SH-3D Sea King Interior Self-Adhesive Color Photo Etched Set

Introduction

The Sikorsky Sea King helicopter was developed in the late 1950s for the US Navy’s growing anti-submarine warfare role. Becoming operational in 1961, the Sea King would serve with the US Navy until 2006, and continues in service with other operators to this day. Over its lifetime, the Sea King would spawn multiple variants and revisions. This included versions to meet USAF and USCG roles, such as the well known HH-3E Jolly Green Giant combat search-and-rescue helicopters. Additionally, licensed-built versions of the Sea King were made by Mitsubishi, Agusta, and Westland. The British-built Westland Sea King variants differ in quite a few points from the Sikorsky-built Sea Kings, and are the basis for Cyber-Hobby’s 1/72 Sea King kits.

Cyber-Hobby has released a wide array of 1/72 Sea King helicopter variants in the last two years, and Eduard has met these releases with several photo etched (PE) detail sets. Most recently, Eduard has developed interior and exterior PE sets for Cyber-Hobby’s SH-3D version of the Sea King. This review will cover the recently released interior PE set, while the exterior set will be covered in a separate, forthcoming review. The base kit used for this review, Cyber-Hobby’s SH-3D Sea King, has previously been covered on the IPMS/USA review site: http://web.ipmsusa3.org/content/sh-3d-sea-king

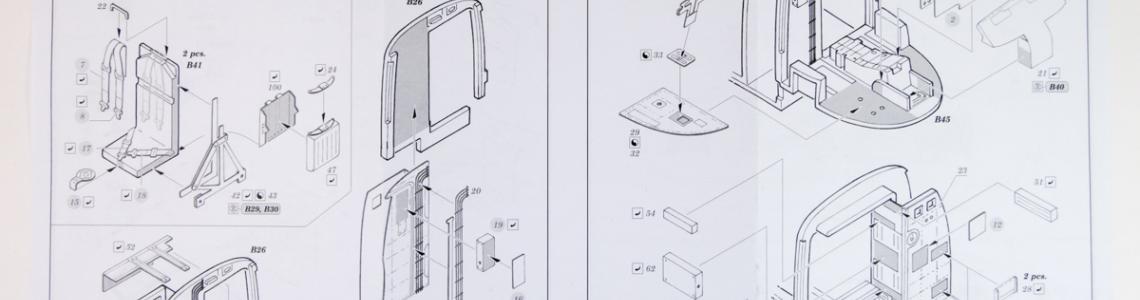

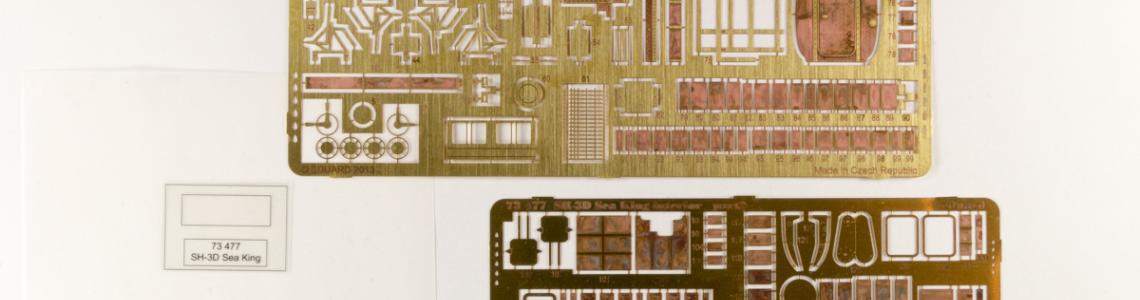

Eduard’s SH-3D Sea King interior self-adhesive color PE set consists of three frets of PE, one in full color and the other two in raw brass, a small sheet of clear film, and a detailed instruction sheet. As usual, the black and white instructions are available in color on Eduard’s website.

Cargo Bay Assembly

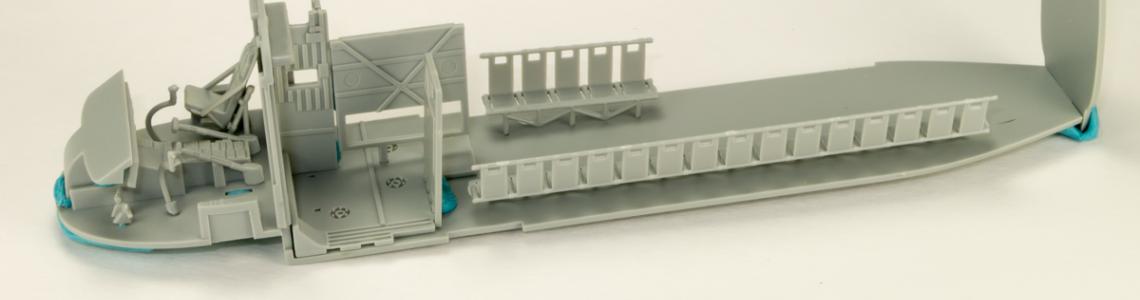

While the exterior of the Cyber-Hobby’s Sea King will need a great deal of conversion work to replicate a US Navy SH-3D, the basic interior accuracy is quickly improved by Eduard’s PE set. The Sea King’s interior is comprised of the cockpit and the “cargo bay” area. The kit’s cargo bay features parts for several large partitions and some rather tiny looking seats. The Navy SH-3D seems to be devoid of any major partitions in the cargo bay, with only a minor “broom closet” partition, directly behind the cockpit to house various flight control systems.

Eduard’s PE eliminates all of the cargo bay parts by providing a detailed floor overlay, PE part 115, to cover all of the various mounting holes in the kit’s floor, part B45. The flight control broom closet is replaced with a detailed, folded piece of PE attached to the cockpit partition, kit part B26. When building the kit without the PE set, a hole needs to be opened in the kit’s floor to allow the sonar well, part A9, to pass through. The PE floor overlay has a hole in the middle to line up with the floor’s hole. Careful fitting of the PE overlay needs to be done to ensure that the upper portion of the sonar well can also pass through the PE overlay without binding. This protrusion of the sonar well into the cargo bay is to hold the sonar dipper, part A8, fully in the sonar well. The Eduard PE set provides a detailed cover around this protrusion, PE part 58, so I chose to simply cut off the protrusion on the sonar well, part A9. This left the well flush to the bottom of the floor, and created a hole extending between the well and the cargo bay. Later, I mounted the sonar dipper, part A8, to a cable and attached this to the PE sonar winch inside the cargo bay. This allowed the dipper to hang in the sonar well surrounded by the replacement PE cover, part 58.

The PE sonar winch is the only replacement equipment provided for the cargo bay. It’s a complicated construction of multiple folded layers of PE parts (and a few modeler-supplied bits of round plastic) to create three-dimensional cable reels, supports arms, and floor mounts. It’s very impressive looking, especially once it has been painted, and seems to match photos and diagrams of the real sonar winch. The one major issue is that it, along with the cover and opening to the sonar well, seems to always be enclosed by a “tent” of heavy covers. I’m not sure their purpose, but these covers may be needed to shield the equipment from the environment, or even the crew from the equipment. Additionally, the cargo bays of the sonar-equipped Sea Kings have workstations, seats for the sonar operators, and a great deal of additional electronic equipment. Even the non-sonar equipped aircraft seem to have a third fixed seat in the cargo bay, directly behind the broom closet. All of this is to say, the Eduard PE set is a good and accurate base to work from, but you’ll need to do a great deal of scratchbuilding to create and fill an accurate interior.

The remainder of the PE for the cargo bay is used to add detail to the inside walls of the fuselage halves. The kit’s fuselage has some nice, basic ribbing. The PE enhancements consist of about 75 individual panels that fill the areas between the kit’s ribbing, along with a single overlay panel for the rear bulkhead, kit part B27. Most of the PE panels feature subtle raised riveting, while a few add some additional raised ribbing. The panels all fit perfectly, with the exceptions of PE part 89 which required a slight trim and PE parts 93 and 94 which had their locations swapped in the instructions. Once installed and painted, the panels look like they were molded into the plastic and offer a subtle bit of detail. There are also PE surrounds for the three cargo bay windows (one of which shouldn’t exist on an SH-3D) that give them some extra frame detail, and look great when painted safety yellow.

Cockpit Assembly

Eduard’s PE set really helps to bring the cockpit to life. Nearly every part and surface is enhanced. All of the instrument panels receive color PE, and color seatbelts and placards are included as well. It’s a very ambitious refit, and the effort will pay off as the cockpit is easily visible through the large windows. It’s important to consider the order in which the cockpit is assembled, as the floor and walls will need to be painted before any of the color PE parts are used. I would not recommend masking the color PE parts as I have had portions of the color printing chip or pull off of the PE’s surface when using tape or blue tack for masking. The most notable assembly order issue is that the cockpit partition, kit part B26, must be fixed into place before the cockpit floor overlay, PE part 52, is applied. Also, while building the cockpit, be sure to fix Cyber-Hobby’s mistaken placement of the collective lever, part B32, to the right side of the co-pilot’s seat; it should in fact be to the left side of the seat.

The cockpit floor is covered with PE overlay panels that depict rivets and the seat tracks. Thin replacement rudder pedals fit onto the floor overlays. As mentioned before, the cockpit partition is overlayed with folded PE part 23, which creates a new avionics broom closet and adds detail to the cockpit wall. Attached to this part are multiple folded PE avionics boxes, some visible wiring made from PE, and a few color panels.

The seats are entirely reworked with PE. New frames are included, which require removal of some modeled in braces on the seats, along with color PE seatbelts and equipment boxes that fit behind the seats. The entire center console is covered by a folded PE assembly. After painting, this new cover will be topped with a color PE instrument panel. The main instrument panel, kit part B44, and the instrument panel shroud, kit part B40, are replaced entirely with PE parts. The main instrument panel is constructed from self-adhesive PE parts 1 and 2. The shroud is replaced with PE part 21, which will need to be folded and bent into shape. The shroud has to fit below the front of the fuselage halves, so test fitting is a must to achieve the proper fit. As the PE main instrument panel is much thinner than the kit part it replaced, a great deal of care will be needed to fit it into place. Although the part is self-adhesive, superglue will need to be used as the adhesive backing has nothing to attach to. There is a wonderful opportunity to superdetail the back side of this thin PE instrument panel, which can be viewed from the windows at the lower edge of the cockpit.

The final bits of PE for the interior include a color overhead instrument panel overlay, frames for the interior of the cockpit side windows, and interior trim for the upper portion of the two-piece, port-side boarding door, kit part B21. The crew boarding ladder on the lower portion of the port-side door is available in PE in Eduard’s Exterior SH-3D set for use in the open position. The kit also includes the boarding ladder detail, but also only for display in the open position. If you’d like to add this detail to your closed door, you’ll have to do a bit of work on the kit parts, or grab Eduard’s Exterior SH-3D set and modify it for use in the closed position.

Painting

The photo etched parts look pretty impressive when installed, but really come to life when they “disappear” under paint. Truly, they seem as if they’re molded in, and it would be somewhat challenging to pick out all of the PE bits if you didn’t know where they were located. I think this is about the highest praise for a PE set: seamlessness. I used Model Master Acryl Dark Gull Grey for the interior color. I then added some additional coats of the color, first darkened with a few drops of Vallejo Wash for Grey & Dark Vehicles, and then lightened with Model Master Flat White, to add some high- and low-lights. I sealed it all with Model Master Flat Clear. It was only after this stage that I added the color PE parts.

Conclusion

With the painting complete and the color PE added, the interior was ready to be sealed inside the fuselage and the remainder of the build completed. As I mentioned, I will be reviewing the Eduard SH-3D Exterior in the near future, which will show the model in its final form. As for the interior set, I was very pleased. There is a lot of PE included in this set, but there were almost no superfluous parts. The sonar winch may not be useful for every modeler, but it can add a bit of interest to an otherwise empty space, and it’s really a great launching point for superdetailing the cargo bay. As with most PE, there is a higher degree of difficulty in using these parts. Some of the small boxes will require precision and experience to fold and assemble cleanly. The winch is also an extremely intricate assemblage of PE parts; remember that it’s flat in the package. If you’ve worked with PE in the past, this set will be no trouble for you. If you’re new to PE, you might want to try a slightly smaller project to cut your teeth on. Still, I highly recommend this set, it adds a real pop to the inside of the cargo bay, and will really shine behind the large greenhouse of the cockpit.

My many thanks to Eduard for supplying this photo etched set, and my thanks to IPMS/USA for the chance to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews