Albatros D.V

Brief History

The Albatros D.V was a fighter aircraft used by the Imperial German Air Service during World War I. The D.V was the final development of the Albatros D.I family, and the last Albatros fighter to see operational service. Despite its well-known shortcomings and general obsolescence, approximately 900 D.V and 1,612 D.Va aircraft were built before production halted in early 1918. The D.Va continued in operational service until the end of the war

In April 1917, Albatros received an order from the Inspektion der Fliegertruppen for an improved version of the D.III. The resulting D.V prototype flew later that month. The D.V closely resembled the D.III and used the same 170 hp engine. The most notable difference was a new, fully elliptical cross-section fuselage which was 32 kg (71 lb) lighter than the partially flat-sided fuselage of the earlier D.I through D.III designs. The new elliptical cross-section required an additional longeron on each side of the fuselage and the fin, rudder and tailplane initially remained unchanged from the D.III. The prototype D.V retained the standard rudder of the Johannisthal-built D.III but production examples used the enlarged rudder featured on D.IIIs built by Ostdeutsche Albatros Werke. The D.V also featured a larger spinner and ventral fin.

The D.V entered service in May 1917 and structural failures of the lower wing immediately occurred. In 2009, Guttman wrote that "Within the month Idflieg was doing belated stress testing and concluding, to its dismay, that the D V’s sesquiplane wing layout was even more vulnerable than that of its predecessor". The outboard sections of the D.V upper wing also suffered failures, requiring additional wire bracing, and the fuselage sometimes cracked during rough landings.

Against these problems, the D.V offered very little improvement in performance. Front line pilots were considerably dismayed and many preferred the older D.III; Manfred von Richthofen was particularly critical of the new aircraft. In a July 1917 letter, he described the D.V as "so obsolete and so ridiculously inferior to the English that one can't do anything with this aircraft". British tests of a captured D.V revealed that the aircraft was slow to manoeuvre, heavy on the controls and tiring to fly.

Box Art and Kit Contents

The box cover has a full color image of the black and white Albatros D.V flown by Bruno Loerzer. This is a most colorful version with the wing and tail lozenge pattern.

What's in the box? Two sprues of grey plastic packaged in a common clear, sealed bag. One small mask for the wheels and tires, and a larger masking sheet for striping the tail and fuselage (depending on the markings chosen). One PE fret with some parts pre-painted. One large decal sheet for the upper and lower wing lozenge markings and a second large sheet for the ribbing stripes, and lastly a sheet for the individual aircraft markings.

Instructions

The instructions are in a 16 page book form. A brief history of the aircraft is addressed on the cover page, with a sprue layout, paint colors, several exploded views of the assembly steps, masking guides, and four view color pages for the five aircraft that may be built from this kit. All the aircraft depicted are colorful and unique, making the decision on which one to model all the more challenging.

Construction

Before starting the assembly I needed to decide which aircraft I would model as I recognized the need to leave certain parts off the model until everything was painted and decaled. In addition if rigging is to be added to the build the rigging diagrams must be reviewed and small holes drilled at the appropriate locations

Cockpit

The cockpit is comprised of plastic, optional decals and PE parts with the constructions steps shown on pages 3 through 5. I painted the various parts and subassemblies as shown on the instructions. The PE seat belts have formed attachment tabs that need to be fasten into or onto other PE and plastic parts. Warm up your OptiVisor for this exercise, but in the end they really did work.

The rear cockpit bulkhead should be numbered B35 (it is shown as B36 in the instructions) did require some small styrene strips glued to its back surface and rear fuselage interior for a solid fit. Everything in the cockpit went together nice and tidy and tight, and again everything fit as advertised. The engine mounting platform is U-shaped and is fitted to the front cockpit bulkhead. Some care is required to have the part fit in place level.

Engine

The six cylinder Mercedes engine is comprised of five parts and the fit was fine. Once the engine was painted per the instructions it was fitted into the engine compartment floor opening and glued in place. I test fitted he two fuselage sides to confirm that the engine was in place nice and square, and was. Once the engine was glued in place the two fuselage halves were fitted together and solvent added to the join.

Armament

There are two small machine guns that are built from plastic and PE parts. Rather than use the perforated PE cooling jacket in place of the plastic parts, I formed the PE to wrap around the plastic. leaving a small gap in the PE on the bottom side, hoping it would not be visible on the finished model.

Fuselage

Once the fuselage is fitted and glued together holes should be drilled for the rigging and some PE parts are glued in place.

Landing Gear and Propeller

This is a delicate assembly and care and patience is in order here. I found the attachments between the struts and airfoil to be less than sturdy. I was challenged on how best to attach the parts for a solid connection with the fuselage. I decided to first gluing the struts to the fuselage and before the joint set up solid I fitted the airfoil in place and applied the solvent. The connections were tenuous at best. The wheels were glued in place last.

There ae two propellers and spinners included in the kit. The propeller was first painted with Tamiya XF-15 flesh, and when dry very thin slivers of Tamiya masking tape were applied randomly along the length of the blades, leave some of the paint exposed. I applied a coat of Tamiya earth. Once the paint was dried and the tape removed I brushed a thin coat of burnt sienna oil paint to stain the acrylic paint and simulate wood grain. This was allowed to dry for a few days and then a thin application of Tamiya clear orange was laid down.

Wings

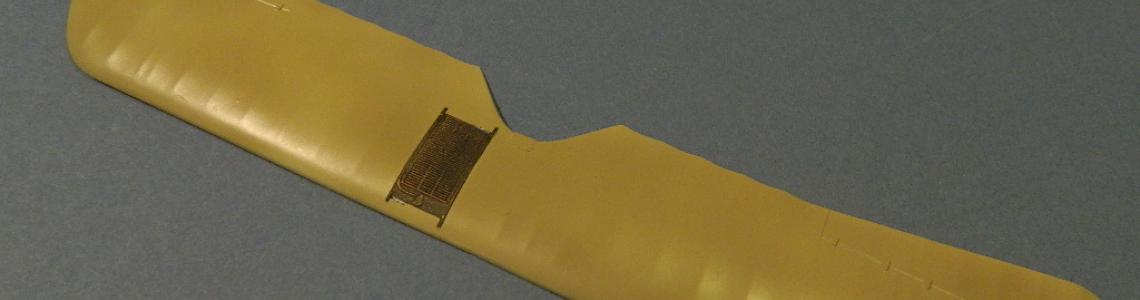

The top wing is a single part, but has several small PE elements that are shown fixed in place. The last detail in the instructions show the placement of tiny aileron hinges, top and bottom, plus multi folded PE hinge guards. The top wing would be left off until the model was painted and completely decaled.

The top wing is held in place by four struts attached to the fuselage and bottom with. Fitting the wing in place properly became a real chore. The fuselage and bottom wing strut locating openings must be over-drilled for a better mounting fit with the struts. The struts have undersized "pimples" that fit into the openings that are less than adequate for a solid fit. This was a challenge for me.

Painting

I left the top wing and struts off the model and planned to paint everthing separate before adding the decals. The engine and cockpit were closed off with tissue and tape before the model was painted with Tamiya fine white primer. I decide to finish the model based on the D.V flown by Erich Gurgenz, from Jasta 46, early 1918. The scheme looked to be challenging, utilizing painted surfaces, wood grain panels with lozenge camouflage on the wings. The left side of the illustrations shown the spinner and wheel hubs to be painted green, while the right side showed them as yellow, while the plan views indicated green. I went with yellow. Searches on the internet revealed several variations in the colors used.

First, the tail was painted white and the rudder was masked off. Next the tail assembly was painted yellow. The masks provided for the tail striping made the masking of the yellow portions less challenging.

The upper and lower wings were painted a light tan, and when dry were given two coats of Future as the gloss coat for the decals. The upper wing radiator was masked off and airbrushed Tamiya Rubber Black. When that was dry brass was dry-brushed over the black.

The front of the fuselage was painted a medium grey.

Masks

The kit comes with a large sheet of masks for the wheels, tail and fuselage stripes, making the maskinng efforts for the varous paint schemes a bit easier. Having painted the tail assembly yellow I found it a bit challenging to place the individual yellow masks. A good pair of jeweler's needle nose tweezers helped in this task. The masks are quite precise in length, wide and shape and will require a sharp eye and steady hand to align properly.

Decals

Be careful when removing the decals from the plastic bag. Eduard has sealed the bag with a narrow strip of adhesive on the closure flap which seemed to have a mind of its own: After opening the bag I slipped the lozenge decal out of the bag and the adhesive flap attached itself onto the decal surface and promptly removed part of the decal!

The decals should be applied to the wing surfaces, top and bottom, before installing the struts and rigging. I started with the upper wing, undersides. I first applied aileron decals D2 and E2 and allowed them to dry before attempting the larger, full under wing decal C2. Each decal was immersed in water and within a few seconds was ready to be slid onto the model's surface. Once the decals were properly located I used a paper toweling to blot the surplus water, and a Q-tip to squeegee the water from under the decal. I applied MicroSol to snuggle the decals in place. I cut decal C2 in half at the radiator opening to make this large decal a bit more manageable. This proved to be a good idea.

The upper wing was next. With the damaged decal noted above I was in a bit of a dilemma. Two of the other paint schemes had lozenge decals applied to the tail assembly surfaces. Since the scheme I chose did not utilize the tail lozenge I just might have lucked out and had surplus decals that could be used to fill the damaged portions of the top wing. Matching the pattern would be the last challenge.

Do not rush the decal application. The lozenge pattern do require some care and effort to properly place and align. I used MicroSet and a light application of MicroSol for each decal. Allow plenty of time to allow each decal and solvent to dry before moving on. It may be tedious but the time and effort is well invested. The decals are probably the best I have ever worked with.

Rigging

The horizontal stabilizer rigging diagram is shown on the bottom of page 9, and the wing riging on page 10. This task with take some time and manual dexterity to accomplish, but should be worth the effort. I deffered the rigging portion of the build because of my concern for the fragile nature of the top wing and struts. Plus I was running out of time for the build and review submittal, and truly wished to avoid detention for a tardy submittal.

Final Assembly

Once the decals applied the wings were installed, and the propeller fixed in place.

Conclusion

This was my first World War I 1/48th scale biplane, and I enjoyed the challenge of the build and learned something about building World War I biplanes. The many tiny PE parts and rigging ( if tackled) would add to the effort, but would be worth it in the end. The application of the many tiny PE parts with raised detail gave me concern for the later placement of the full coverage lozenge decals and therefore I omitted the small parts from the build. The fitting of the top wing and landing gear required a bit of thought and planning at the end. My hat is off to the modelers who build World War I biplanes in any scale. Their skills and dedication are advanced beyond mine.

I wish to thank Eduard and IPMS USA for the opportunity to build and review this kit. I have wanted to build an Eduard Albatros for quite some time, and this was worth the wait. Thank you Eduard! Thank you IPMS USA.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews