Bristol Beaufort Mk.1A

ICM continues to pump out fantastic kits in all genres of interesting subjects to the modeling world. This Beaufort is the sixth version to be released. I built the second release that featured tropical filters a couple of years ago, so there were no real surprises with this build.

The standard ICM box lid was adorned with a striking painting of a low flying, dark sea grey over white Beaufort dropping a red nosed torpedo over the water. Grey plastic parts were contained in one plastic bag, with a clear parts sprue protected within its own bag. The instruction manual and decal sheet were at the bottom of the box, along with a color sheet showing ICM paints available.

Following the instruction manual format, construction was set out to ease painting separate items. Components like the cockpit and cabin, landing gear and other assemblies could be completely built and painted in one session which sped up and simplified assembly.

The cockpit and cabin were built per the instructions and ICM included an instrument panel decal. I added many levers to the center console, as well as a left over Kelig 3D printed instrument panel, side console details and seat belts, which improved an otherwise quite bare cockpit. I did not spend much time detailing the center cabin which was all but invisible after assembly. The floor of the cockpit and cabin also served as the torpedo/bomb bay ceiling. There were several ejector pin marks that were shallow enough to sand away.

ICM suggests painting the aircraft interior, torpedo bay and landing gear wells US dark green, but I used British interior green instead. There are a couple of holes to open up in each fuselage half and the wings for various antennas used, plus an assortment of either clear or shuttered windows that needed to be installed before the fuselage was closed up.

After everything, including the tail wheel and three-part wheel well, were installed in one half, I closed the fuselage with no problems. The tail wheel subsequently broke off and, like I did on the first Beaufort I built, I drilled holes and inserted wire to reattach the wheel.

The wings and tailplanes were glued together and the seams cleaned up. The wing roots fitted beautifully against the fuselage sides and no filler was needed. The wing flaps are designed to be displayed down, and I built them down on the tropical Beaufort, but I wanted to build them retracted on this one. I removed the flap mounting tabs and laid them in their recesses. The fit was fine.

I next assembled the main landing gear legs. The use of a razor saw was essential to cleanly separate the fine, delicate parts from their respective sprues. While a little fiddle to assemble the multiple parts together, the end result was strong and looked fantastic.

The two-part main wheels were nicely detailed and attached to two tiny axle stubs at the lower end of the gear legs. I cut these stubs off and drilled through both sides of the legs to insert wire axles cut to length. The result was a stronger wheel to leg.

With the aircraft built, I continued on with constructing the engines and cowlings. The engines were small models in their own right and really did look great when finished.

After painting and detailing all components, the two banks of nine cylinders fit snugly together and I inserted the propellor boss (axel) in the gear box housing. ICM suggests gluing the propellor to the boss at this stage, but I wanted to add the props later, so I glued the boss inside the housing and could press fit the props on later.

Using the instruction pictures, I added the exhaust collectors trying to make sure I had the three supports orientated in the right place against the engine front. Separate exhaust pipes lead from each cylinder to the rear of the exhaust collector. With the engines completed, I put them aside to be attached to the wings later.

The two engine cowling halves were glued together and the seams carefully cleaned up to minimize damage to the cowling straps. The exhaust pipes that were integral to the outside of the cowling were in two parts and went together nicely. Cowl flap rings were then glued to the back of the cowlings.

As the model was closing in on being ready for paint, I attached the cockpit windscreen and “greenhouse” clear panels that formed the nose of the aircraft. Most of these fit well, but I ended up with a slight gap where the right side met in front of the windscreen. I filled it with super glue, carefully sanded it smooth and rescribed the panel line.

All the “glass” was masked, including the cabin windows using Eduard masks. The later style rear turret was masked using the supplied masking template in the instruction manual and transposed onto blue 3M masking tape. The Eduard set only supplied masks for the earlier turret. The clear wing tips were also masked to paint the center panels and frames.

I sprayed British interior green over the cockpit and turret framework, followed by an overall white coat. When this was dry, extra dark sea grey was sprayed within masked off areas on the wings, tail plane, fuselage roof and spine. All paints used were either Tamiya or Mr. Hobby Color. A couple of gloss coats prepared the model for decals.

I chose to model the second painting option and what was displayed on the box lid: Bristol Beaufort Mk. 1A, LR906, No. 2 Torpedo Training Unit, Castle Kennedy, September 1943. The ICM decals were easy to work with and showed good color density. They snuggled into panel lines with a little help from Micro-Sol. There were not a lot on this kit so it didn’t take too long to decal the whole aircraft. A final gloss coat sealed the decals and there was no silvering. Final assembly began after the paint had dried from a panel line wash and flat coat.

I glued the engines in their slots, making sure they were orientated correctly. The cowls were then pushed into place. I did not glue one of them as I wanted to be able to show off the engine detail. There was a vertical tab at the top of each cowl flap circle that needed to be removed so the cowl flaps could fit under the carburetor intake. The parts diagrams didn’t show this tab.

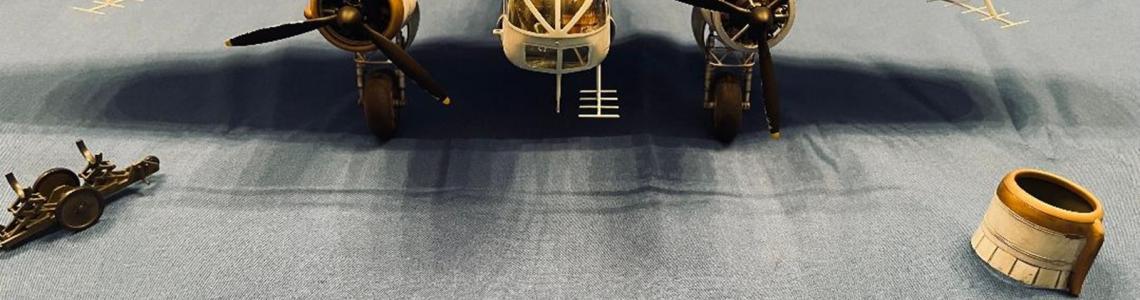

The main landing gear leg assemblies were glued into their respective wells. I also reattached the tail wheel. Gear doors were mounted either side of each main gear well to complete this area of the model.

ASV radar antenna assemblies were mounted to the underside of each wing and under the nose, along with the pitot tube.

I assembled the rear twin Vickers .303 machine gun turret and located it into the cabin floor. Each turret clear halves mounted nicely onto their base and a light touch of Tamiya Extra Thin cement ensured they stayed put.

Two aerials were attached to the cabin roof, as well as a Direction Finding “football”. I used fishing line to make an antenna glued to the front aerial back to the tail. This completed the aircraft build.

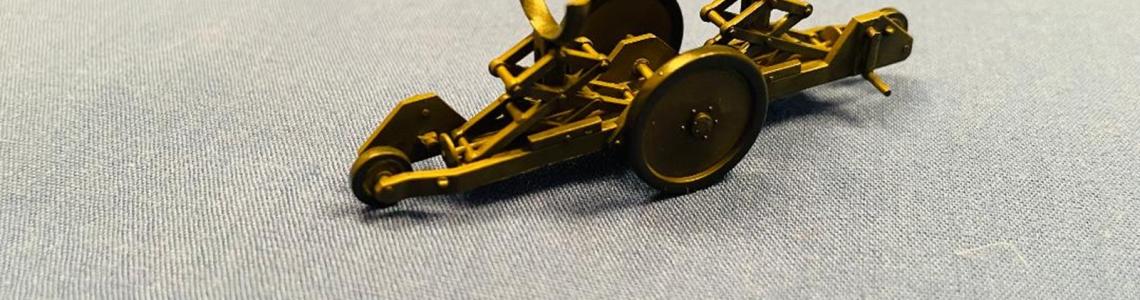

ICM provides a separate sprue containing a British torpedo and trolley. The torpedo went together easily. The trolley was a little fiddly, but looks great when assembled. I loaded the red-nose-painted torpedo onto its cradle inside the torpedo/bomb bay.

This edition of ICM’s Beaufort is a striking representation of the aircraft and brave men who defended Britain during WW2. I would recommend this model to builders with some experience, especially dealing with delicate parts, and removing them from the sprue and some fiddly assemblies.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews