Photoetch for MiG-29UB Izdelye 9.51

This set is designed to be used on the MiG-29UB kit released by Trumpeter last year. It includes not only the full color set SS593 to upgrade the front and rear cockpits and both ejection seats, but also a second brass fret of external details. The detail on both sets is outstanding and the color set is beautifully printed. Based on the colors used for the cockpit side consoles, it looks like Eduard used a later build MiG-29UB as the side consoles and instrument panels are in a medium grey, not the bright blue-green color seen on many other Russian/Soviet aircraft. Unfortunately, the instructions do not include any painting references for the cockpit or other kit parts, so you must do your own matching. To my eye, the grey looked pretty close to the Testors Dark Ghost Grey (FS 36320) I recently used on a F/A-18E build, so I used this color as the base interior color.

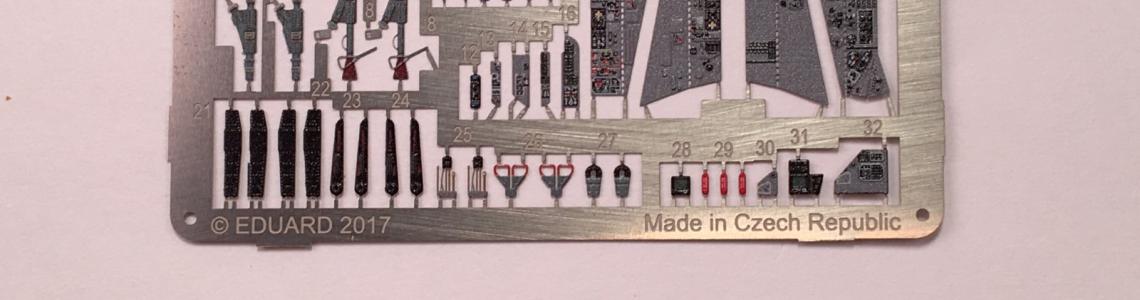

The set is pretty comprehensive, there are 7 color etch parts just for the instrument panel in the front seat. The set also includes some of the smallest etch parts I have used for a while as there is a piece for the face of each control stick depicting all of the buttons and switches on the control stick.

The instructions bounce back and forth between installation of the color fret and the brass fret. For example they start out with the ejection seats with the color etch and then go to the installation of the afterburner injector from the brass sheet. I strongly recommend you take a couple of minutes reviewing the instructions for the etch set and the kit instructions as the order set forth in Eduard’s instructions does not make sense for some of the parts, for example on page 1, they show the installation of the canopy seals and mirrors on the main canopy – I did this after the model was painted and decaled as I tacked the canopy in place in order to paint the camouflage.

With respect to the ejection seats, you will need to carve or sand off the molded-on seat harnesses, the hinge points for the arm rests and the molded portions of what appears to be leg restraints, as all of these are to be replaced with etched parts. Be sure to check your references as to the colors of the K-36 ejection seat for the aircraft you are building. I painted mine Tamiya NATO Black and I used Tamiya Flat Black to pick out details and highlights and Testors Gloss Black for the seat cushion and the headrest. The etch set includes a full set of harnesses, the butterfly shaped ejection handle, the G-suit and oxygen connections, and what appears to be leg restraints for each seat. The instructions are unclear what to do with part #2, the lap belts, as they just indicate that you need to fold these and install them. If you simply fold the belts at the break, you will end up with an unpainted side facing up. In reality you either need to twist the shorter part of the belt 180 degrees before folding so that the painted side ends up facing up, or cut the belt at the break, flip the short belt over and glue it on top of the longer section. I opted for the second approach as it allowed me to square off the ends of each belt and then match them up. I recommend only putting glue where the two belts match up at the squared off end, not at the ends with the buckles as these belts eventually get bent down over the front of the seats and I discovered that the ones where I glued the entire length of the top belt were much more difficult to bend down over the front of the seat. Be careful where you install parts 21 and 22 as if they are too close together, you will not be able to get them around the control stick when you go to install the seats in the cockpit. As only one side of the etch is painted, once these parts are bent, you will need to paint unpainted sides of the two ends otherwise the brass color will show.

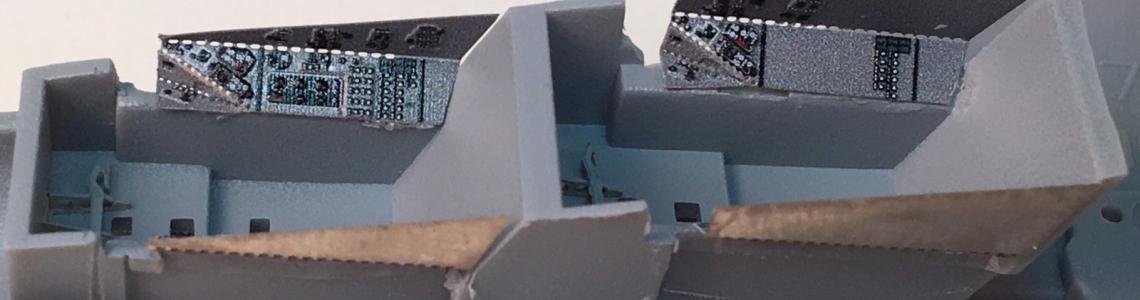

The next major assembly step relates to the two instrument panels. The instructions direct you to remove the raised or engraved details on both the front and rear instrument panels to prepare them for the photo-etch parts. I sanded down most of the surfaces as instructed, except for where the main instrument clusters go as these are represented be recessed dials on the kit parts, so I simply attached the black back-plate for each main instrument panel over the kit holes. Take your time in lining up the front plate of the instrument panel so that the instruments show through the open holes. I set the front of the panel over the back plate and once the instruments were lined up, I touched a little thin superglue to the edges of the panels to attach them to each other and to avoid accidently ending up with a blob of superglue in the middle of a dial. Part 31 in the rear cockpit appears to be a shroud around either the infrared tracker display screen or a CRT, so the top and right side need to be bent in to form the shield. However, since Eduard’s Zoom sets only have color printed on one side, once the bends are made, you will need to paint the outsides of the shroud black to match the rest of this panel. I found the fit of all the instrument panel etch parts to be outstanding.

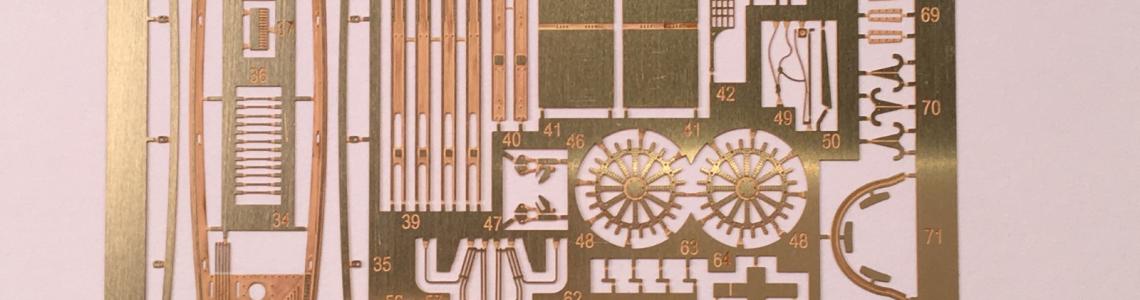

Again, I deviated from the assembly sequence as the instructions direct you to install the brass etch on the landing gear struts as the same time as you are working on the cockpit. However in the kit instructions, at this stage the gear wells have not even been installed. Once again, I deferred this step to much later in the build.

The next step is the installation of the new cockpit consoles. Eduard’s design is very ingenious as they have included not only the side consoles, but also the cockpit sidewalls as a single etched part for each side of the two cockpits. The first step is to remove the red marked areas from the kit cockpit tub. I recommend removing a little more than they show for the right hand consoles as there is an interesting bend at the front of each of these consoles. I also recommend attaching the cockpit tub to the kit bottom fuselage before installing any of the new side panels as the sidewalls need to be bent so as to fit inside and match the contours of the upper fuselage, or you will not be able to attach the bottom fuselage to the upper fuselage. You will be doing a lot of test fitting of the top and bottom fuselage halves while installing the console parts.

There are very visible dashed lines in each console part showing where that part is to be bent. When you get the bend correct, use superglue to attach the etched console to the cockpit tub, making sure that the inside edge is flush with the tub. If they are not and the etch hangs over into the cockpit hole, the ejection seats will not fit – trust me, it is no fun when this happens! Again, let the superglue cure really hard before fiddling with the side consoles as the actual gluing surface for each side console is pretty narrow.

The brass fret includes replacements for the intake screens/ramps that are so visible on the Fulcrum. The bend points are well marked, but take your time making your bends to insure the screens will fit inside the intake and that both sides match. The brass fret also includes a piece for the cockpit rails and details for the turtleback behind the rear seat. The instructions have you installing several pieces of color etch (#29) at this time, but as you will need to paint the cockpit rails and the other brass parts, I recommend leaving these parts off until the end. The set includes brass details for the bottoms of three of the pylon types included in the kit. These are easily installed once you carve or sand off the attachment pins for the missiles.

The last page of the instructions is for the installation of the smaller detail parts on the exterior of the jet. Initially I misread where to install the aileron hinges and I glued them on top of the wings, fortunately, I realized my mistake before painting and I was able to move them to the underside of the wing – I forgot that the outer wings have the top and bottoms molded together with the top of the main wing. I installed all ten of the static discharge whips before painting and they really looked good! Unfortunately, I was not able to keep them installed during the painting process and in the end I knocked off 8 of the 10 I originally installed, plus all of the extras I had installed to replace the ones I broke off! These parts are very tiny and delicate, so install them absolutely last – and then do not handle the model!

Once the model had been painted and decaled, I went back and installed the etch on the landing gear legs. Take your time and ensure each section is securely attached before trying to bend the part around the gear leg. I left the bottoms unglued as they attach the gear stubs (parts D3 and D7) that you have to install in the main gear wells early in the build. I airbrushed the gear struts once the etch was installed, and then installed each strut in its respective gear bay. The loose etch was then wrapped around the gear stubs, superglued and painted.

The HUD was installed next using the clear acetate reflecting glass provided. The fit is tight as the HUD frame just barely fits under the windscreen bow. The final step was to go back to page 1 and install the canopy locking mechanism and rearview mirrors, then to carefully glue the canopy in the open position to show off all the marvelous detail that has been added.

While this set requires some preplanning and deviating from the instructions, once everything is installed, as shown in the photographs, the results are stunning! The set really makes the whole airplane come alive. Highly recommended!

Thank you to Eduard for the review sample and to IPMS-USA for letting me review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews