Biplane - Wooden Jig Stand & Transport

I was fortunate enough to be able to attend the IPMS Nationals in Madison, WI, in July and was taken back by the variety of ‘specialist’ vendors providing their tools and techniques to the masses. One of the vendors that caught my eye was UMM-USA (Unique Master Models). UMM-USA is an on-line Store, importing and exporting kits, specialized modeling tools and supplies and consulting services. My main mission at the Nationals this year was to find a few tools I’ve been needing and UMM-USA had several I had been looking for.

Also at the convention, UMM-USA provided a few product review samples to the IPMS Reviewer Corp, so I was able to pick up this JHmodels Biplane-Wooden Jig Stand & Transport and a small hole reamer UMM-USA produces, for review (see the review titled: Micro Pyramid – Shanked Reamer RM (2.5mm))

JHmodels produces this biplane jig/holding fixture and variety of others like it and UMM-USA is one of the retailers. JHmodels products can be found on UMM-USA’s web site.

Jig Assembly

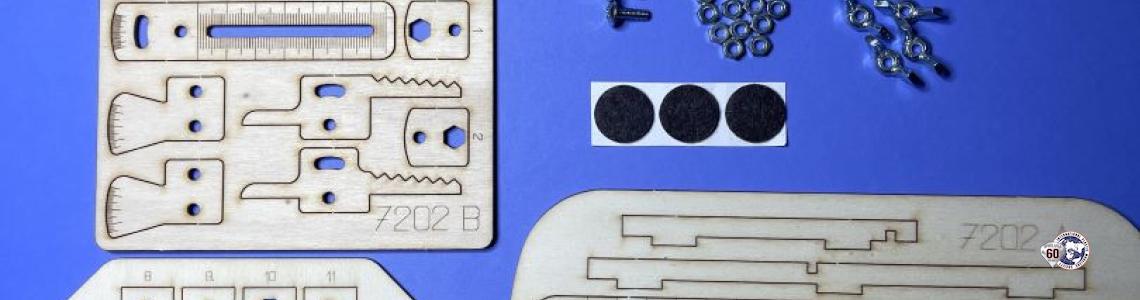

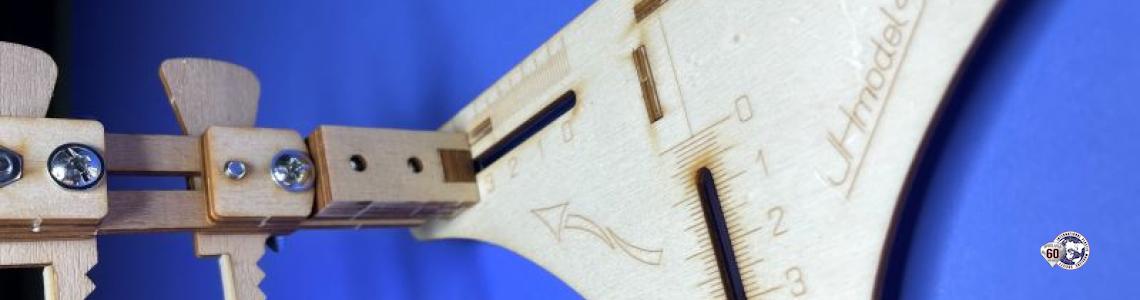

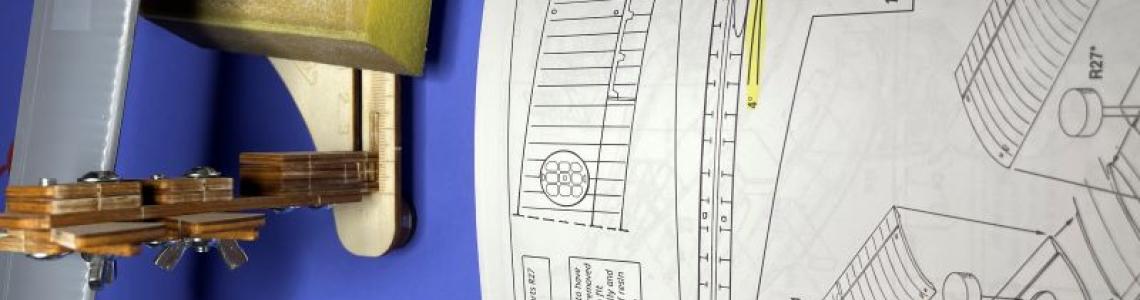

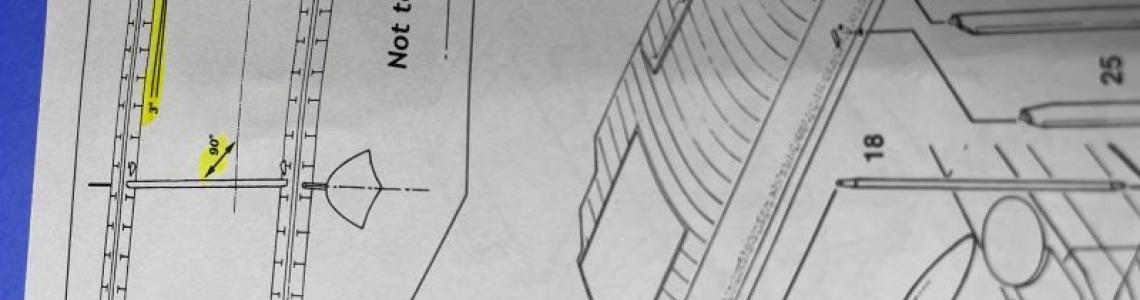

In the package you will find 52 laser-cut, wood parts on 3 ‘trees’ (excuse the pun), 3 different lengths of screws, hex nuts, wing nuts, rubber bands, 3 self-adhesive felt foot pads and a double-sided instruction sheet. The parts are easily pushed out of the trees and all that is needed is a little sanding to remove the tabs they were held in with. The parts are precisely laser-engraved with centimeter/millimeter (cm/mm) and angle (degree) scales.

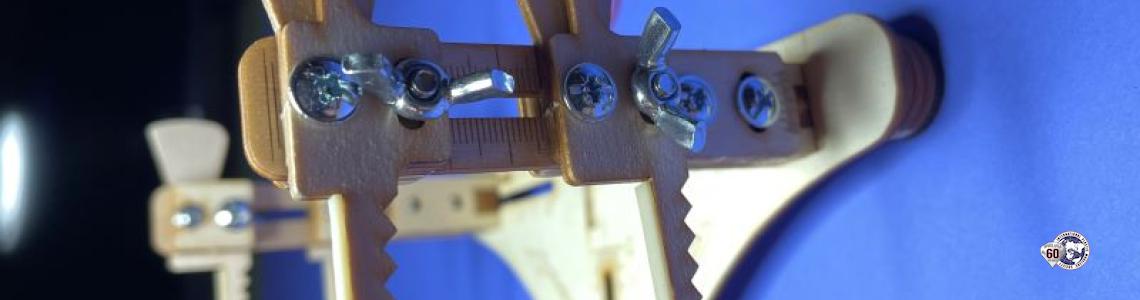

The trees are labeled 7202A, B and C. 7202A contains the base with stiffener parts, foot parts and the tail/body support. 7202B contains the vertical wing support parts and 7202C contains the parts for the 3 supports that attach to the vertical supports and tail support to the base. The wing and tail supports are shaped with a saw-tooth pattern on the bottom to hook the rubber bands around your model to hold it to the jig.

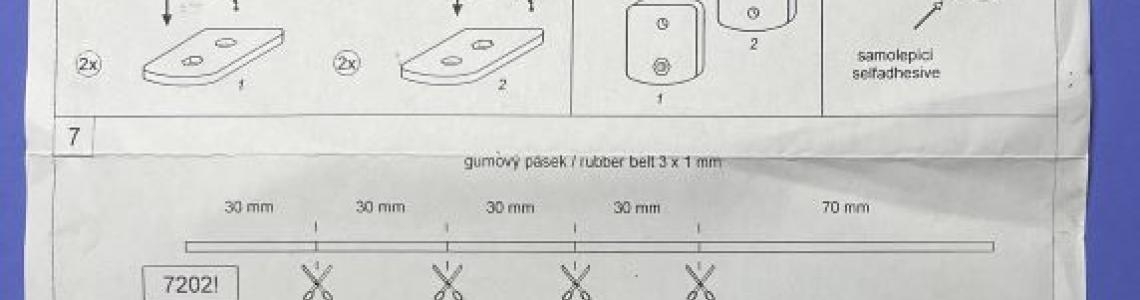

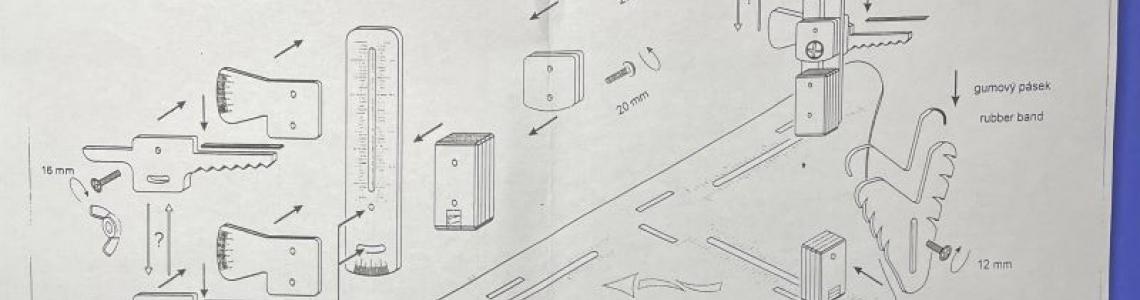

The jig building process is pretty straight forward but you’ll need to allow plenty of time for your choice of glue set up between assembly steps. Care needs to be taken to keep any glue out of the nut threads since applying extra torque to the nuts with the screws can break the nuts free from the plate holding them. As I was building up the subassemblies, I glued the hex nuts into their respective panels and sandwiched the lower support panels together into solid blocks (alignment is key in this step). The wing and tail/body supports aren’t glued since they are adjustable (good alignment is critical for ease of adjustment to fit your kit). The rubber belt provided is to be cut per the instructions and glued to the wing and tail/body supports as a pad between your model and the jig. This is a nice touch.

It's easiest to use a small screwdriver to tighten/loosen the screws but care must be taken to not overtighten or you can damage the wood. The surface friction of the wood parts is high so the screws and wing nuts just need to be snug to the surface of the wood parts.

There are two minor things to watch out for with the instructions and the part marking. Part numbers 2 and 3 on tree 7202C are swapped as they are represented in steps 1 and 2 on the instruction sheet but if you study the pictures, you can easily figure out which goes where in the correct sequence. The other thing is that trees 7202B and 7202C both have parts numbered 1 through 4 (they are not interchangeable), without any reference in the instructions as to which tree/parts to use. It is easy to keep track after you’ve understood the instruction sheet though.

Using the Jig

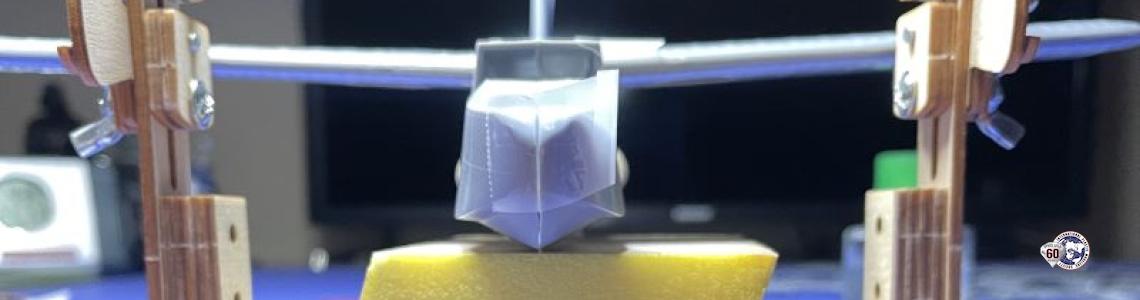

The key design feature of this jig is its flexibility to be positioned as needed to fit the model you’re working on. I decided to try this jig out with the 1/48 scale Classic Airframes, Supermarine Walrus biplane kit. Turns out this was an unintentional ‘worst-case’ kit choice to use with this jig because the Walrus wings are quite far apart due to the engine pod in between. The height between the wings at 1/48th scale was just outside the limits of this jig (less than 1/8th inch with the supports level) but I was able to adapt it to work ‘well-enough’ by manipulating the angles of the wing supports to get the glue on the struts to set up and hold. This jig should certainly help with holding any 1/72nd scale and most other 1/48th scale biplanes. The plastic of the Classic Airframes kit is quite soft so it was nice to be able to glue the struts, wrap rubber bands (loosely fit - barely stretched) around the wings and let the jig hold the kit still overnight to make sure the joints solidified properly. The upper wing dihedral in the photo looks exaggerated because of the nose-down pitch of the model in the jig but the struts are fit to both wings.

Conclusions

The JHmodels Biplane - Wooden jig stand & transport is a nice holding/building/transport fixture for 1/72nd and 1/48th scale biplanes. This jig is very flexible and helps with holding your kit in the right orientation and allows you to set up the wing alignment even with dihedral and offset leading edges. More experienced modelers will be able to adapt this jig to suit their needs but less experienced modelers can benefit from it as well.

“Thank you” to UMM USA for the review samples and thanks also to IPMS USA for giving me the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews