Harley Davidson FLSTFB Fat Boy Lo, Part 2 - Assembly

Part 1 of the Tamiya Fat Boy review describes the background of the Fat Boy motorcycle and the Tamiya kit contents. This Part 2 Review describes the assembly of the Tamiya Fat Boy kit.

This is a fantastic kit! Not only is the Harley Davidson Fat Boy an iconic motorcycle, assembling this kit is one of the best modeling experiences I've ever had! The engineering and detail is phenomenal, the fit and finish of the parts are excellent, and the assembly, while complicated, goes together very well. The kit is a joy to build!

Background

The Harley Davidson Fat Boy is the latest in Tamiya’s series of 1/6 scale motorcycle kits. This is a large, multimedia kit with plastic, metal, rubber, diecast, and photoetch parts. This review also includes Tamiya’s Harley-Davidson Fat Boy Lo Detail Up Parts Set, item 12655 (MSRP $96.00).

The kit features a range of moving parts – working kickstand, brake pedal, gear shift, wheels rotate, front fork turns, drive belt turns with rear wheel, brake & clutch levers, front shocks, rear swing arm, etc.

Fat Boy assembly

Modelers should identify the country for which they will model the kit, for as there are a few variances as noted in the instructions. There are versions for the USA, Japan, UK, Germany, Spain, France & Italy.

The kit is molded mostly in black plastic with a semi gloss finish. The chrome parts are matt and shiny, and have beautiful finishes. Tamiya does a nice job locating the sprue connections on the backside of parts to protect the exposed face, particularly with the chrome-plated pieces. Mold seam lines and sprue connections on the chrome pieces are cleverly placed to avoid damaging the exposed finish, Only a few areas required touch-up of the chrome finish.

Tamiya uses about every type of fastener in modeling for this kit: solvent cement, double-stick tape, super glue, screws, bolts, poly caps, and compression fits. The kit is multimedia with plastic, photoetch, diecast, rubber, resin, and foam tire inserts.

Assembly begins in steps 1 through 5 with the lower end of the engine and transmission. In step 2 the two halves of the engine transmission unit are cemented together including the lower end of the cylinder stud bolts. The two engine halves can be cemented together and then painted to allow cleaning up the glue joint. Tamiya provides detailed paint instructions in each of the assembly steps to allow painting as the kit progresses.

The bolts to be installed in step 2, parts D20, need to have the chrome plating removed from the area to be cemented. Tamiya provides many reminders to remove the plating from surfaces to be cemented. I scraped the plating off of the backside of the bolts, D20, prior to removing them from the sprue and then clipped off the remaining sprue connection point with an X-Acto blade.

Step number 2 includes the first use of the Detail Up Parts Set with photoetch parts for the bike and engine serial numbers, and the engine and transmission numbers. The photoetch parts have a shiny metal finish with much nicer detail than the kit’s decals. The photoetch parts are the ‘connector-less’ type on a backer sheet so there are no connections to clean up. Very nice.

Poly caps are used to fasten the oil filter, part C18. Apparently to allow removal of the filter when the engine oil needs to be changed.

Step number 3 includes the first use of screw fasteners. There is a section of sprue A that can be used to practice installing screws. Be careful not to over-tighten the screws as it will strip out the threads! Tamiya has separated the screws & bolts into packages that help with identifying the correct size fastener. The instructions also have a handy size chart with each step to aid in selecting the right fastener. Very thoughtful.

Step 3 also includes the installation of several pieces of vinyl tubing, which are used throughout the assembly for various pipes and cables. Tamiya provides a handy length guide for the tubing pieces to be cut on the edges of the instruction sheet. Labeling the loose end of the tubing with a piece of tape and the tube letter helps keep them organized.

In step number 5, the appropriate part F6 or F9 should be used depending upon the country selected for modeling the motorcycle. I applied decal #2 to the black semi gloss paint on part F9 and it silvered badly. A gloss coat should be used over to improve adhesion of the decals. The decals are quite thin, have nice detail, react well to MicroSol and are generally easy to install.

In this step Tamiya also uses double-sided tape has an attachment technique. Each step using double stick tape has a template for the correct size of the tape. The tape seemed strong enough and I had no adhesion problems.

Step 6 begins the assembly of the Fat Boys frame. Don't forget to entrap the nuts parts MB4 and MB6 in the correct locations for attaching parts later on. Also in this step more of the Detail Up Parts are used.

Steps 6 through 13 build the frame and set the lower part of the engine. I glued the frame section parts A2 and A18 together and then scraped the seams prior to painting. In step six and seven there are again options for the warning labels down the frame depending upon the country the bike is being modeled for. Steps 8 through 11 install the oil tank and front hydraulic control unit.

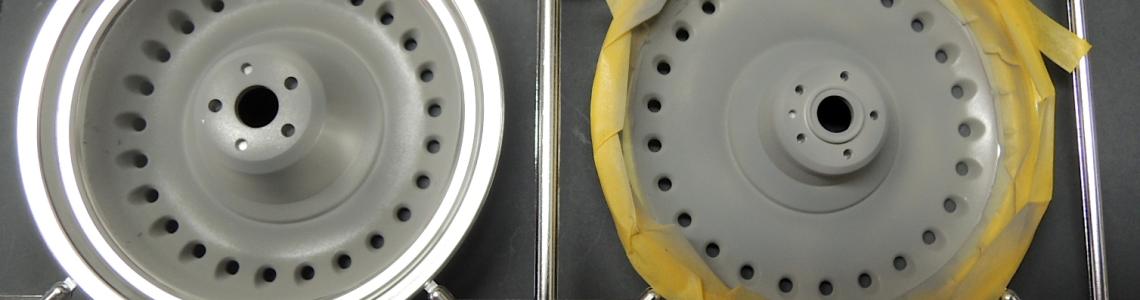

Step 14 assembles the rear wheel and brake rotor. The Fat Boy version of the Blake has a semi gloss black finish for the internal circles of the front and rear wheels. Tamiya has molded the wheels in one chrome-plated piece, which requires painting the inner circles in a semi gloss black. This is very difficult to mask off the inner portion of the chrome wheel. I tried masking and I tried painting it by hand. The chrome surface requires priming for the semi gloss black paint to adhere. I think it would have been much easier if Tamiya had molded the inner wheel in a black plastic and the outer wheel as a separate ring that is chrome plated. This would allow painting before assembling the two portions of the wheel.

This step also installs the brake rotor, and there is an optional rotor in the Detail Up Parts Set. The optional Detail Up rotor is metal, much sharper in detail, and has nice detail of the surface contacted by the brake caliper. The Detail Up rotors add considerable quality to the kit in comparison to the plastic part.

Step 15 installs the tires, drive sprocket, and rear tire on the rear wheel. Tamiya does a better job with the drive sprocket by separating the chrome ring from the inner sprocket, which gets painted flat black. This makes it a lot easier to paint the sprocket and then install the chrome ring. Tamiya provides a length of foam plastic to be inserted in the tire so that he keeps its shape. I sanded the tire with a motor tool to remove the center seam and remove the showroom shine from the tire. The tires and wheels look very sharp when assembled. The drive sprocket assembles to the rear wheel with three bolts. Unfortunately these bolts have a different appearance then the two molded on bolts. I would think Tamiya would have used all bolts so they would look similar.

Step 16 installs the rear tire and drive belt onto the swing arm. Notice that the drive Belt installs through the arm of the swing arm and the lower part of the belt installs underneath the guard part O2 installed in step 13. This is not entirely clear in the instructions.

Steps 17 through 20 installed the rear wheel and swing arm to the chassis. In step 18 the shock absorbers are assembled with a spring, which allows them to compress. In step number 22, Tamiya provides the order of steps to install the swing arm to the chassis. The shock absorbers are fastened first, then the bolts for the swing arm, then the cross brace on the underside of the frame.

Steps 21 and 22 install the chain case. In step 21, part O1 is provided in black molded plastic but is to be chrome painted. Could just as easily been plated. In step 22 decals are installed on the outside chain case cover. The instructions show decals for the bolts on the cover, part F11. I chose to paint these with chrome paint rather than trying to get the decals to conform to the bolt heads. Also part F11 is provided in chrome but noted to be painted black so it could just as well been molded in black plastic.

Steps 24, 25, 26 and 27 install the cylinders and cylinder heads to the engine. These are nicely made up of layers to create the depth of the cooling fins on the cylinders and heads. Tamiya thoughtfully numbers each of the parts on the underside to keep them in the proper order. Carefully remove the sprue connection points from the cooling fins as these are painted with chrome paint and will be highly visible. I painted the cooling fans flat black, assembled each one, and then used Model Master chrome paint on the edges, which worked okay. Another option would be to paint each layer black and paint the edges chrome prior to assembly. Another option would be to plate the fins with chrome paint and then paint the top and bottom surfaces flat black. The flat black and chrome edge cooling fins look quite impressive when assembled.

Steps 29 through 30 attach the exhaust pipes and mufflers using the heavy cast mufflers from the Detail Up Kit. Photoetch is provided for the muffler straps.

Step 31 installs the brake pedal, which movies realistically with a spring return. The screw identified as MP3 should be MF3.

Steps 33 and 34 install the air cleaner, right footrest, spark plugs, and horn.

Steps 35 through 39 assemble the front fork and headlights. A very straightforward and nicely engineered assembly. The forks have springs so the shock absorbers actually work.

Step 43 assembles the gas tank and Harley Davidson emblems. Take care and use MicroSol to install the Harley Davidson decals #1 to the emblems. I tore one of the decals and had to paint the background.

Step 47 attaches the rear fender. Tamiya again uses a nice technique of placing the sprue connection points on the backside of parts so they don't damage the front face. Also many of the parts use concealed fasteners to avoid damaging the finish.

Steps 48 and 49 attaches the seats, which are a soft rubber material, are beautifully cast, and very realistic when completed.

Step 50, 51 and 52 assemble and install the turn signals, brake and clutch levers, rear view mirrors, and handlebars. Step 52 also completes the wiring for the handlebars and front end of the motorcycle. I could not tell where tubing K is terminated. It appears this is a speedometer cable and the location for the loose end does not show in the instructions,

Step 53 installs the taillights, 54 installs the license plate and frame, depending upon the country chosen, and the last step 55, places the bike on the stand. The painting and marking options show locations for a few more decals and the decals for the various license plates.

Summary

This is an expensive kit, but can be found for less online, and is still well worth the cost. The Detail Up Parts Set adds nice detail to the kit, especially in the brake rotors. For the cost of the main kit it would be nice if Tamiya just included the Detail Up Set rather than it being extra.

In summary this is an excellent kit of an iconic motorcycle. The engineering and detail of the kit is phenomenal, the fit of parts is excellent, and the resulting model is a beautiful replica of the Harley Davidson Fat Boy. This is a fantastic kit that Tamiya has developed and they should be congratulated for a fine effort!

Many thanks to Tamiya for providing the review sample to IPMS so I got the chance to build the kit. Again, thanks to the great I PMS review crew for the opportunity to build this great kit!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews