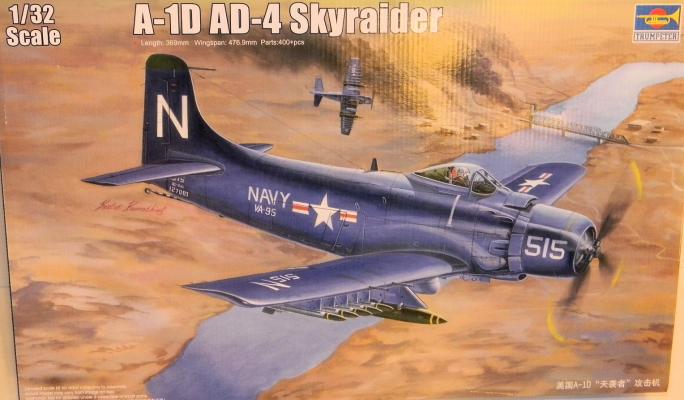

AD-4 Skyraider

As The Douglas Skyraider series was arguably the most effective and all-around aircraft of the Vietnam War, I won’t go into any history. If you don’t know about the Skyraider but are reading this, you should be aware of this versatile aircraft which was used by both the US Navy and US Air Force.

When I received the kit for this review, I first spent time going through the plans and the many sprues to get a feel of the fidelity to scale and detail level of the kit. I was excited by what I saw and anxious to get started with the build.

I must say that I do not suffer from AMS; I build plastic models as a hobby to relax and change my thought environment for a while. Although I have four specific reference books for the Skyraider series, none of them have 1/32 scale plans included, so I do not know if the length is 1.5 mm too short, nor do I care. The moldings look to follow the AD lines and the panel and rivet detail are very subdued and seem to follow the actual a/c lines.

What I did find during my review of the instructions, with the exception of the exterior colors, was inaccurate or in most cases missing color call outs. If you are interested in this kit, find yourself some references to utilize for color selection. An example of this is the recommended color for the exhaust pipes was black. No way!

That is the bad news, the good news is that there are 27 parts listed as unused, most of which are for the A-1H, including the novel “toilet bomb” used by VA -25 during the Vietnam War. Since additional AD models are not listed currently in the forward plans of Trumpeter, I would guess their availability depends on the sales success of this AD-4 model.

Now to the build. I will follow the plan build sequence rather than my usual haphazard approach. In sequence, as they were needed, all sprues were washed in Super Clean degreaser and thoroughly rinsed before being primed with all parts still on the sprues. By taking this time, I feel far more secure that my paint will stay where applied and not come off at the slightest touch.

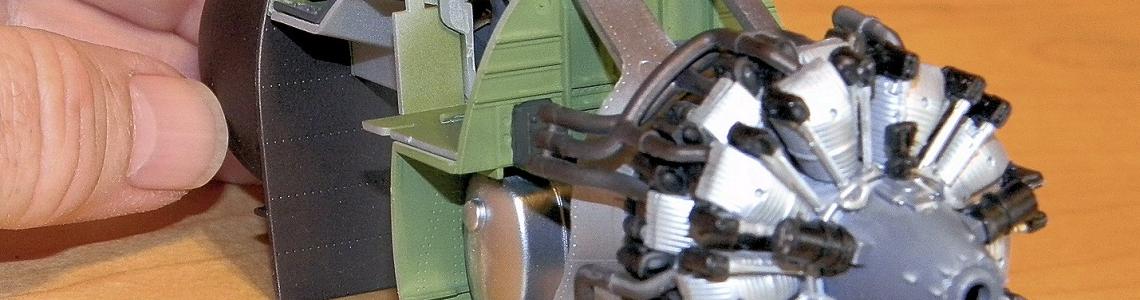

The Section 1 assembly plan covers the Wright R-3350 engine. To use the tired cliché, the engine is a model by itself. There are 77 parts in the engine build; a few more than in the usual 1/72 scale total kit!

For those without Trumpeter experience, you follow the plans, from top to bottom, left to right. Sounds simple, but doing this is important to getting the build correct and in the proper sequence.

For color, I used several shades of ALCLAD II LACQUER, including Exhaust Manifold to replace the incorrect call out of black.

You must do a special clean-up of the four engine cylinder castings as there are prominent pins inside the cylinders which might interfere with the gluing together of the cylinder parts.

The engine build is not too complicated, but there are two issues I wish to mention. The first is that the kit manufacturer has not made any provisions for installing the many ignition wires included with a double row engine. There are small dimples provided where the spark plugs would be, but that is it. If you want ignition wires, it is up to you. I didn’t want them, so don’t get out a magnifying glass to use on the photos. The second point is that after gluing the exhaust pipes together, I felt it was best to just install them dry, you will be surprised at the fit and then apply a tiny bit of glue afterward.

OK, on to #2 and #3 sections. The cockpit, engine firewall and main fuel tank are constructed in these sections. I encountered no assembly problems with these components. Again, color call outs should be disregarded, and references used. I decided to use a lightened black color in the cockpit for all surfaces above the bottom of the instrument panel and the seat. Below the instrument panel bottom I used interior green. I guess you could say that I am a contemporary of the Skyraider, as I was flying in the Navy at the same time as the early AD series. These are the colors I remember and were indicated by my references as well.

I used Testors 1183 Rubber to paint the fuel tank and the bulkhead attached to it. I also used Testors Model Master Acryl Green Zinc Chromate for all other interior color needs in these steps. With careful painting the cockpit looks quite good and considering that all the parts fit together very well, sort of negates the need for resin parts, if and when they might become available.

Sections 4, 5, and 6 were next. This involves building the tail wheel assembly and installing many interior former parts. I don’t believe any of the interior formers have a structural mission.

Before I go further, I want to mention my first suggested deviation to the plans. After installation of the tail wheel assembly, I accidentally hit the wheel several times requiring a little touch up with glue. Therefore, I suggest that you delay installing the tail wheel shaft (part H-26) until you are further along with the assembly.

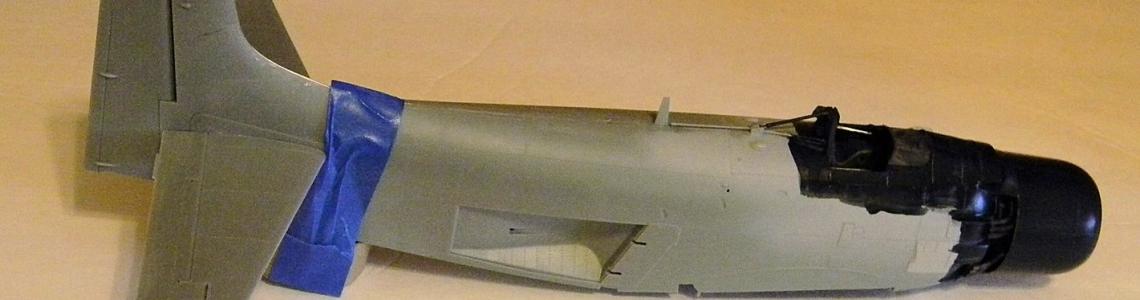

While I am writing about the tail wheel assembly, I should tell you about the first real assembly problem I encountered. After all interior parts were installed; I proceeded to close up the fuselage. All went well until I reached the rear of the a/c. Something had gone wrong with the placement of part G25 which would not allow the top rear fuselage near the tail to close up. I solved the problem with some heavy duty scraping with my hobby knife. My suggestion to you, since I don’t know the source of the problem, is to leave out G25 from the assembly. I don’t see it contributes any strength and is only there for theoretical show since when the fuselage is closed you can’t see it from any angle.

In step 6, you have a decision to make. Trumpeter provided two clear engine compartment panels (GP1 and GP7). This was an easy decision for me; I don’t use clear parts for looking at the insides of a model, so I primed them with the other parts and glued them in place.

In step 7, you have the option of having the engine cowling open or closed. Should I open up the engine compartment or close up the cowling? Well, my carpet monster, yes I have one of those, made the decision. Part K10, which would have served as the support for open cowling panels was swallowed up by my resident monster, never more to be seen. Therefore I “decided” to use the closed cowling and hope for the best next time. All the other parts in section 6 went together without issues. Be sure to drill the two small holes aft of the cockpit in order to be able to install the small air scoops indicated for that location. Disregard the bottom half of the instructions and follow the top half. No problems encountered here. I chose to paint the cowling interior green zinc chromate.

In section 8, there are a number of small detail parts relative to the cockpit to be installed. No issues here, but I did opt to set the windshield (GP2) aside for future attachment.

Section 9 deals with the rudder and tail horizontal flying surfaces. Since I did not plan ahead to have the elevators dropped out of neutral by positioning the control stick accordingly, I could not use the option given here by Trumpeter. As we go along you will see that the manufacturer offers several options regarding control surface positioning. All tail parts fit the fuselage well and no putty was needed.

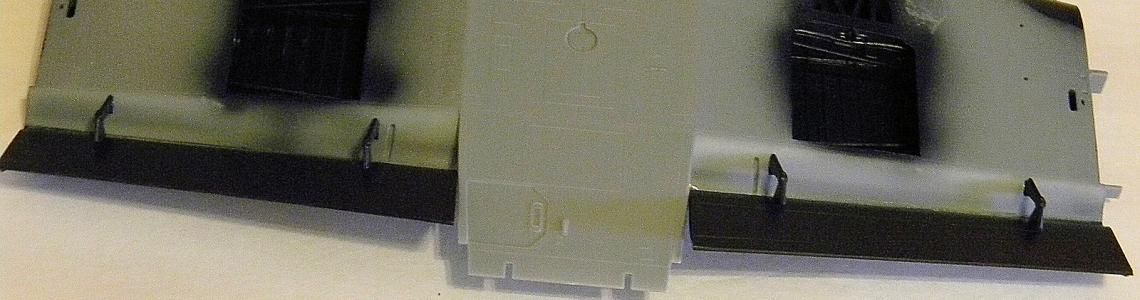

Section 10, starts the construction of the center wing section. There are many detail parts to dress up the wheel wells and joints. All parts fit together without issues. However, be sure that parts D11 and D13 are positioned with the cut out side facing down. Don’t ask how I know this! After the assembly was finished, I painted all parts visible from the closed bottom of the wing, Model Master Acryl Dark Sea Blue, the same color that will be used on the model exterior.

The actual AD series had Nylon material covers placed in the wing fold joints. These were not provided with the kit and I chose not to scratch build them at this time.

Sections 11, 12, and 13 deal with the construction of two of the 20mm wing cannons and their subsequent installation in the wing. The wing center section top parts are also installed here. Again, use your references to choose the type of gun barrel to use as you are given two types to consider. I chose parts J30. I also painted the wing near the cannon barrel protrusion after adding the top part to the bottom assembly to preclude having to mask the barrels later on.

Section 14 involves installing the wing flaps and the oil cooler flap outlet. Again, all parts fit together without effort or any touch-up. You may select to have the flaps up or down. I selected down and made the installation easily.

Sections 15, 16, and 17 deal with the construction of the landing gear and their subsequent installation into the wheel wells. Also the plans recommend the installation of the gear covers at this stage. Ordinarily, I would have waited to do this work until toward the end of the build but I stayed with the plans. I did encounter a small problem here. Parts H41, H42, H43, and H44, the gear door closing struts, are installed by very small holes in the panels forming the gear box. I would suggest placing these struts earlier at a consistent angle to have them in the correct place. You have two wheel facings to choose from. I used parts J38 which matched my references. Also, the only tire choice is rubber, but I must say they looked quite good on the wheels. Finally, I couldn’t resist adding brake lines copied from my references. Not a big deal but they did add some interest.

Section 18 deals with the side dive brakes. I finally broke the plan sequence and just constructed the brakes, along with the bottom dive brake as well. The inside of the brakes were painted insignia red and the outside the Sea Blue. I held off the installation until the finish. It seems the plans were written with the assumption that all parts, including the fuselage, were painted as built.

Section 19 Covers the construction of the bottom dive brake, tail hook, propeller, and two small steps. I painted the propeller hub white, and did not use the decal offered for the tail hook stripes. With small lines to guide me I just painted the lines black. Everyone has a trick to paint the tips of the propeller blades, in this case yellow. There were no build issues in this step.

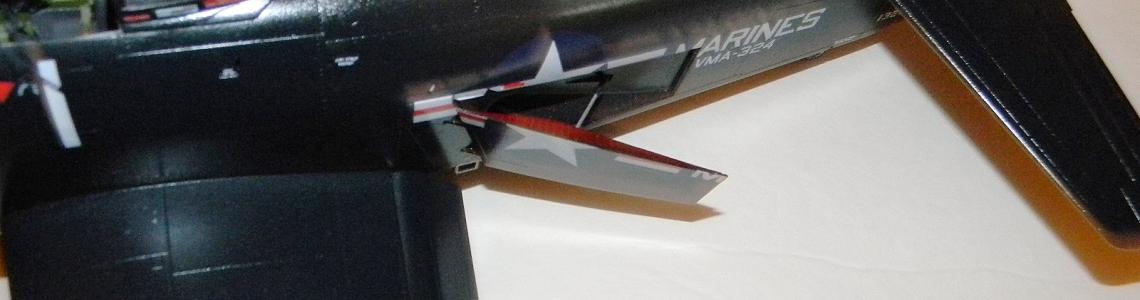

Sections 20and 21 cover the construction of the two outer wing halves. Section 20 deals with the left half and 21 the right half. The construction involves installation of the other two 20mm cannons, wing joints; either folded or unfolded, cannon detail covers, and the ailerons.

The ailerons proved to be problematic for me. The plans show that the ailerons should be installed with the side having three small raised triangles (presumably to locate static discharge wicks) on the top side. To me the airfoil shape of the ailerons’ indicated that the up side should be reversed, so that is what I did. The installation looks fine, but I am not totally sure that it is correct. Use your own judgment

Also, neat clear plastic parts serve as the wing navigation lights. They allow you to paint the part red or green depending on which side the light is located. I thought this was a clever to simulate the lights. Usually, you simply paint the bump molded on the wing tip, not very realistic. In this Section I decided to place one outer wing up and one down. While sometimes seen this way, it is not very realistic. However, I wanted to test the design for the wing fold as some kits are only designed to be up or down.

Section 22 shows the outer wings being attached in the folded position. As previously stated I decided to install one wing in folded position and the other in flying position. The folding attachment went very well. I should have done additional dry testing on the flying side as I ended up with a small gap at the wing joint and a sagging wing! I believe the normal wing joint will work correctly but the modeler should plan on cementing the total wing seam, from front to back and top to bottom to prevent the sag. Something to do better next time.

Section 23 illustrated both wings installed in the spread position.

Section 24 gives guidance on build the many weapons pylons which must be constructed. There are twelve rocket pylons for the two outer wing panels. There are three other larger pylons which can accommodate fuel tanks or large bombs. I chose the following “Korean” load out: The center line fuel tank, two AN-M66 2000 pound bombs and initially twelve 5” HVARs. However, when I checked out the HVARs for construction, I decided they were out of scale, way too small, more 1/48 scale. As a result the model has 12 empty rocket pylons, and two very large bombs as the weapon load out. I checked the rocket size out on the net and in doing so I discovered that Zoukei-Mura sells a weapon set for their A-1H which has both Korean and Vietnam weapons included. This set has the correct size HVARs and is reasonably priced.

From this point on I finished painting all components and completed the assembly of the model. In doing so I realized several things. One, the vertical fin mounted pitot tube, part #G-23, does not appear on the plans or the colored drawings. Find a reference to position it correctly.

Since this is a late release, there was no aftermarket masking available for the canopy parts. I gritted my teeth and cut small pieces of tape to do the job. The clear parts were well molded, very clear and fit well to the fuselage.

Second, the decals are far behind the model in quality. The large insignia decals have some kind of surface blemish which looks bad initially but does finally disappear after several coats of Future. In addition, most of the maintenance stencils are missing and some which are provided are not readable. With such high quality design, engineering and molding as is found in this kit, the time has come for Trumpeter to follow other Chinese kit makers and form an alliance with American decal manufacturers to have the quality of these items match the quality of the plastic parts.

It seems to me that Trumpeter’s A- Team had responsibility for the plastic part of this project.

I certainly hope that they decide to issue the Skyraider A-1H as a follow on kit.

Experience, common sense, and good references are needed to make this kit into a credible, top class model. Taking time to think out each step in comparison to the plans helps a lot.

I appreciated the opportunity to build this kit for review. 1/32 scale is my chosen size of model and I really enjoyed building the Trumpeter AD-4.

Thanks to IPMS/USA for the opportunity to build this kit and to Stevens International for providing it.

References used

- Walk Around A-1 Skyraider, Squadron/Signal publications. Number 27

- Douglas A-1 Skyraider , Warbird Tech, Volume 13

- Douglas Skyraider, Aero Publications

- Famous Warplanes of the World, Douglas Skyraider, No. 13, BURIN-Do Co., Ltd,

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.