1961 Jaguar E-Type, Part Four

This review covers packs 10 and 11 of the Agora Models Jaguar build. Please see parts 1, 2, and 3 of this review for the first 9 packs and more information about the kit.

Originally, this was going to be the final review for this build. But there was so much ground to cover that I decided to split Pack 12 into a separate review.

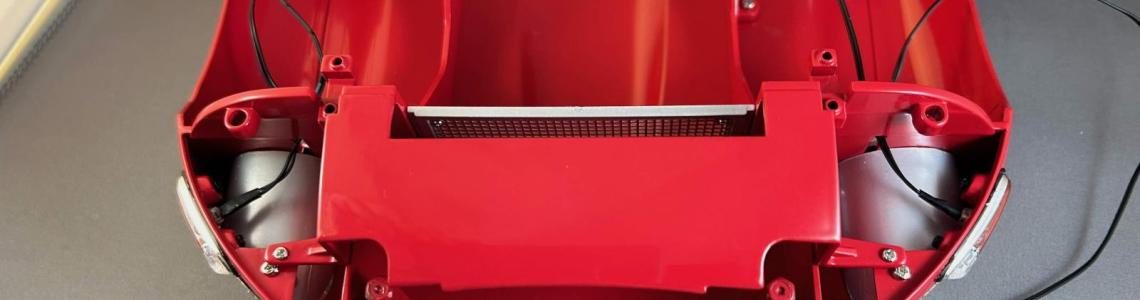

Pack 10 begins by finishing off the hood and fenders. First the “valances” (inner wheel wells?) are installed on the underside of each fender, and then the headlight covers and chrome trim are installed. This is, I believe, the first place that the instructions actually call for some white glue to hold the covers to the trim. I used Model Master clear parts cement, but any type of white glue would do the job so long as it is used sparingly. Once the covers are installed in the trim, the trim snaps into the fenders. Following this, the stone guard is assembled and installed to the underside of the hood, and the front underpanel is installed.

The focus of this pack then switches to the assembly of the final wheel and tire. By this time, I’d become an old hand at the process, so I had no real issues. It still took me 2 hours to complete the wheel, so while I felt more comfortable with the process, it didn’t improve my time any. Once the wheel was completed, it was installed on the rear floor assembly.

The final part of pack 10 involves installing the hinges and latch on the boot cover (trunk lid). After the stress of the wheel build, this was a pleasant and simple process.

Pack 11 begins with the assembly of the luggage rack. This is the only optional part of the entire build, and while I opted not to install the rack on the trunk lid, I did build it. The rack itself is a simple assembly of 3 pieces held together with two screws. Installing it on the trunk lid requires you to drill six holes through the trunk lid. The locations for the holes are marked on the underside of the lid. I personally did not trust myself to drill the holes without messing up the finish on the trunk lid.

Once the luggage rack has been dealt with, the trunk lid is fitted to the body. I should point out that the box for Pack 11 is huge compared to the rest of the packs, and that is because it contains the body. This one large hunk of metal packed in a foam cube, and the finish on mine was excellent. If you have not already put a protective surface out on your work area, now is the time. From here on in, almost every stage of the instructions will tell you to do this, because you will almost always be working on the body, and you do not want to scratch the finish.

Once the trunk lid is attached to the body, the next step is to attach the interior trim to the windshield pillars. While the trim is attached to the body at the bottom with screws, they recommend using a bit of super glue to keep the top of the trim flush against the pillar.

The next stage has us attaching some mounting brackets to the body and the firewall in preparation for mating those two assemblies. They suggest that you might want to leave one of the brackets off for now as it interferes with the mounting the antenna in a later step. I opted to go ahead and install it now, as it would be easier to remove and reinstall it later than to try to keep track of a small bracket and screw until they were needed.

This stage also has us install the hub caps onto the wheels. The hub caps are very cleverly held in place with magnets, which makes installation quite simple. The trick is that there are different hub caps for the right and left sides. Also, there are only 3 hub caps provided in this pack. The fourth was provided way back in Pack 3 for some reason, so you will need to go find it.

Next comes the installation of the windshield frame and windshield. This is a rather tricky ordeal, as the instructions call for the use of a rubber mallet to pound the frame down into position. I did not have a mallet, so instead I used a lightweight hammer and folded up the microfiber cloth that came with the kit to provide some padding between the hammer and the frame. This is all required to force a small bracket at the bottom of each side of the frame down into a slot in the body. After a great deal of rather tentative pounding, I was able to get one side of the frame to go all the way in, but the other side remained just slightly raised. If I had it to do over, I would first try to file some of the paint from inside the slot in the body into which the bracket of the frame needs to fit. This probably would have made the whole process go more smoothly. Also, my work surface was not particularly solid, so some of the force from the hammer blows was being dissipated into making my table bounce up and down.

The next few steps have you attaching the antenna, the windshield wipers, and the fuel filler door to the body. To attach the antenna, you’ll need to remove that mounting bracket I mentioned earlier, as it blocks access to the screw holding the antenna in place. Also, I had trouble installing the hinge cover of the fuel filler door. I eventually found that putting the fuel filler door into the open position in allowed the hinge cover to go in place properly. The windshield wipers were also slightly fussy about going into place properly, but I was able to get them to cooperate in the end.

Next comes the installation of the rear-view mirror. The mirror itself is attached to a post that runs from the top to the bottom of the windshield frame. It comes with a stick-on chrome surface for the mirror face, which went on quite nicely. The instructions would have you attach to the mirror to the post (which absolutely requires some white glue to stay in place), and then attach the post to the windshield. But I found that the mirror tended to be in the way, and I actually knocked it off on my first attempt; so, I left it off until I had the post in place. The top of the post fits into a hole in the top of the windshield frame, while the bottom wedges into a slot in the body at the bottom of the frame. The post doesn’t flex much, so I found the best way to install it was to put it into the hole at the top, then wedge the bottom of the pole into the window frame off to one side and slide it over into the slot. Once the post was in place, I reinstalled the mirror (with glue, of course).

The final stage of Pack 11 involves installing the back wall of the interior to the interior floor. I found the fit of this piece to be a tiny bit fussy, but with a little effort it went into place.

It took me 3 hours to complete Pack 10, and another 2.5 hours for Pack 11, bringing my total time spent to 31 hours so far. This was pretty much in line my expectations based on the earlier stages of the kit. The next (and final) pack will pretty involved, as we will be mating up all our earlier sub-assemblies into the final product. Stay tuned!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews