F-5E Tiger II Speed Brakes

Aires has been on the scene for some time now, producing some amazing details in resin and photo etch metal. Among aftermarket aficionados, Aires is the top of the pack for the level of detail and quality of casting. This set for the AFV Club 1/48 series of F-5 Tiger II kits is no exception, though installation is a little time-consuming.

In the Box

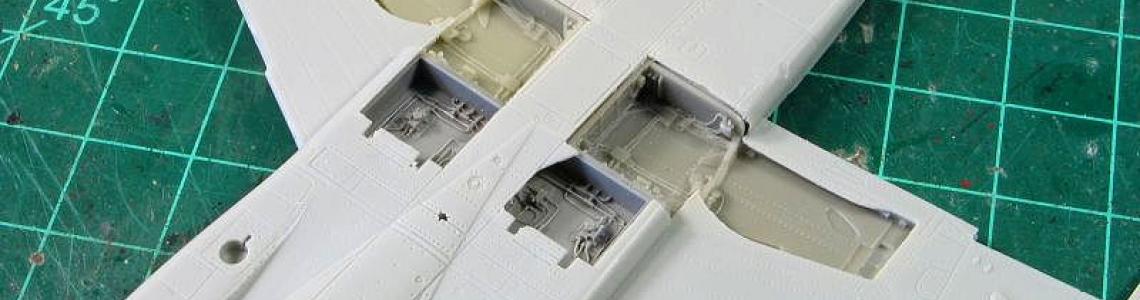

The bag with card hanger comes with seven resin parts. There are two actuation cylinders, two new brakes, and a solid part that covers both wells. There are also two additional parts that make up some side wall detail within the well, so don’t forget them during installation! The parts are finely cast in grey resin with no blemishes or flaws. The detail is great, and very fine. A quick comparison to the kit shows there is marked improvement over the kit details, both in finesse and accuracy. Also, the overall depth of the brake wells is greatly improved with this set, getting it a bit closer to actual depths. The brakes themselves are complete replacements, which is good, as the kit parts have a few ejector pin marks that have to be removed. The resin parts show no such blemishes and even improve the overall detail.

Installation

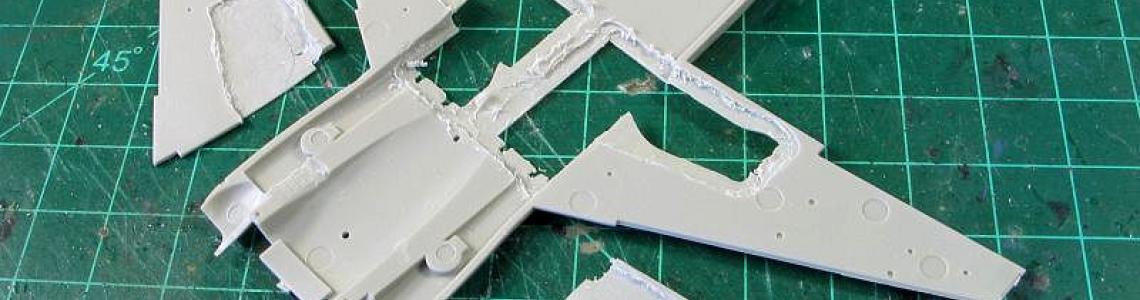

Before you begin, gather the necessary items you will need to perform major surgery on your kit. Along with the usual knife, files, and sanding implement, you will also need a Dremel tool with at least two different cutting heads. I used both a cylindrical one and the teardrop-shaped one. Now, build up enough nerve, because once you begin there is no turning back!

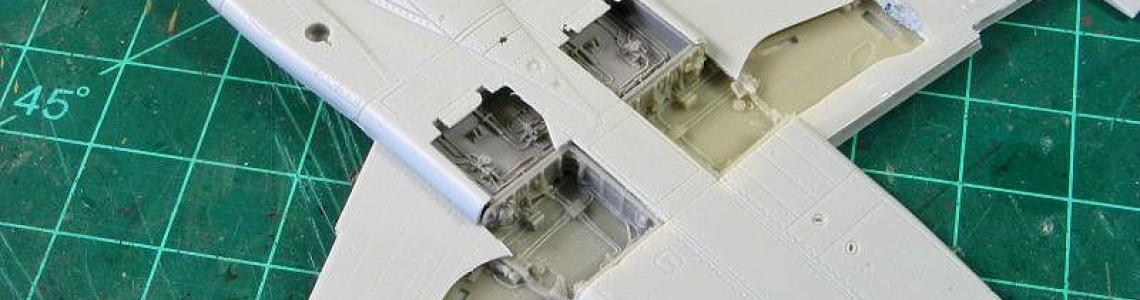

I started by grinding out the kit’s speed brake wells. I started with the teardrop-shaped head, on the tool’s lowest speed, to punch through the kit. I then switched to the cylindrical head and ground out the wells up to the edge of the speed brake openings. Once this is complete, flip the part over so you are now looking at the inside. Now, using the Dremel at a 90 degree angle to the plastic, SLOWLY grind away a shelf around all the openings. Take your time and brace your hands, doing only a little at a time. Once you have a shelf carved out, test fit the resin parts, grinding offending areas of plastic until you get a decent fit. Files and sandpaper cleaned up the job. Since I had the landing gear bay set also, I repeated the process for those areas as well. Keep test fitting and carving until you can fit the new resin wells into the kit.

After removing as much of the resin pour plug as possible, and much test fitting, I finally was able to get the new wells to fit. I did forget the small L shaped sidewall parts, so now must figure out how to slide those in and secure them. Honestly, nobody may notice them missing! The rest of the assembly is easy, with just direct replacement parts.

Conclusion

For the parts themselves, they are beautiful and are more detailed than what is offered in the kit. This set is nowhere near as difficult to install as the landing gear bays, but still requires some nerve to cut into the kit and some very careful grinding of plastic. In the end, I can see the improvement if I look for it, but the casual observer will probably miss this addition of detail. The speed brake wells are on the underside, and are partially covered by the brakes themselves. So, it will be up to the modeler to decide if this is worthwhile for the additional time and cost involved. Personally, I most likely will not use them again, and will instead invest the money in more noticeable areas of the kit, such as the cockpit (with which Aires does a beautiful job!) If you’re looking for that additional detail, though, this is the way to go and I recommend them to the more advanced modeler. Many thanks to Aires for the sample and IPMS/USA for the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews