X-15

The Aircraft

The X-15 was the first aircraft to “officially” make a space flight. The US considers any flight that reaches an altitude of 50 miles to be a space flight, and 8 pilots met this criterion. The FAI requires 100 km (62 miles) altitude for a space flight, and two flights, both with Joe Walker as pilot, achieved this height. The X-15 also holds the record for fastest manned aircraft, at 4092 mph.

With all the publicity surrounding the X-15 program, I was surprised that there were only three built, and you can build two of them, 56-6670 and 56-6671. The third, 56-6672 could be built from the parts supplied, but you’d need serial number decals.

The Kit

This is one of Dragon’s 1+1 kits, and it comes with enough parts and decals to build two complete X-15s. You also get the wheeled dolly that was put under the landing skids to allow the X-15 to be moved after landing.

When I opened the box, I was very impressed by the quality of the molding – crisp, clean, flash free, and a lot of tiny parts. I found it interesting that the Dragon designers made the fuselage halves front and rear instead of left and right. It sure made it a lot easier to hide the seam.

Building the Kit

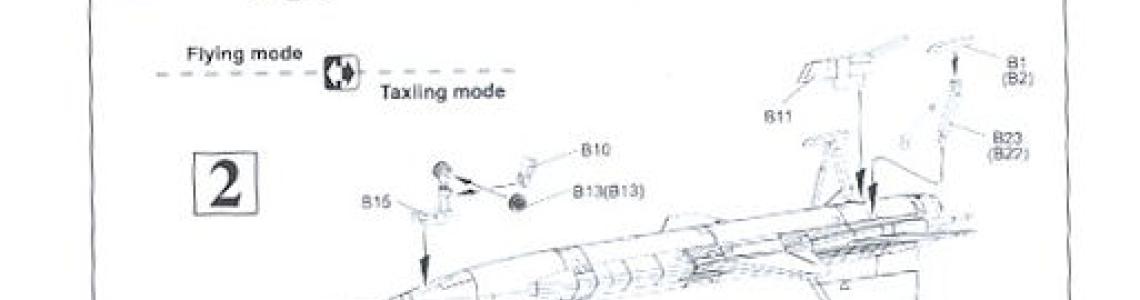

Looking at the 3-step instructions, this build is a piece of cake.

- Do the interior, insert it, put the fuselage halves together (front and rear), add the wings, stabilizers.

- Decide whether it’s going to be in-flight or on the ground. Half of the lower tail is jettisoned before landing, so the parts are different.

- Add the canopy, landing gear or doors, and finish.

Ah, if it were only that simple. Well, it really is, but there were some problems. The first one I encountered was that, after I put the nicely done instrument panel and seat into the cockpit and inserted it into the front fuselage half, it wouldn’t go in. The seat is too tall to fit past the bulkhead. Remove the seat, install the cockpit, reinstall the seat, and proceed from there.

Fit of the wings was spectacularly tight and good. There was a tiny gap, which I took care of with a bit of Mr. Surfacer. Splendid engineering.

I ran into another problem with the horizontal stabilizers. The part numbers on the instruction sheet appear to be switched between left and right, and I had to swap them to get the correct anhedral. So be sure to test fit these.

I was going to test-fit the nose probe when I discovered that the fuselage has a pin at the nose, and the probe also has a pin. I eventually solved this problem by putting part number B30 on the nose, which has holes front and rear. There’s no mention of this part in the assembly instructions, and parts B30 and B31 don’t appear in the sprue layout. Also, there are two different parts numbered 34 on the B sprue.

In addition, the callout for the nose gear wheels is incorrect, calling for part number B13 for these. These wheels are for the towing dolly, and are too large to fit. The nose wheels are part B16, and are smaller and very nicely molded.

Painting

Wow, the paint job was simplicity itself. One color, overall for everything but the interior, the wheels and the rocket motors. The color callout is for 36081 Dark Gray overall. I disagree with this, as the X-15s at NASM and the AF Museum are definitely black overall. I thought maybe Dragon might be correct, so I painted the aircraft 36081 first. Then I repainted it with Floquil Grimy Black after I saw that the color just didn’t look right. Coat with Future, and it’s ready for markings.

Decals

All right, Cartograf decals on a tiny little blue paper. Excellent decals, no problem, right? Well, wrong, there’s a problem. When I put the USAF on the wings, I discovered that the decal film didn’t really connect the letters. There was a tiny “bridge” from one letter to the next, but it was so fragile that any handling broke it. I got these in place, and then went to Plan B. I put Microscale liquid decal film over the US Air Force, the X-15, and serial number decals. This worked beautifully. I also appreciate that the decal reference numbers are printed in black on the decal sheet, so that you can read them.

Final Assembly

After putting the flat coat over the decals, I could now put on all those parts I would have knocked off while fooling with the decals. This part went very well, except for the one “tweezer ping” where I launched a part into another dimension. I fixed that, but all of these tiny parts fit beautifully, with all of the pins fitting cleanly into their holes.

Overall Evaluation

This is an excellent model. The parts fit is excellent, and everything just falls into place. It’s the closest thing to a “box shaker” kit I’ve built in a long time. The instructions aren’t anywhere near this good. But since this kit contains parts which are used on the “stretched” X-15, Dragon has the opportunity to fix this before they issue the next version.

Thanks to Dragon USA for the review kit, and to Steve and IPMS/USA for the chance to build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews