surface with a soft cloth, and re-dip if required until finished!

After the bluing process, I proceeded to assemble the parts. I learned the etching did not affect the surface to the point I could not slide everything together (a real concern, as the machine tolerances on these parts is very tight). If anything it made them easier to build, as they didn’t keep sliding apart. Another dip in the etching fluid to touch up the scratches, water rinse, I used a touch of thin superglue to lock the parts in place; I now had the best-looking barrels available to install in the pride of place on my lighting!

As usual a full 10 rating for these jewels; thanks To Master models once again for producing these fantastic items, and to IPMS USA for passing them on to me for review!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews