Mission Models Paint, Part 3 (Metallics)

This will be the third of a three-part review of Mission Models paints.

The Metallics

Mission Models has four new metallic paints, White Aluminum, Dark Aluminum, Duraluminum and Silver.

For this paint test I sprayed Mission White Primer after cleaning and degreasing the test surface. If you use gray or black primer you can get a variance of tonal quality for each of the metallic paints making them very versatile.

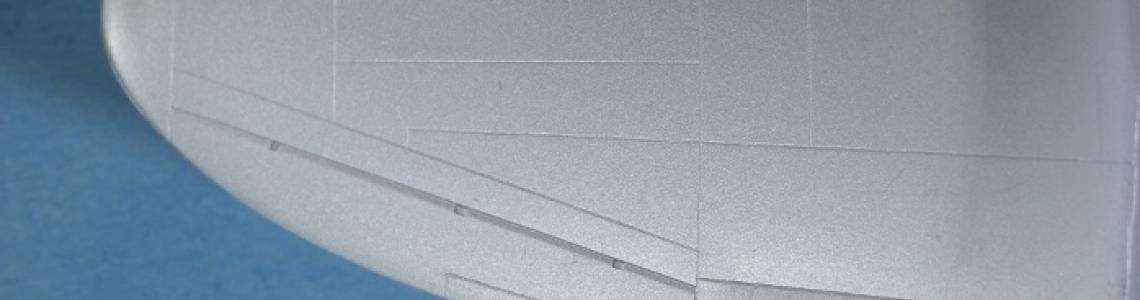

I decided to paint the White Aluminum and Dark Aluminum for this review. As you can see in the accompanying pictures the paints are very durable. Once laid down they will not pull up with masking tape and have a nice metallic sheen.

To test the ability of the paint to cover an area that’s been scratched or damaged, I started with a scuffed area and was able to almost cover the damage with 6 passes of the airbrush. What that means is that this metallic paint can be touched up after application as in the case a scratch, which is usually not the case for most acrylic metallics.

I used Tamiya tape to mask the area that had been repaired and when I pulled up the tape, no paint came with it. These paints are very durable and will stand up to decal setting solutions and enamel panel liners.

If you are doing a project with a Natural Metal Finish (NMF) with Acrylic paint, I recommend trying any of the Mission Metallics or Mission Chrome: I was not disappointed.

Gloss Black and Chrome

As with most “Chromes” Mission Chrome is to be sprayed over a coat of Gloss Black to attain the most mirror-like finish. For this purpose, Mission makes a Gloss Black Base as an undercoat for the Chrome that can be sprayed straight from the bottle using multiple light wet coats. You may have to spray several coats to get the gloss finish you’re looking for.

Its best to be sure that Gloss Black Base is completely dry before adding the next coat. In addition, Mission Black Base can be wet-buffed with 6000 grit (or greater) Micromesh between coats to get the smoothest finish possible.

When applying the Chrome, use light overlapping coats and wait for each to dry before adding the next. With successive passes the Chrome finish will start to develop. Continue adding light coats until you get the shine or mirror type reflection you’re looking for.

Mission Chrome can be tinted with a few drops of any of the Mission colors, Mission Red and Blue were each added to the Chrome and sprayed adjacent to straight Chrome. All three were sprayed over a coat of Mission Gloss Black Base. As can be seen in the pics, any Mission color can be added to the Chrome to get a myriad of Chromed colors.

I am not the best at taking pictures so I want to apologize to Mission Models Paints for the graininess of the photos of the Aluminum and Chrome finishes. Multiple lights and angles were tried but none of the pictures convey the very nice metallic sheen and good reflectivity of Mission Models Metallic paints.

I want to thank Mission Models and IPMS USA for the opportunity to review this product.

As always, with a new technique practice on a scrap piece before spraying on your project. I have found that there is a “sweet spot” to spraying the paints with regards to the distance and compressor setting.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews