USN F/A-18E VFA-143 Pukin Dogs

While many other kits of the F/A-18E have been released in 1/72, Academy’s recent release is a continuation of its recent focus on enticing new people to the hobby. It is not a snap-tight kit with all the negative connotations that often has, nor is it a “normal” model kit. Like several of its other releases last year and this year, this kit is for the most part a push-fit kit, however, it showcases some of the best model engineering I have seen as many joints where the parts fit together are exquisite and most of them vanish once assembled.

The kit is comprised of 6 sprues of grey plastic, a clear canopy and individual moldings of the front fuselage, the lower aft fuselage, the nose and an ejection seat. The kit includes two different styles of vertical tails. The ones on the A sprue are not used, so I clipped them off and put them into the parts box right away to avoid confusion. The instructions are actually split into 3 parts, Manual 1 deals with assembly of the airframe itself, Manual 2 is for the ordinance and finally there is a large double sided color sheet for decaling and illustrating the two decal options. Both options are for the “CAG” bird of VFA-143 Pukin Dogs. One is toned down dark grey markings, but the other has bright blue vertical stabilizers and some of the standard markings are done in white and blue instead of grey.

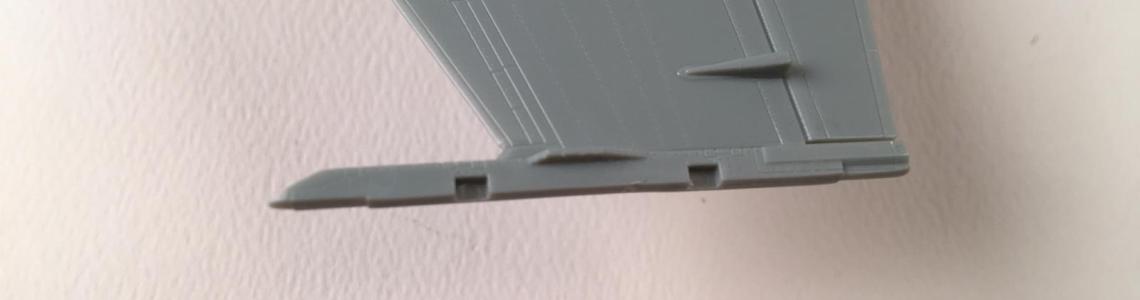

Construction starts by inserting the lower wing/leading edge extension panels into the upper wing/fuselage part. Academy has modeled almost the entire upper fuselage from the just in front of the engines to just short of the radome as a single piece. The piece also includes the upper wings and the lower wings outboard of the wing folds as well as the slats and part of the main flaps. Into this you snap two lower wing/leading edge extension panels. The joints on the wings are very well designed and follow actual panel lines. The fit is outstanding and if care is taken the joints pretty much disappear on the wings. The joints on the leading edge extensions fit very well with just a slight gap. As the gap is pretty much the same width as the other panel lines, I did not fill them. In looking at photos later, I probably should have as they are not as prominent on the actual aircraft as I thought.

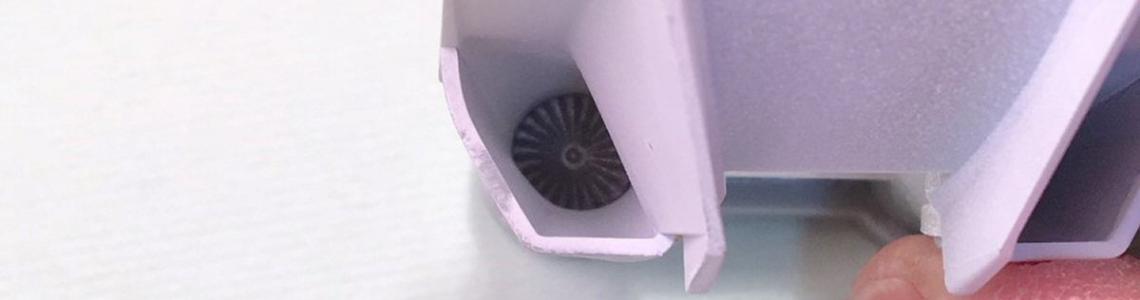

The next step is to snap the main gear bay into the lower fuselage. The gear bay has some nicely molded details, but I am sure Eduard will soon have an etch set out to add more. This step also deals with the assembly of the engine intake trunking. This is comprised of an upper and lower half that snap together. The joints are very well thought out and follows some natural corners in the intakes so the seams are not noticeable once constructed. Surprisingly, there is nothing telling you that the intake trunks should be painted white on the inside, but a quick check on the internet shows that they are, so I painted them at this stage while they were accessible. The kit does include decals representing grills or vent holes in the intakes, but I found the instructions on which ones go where confusing. I also discovered that the numbers listed in the instructions do not match the numbers on the decal sheet. Fortunately, the shapes are very distinctive, so it was easy to locate the correct ones. As I expected to do some sanding and filling eventually, I left the decals out of the intakes until later. After you snap on the engine compressor faces piece, the whole intake assembly snaps very solidly into the lower fuselage. The fit is good, but not perfect, so I did a little filling and sanding to blend the intakes into the lower fuselage. In hindsight, I should have thinned down the leading edges of the intake lips as they are fairly thick and blunt, unlike the real Super Bug’s. Step 2 would also have you install the main landing gear before joining the upper and lower fuselage halves, but as I tend to be ham-fisted sometimes, I left the gear off until after painting.

In the next step the lower fuselage and the upper fuselage/wings assembly are joined together, trapping the horizontal tails in between. The horizontal tails are a single piece, but the part connecting them is a thin plastic bar, not a rod, so they can only be posed in the neutral position out of the box. Fit was very good and the joints were very well thought out as most of them are not visible after assembly. I ended up having to do a little sanding and filling on the aft fuselage in front of the horizontal stabilizers as there were some slight gaps.

With the bulk of the airframe assembled, it was time to assemble the cockpit. The kits is clearly designed for all three variants of the Super Hornet, in fact the sprues are labeled F/A-18 E, F, G, so I expect to see a Growler in the not too distant future. As the E is a single seat bird, the instructions illustrate the assembly of just the front office. There are decals for the side consoles, but I found them to be a bit short, so I supplemented them from some left over decals from another build. There is nicely engraved detail on both the instrument panel and the side consoles. Since the decal sheet only provides decals for the green faces of the multifunction displays, after painting the panel flat black, I dry brushed it with white and light grey to get the details to pop. I elected not to use the decals for the panels as the decals depict green panels, but when there is no power on the aircraft the displays are more black than green. I painted Tamiya clear green over the black base paint to get the effect I wanted. As the kit includes both the front seat instrument panel and the rear seat instrument panel, pay attention to the part numbers when building the panels, or even better snip off the rear panel parts and put them in the parts box before starting. I found out the hard way that the rear instrument panel will fit under the front instrument coaming if you push hard enough, but then the lower nose piece will not connect to the upper fuselage part.

The seat is nicely molded in two parts somewhat simplifying painting and construction, however no seat harnesses are included either molded on or as decals – another opportunity for aftermarket etch! I left the seat out until I was ready to put on the canopy to avoid it falling out during the rest of the build. After the cockpit tub is painted and decaled, it is glued into the lower fuselage part and this is attached to the completed wings/intake sections. In test fitting I noted that the fit below the cockpit and to the radome piece was not as crisp as other joints, so I decided to glue the lower fuselage half on at the same time as I glued on the radome. As there is a lot of airframe aft of the main gear, there is real risk of a tail sitter, so I first loaded up bunch of fishing weights and other metal objects in the nose cone part, covered them with superglue and let the whole thing set for a couple of days.

When the superglue had set I joined the lower fuselage, nosecone and main airframe assembly all at once. This allowed me to hold things together while the glue set and as a result some of the seams I was concerned about on the nose to fuselage join went away. I still had some small gaps on the fuselage sides under the cockpit, but these were easily fixed with filling and sanding. The nose cone attachment is well designed and molded, especially near the nose gear bay and allows some really fine details to be molded in. Again most of the seams are located in places where there is supposed to be a seam such as where the fuselage joins the leading edge extension, so there was nothing to fill there. There is one bad seam between the intakes where the front fuselage meets the aft fuselage and results in a little step between these two sections. However, I discovered that since the centerline fuel tank pylon is so short in height, once you attach the centerline fuel tank, this seam is invisible under the tank. I therefore did not mess with it.

Next you also attach the upper fuselage panel covering up the rear cockpit. The fit here was OK, but I ended up doing a little filling and sanding to blend it in. At this point you are instructed to attach the vertical tails; however, as I had decided to model the jet with the bright blue tails, I left the tails off for now to make painting them easier. The rest of Manual 1 is the installation of the landing gear and landing gear doors. I always paint the landing gear and doors off the model and install them later on, so I moved on to Manual 2 and the assembly of the ordinance.

One of my disappointments with the kit is that it provides very little ordinance. There are two sets of sprue C, so you get two wing tanks with pylons, two centerline tanks with pylons, two AIM-9X Sidewinders, two AMRAAMs and two 500 pound GBU-38 JDAMs. There is also a guidance pod on one of the other sprues that mounts in the left missile well on the fuselage. I know JDAMs are pretty advanced weapons, but it seems pretty inefficient to send in a Super Horner with just two 500 lb. bombs, so I would have liked to see more ordinance options. As with the other joints on the kit, the tanks and weapons all attach without glue, which results in my second complaint about the kit. As the AIM-9s mount on the wingtip rails, in order to get a nice solid joint, the Sidewinders have large rectangular pegs on one side that are supposed to snap into recessed holes on the underside of the wingtip launch rails. I test fit the missiles and hated the way they looked, so I took out my razor saw, sawed off the pegs from the missiles, glued them into the slots and then filled and sanded everything smooth. Another gripe is that for a reason that escapes me, Academy molded the AMRAAMs in three parts instead of just one, so you have to cut out, clean up and carefully glue the three sections together. These joints are not tight press fits, so glue will be needed here for anyone wanting to use the AMRAAMs.

The final parts to go on are the under nose probes, the upper and lower antennas, the heads-up glass and the canopy. Regrettably the canopy is a single piece and can only be displayed closed. Now that everything is together, it is time to paint. As I wanted to model the colorful CAG bird, the first thing I had to do was find a paint to match the blue on the tails. After looking at several photos online and visiting my local hobby emporium, I chose Testors 1110 Bright Blue enamel paint. As photos show the entire tail painted this color, fortunately Academy’s parts breakdown exactly matched this split. While the tails were drying, the rest of the model was also painted using Testor’s enamels, FS 36375 Light Ghost Grey underside and FS 36320 Dark Ghost Grey on top. The engine nozzles were painted Testors Steel and Tamiya Aluminum. Once the paint had dried, I put on several coats of Future to prep the surface for decaling.

This is the second new Academy kit I have built recently and in both cases the kit decals were outstanding. They reacted perfectly to Micro Set and Micro Sol, settling right down over the delicate details, include the screens in front of the nose gear bay, under the leading edge extensions and near the engines. However, be prepared to spend some time decaling, as there are a lot of stencils all over the airframe. The color painting and decaling guide does a great job showing where they all go. I used a pencil to check off each decal as it was applied to help me keep track. Even then it took me 2 evenings to get everything on. My only complaints with the decals are that the decal of the stripes on the tailhook would not lay down and conform to the hook shaft (so I painted the stripes) and that the sheet has absolutely no decals for any of the ordinance pylons. If you have ever looked at a US Navy pylon, they are festooned with stencils. I used a couple of unused decals from the sheet on some of the pylons to punch them up.

After the decaling was complete, I added the landing gear and the doors. The gear fits very solidly and snuggly, but I added a bit of glue for insurance. Don’t forget to paint the gear door on the nose gear retraction strut light grey instead of white – it is noticeable. The gear doors have small rectangular pegs that are supposed to fit into square recesses in the gear wells and many of them do. For those that did not, I gently sanded the pegs and repeatedly test fit them until they slid into place. For those obsessed with accuracy, you will need to remove the square attachment recesses, however the ones in the nose gear wheel are as tall as the gear wheel - so good luck. I then airbrushed another coat of Future to seal things in and then put down a coat of clear flat, everywhere except the tails as the tails on the real aircraft are glossy and flashy. Once the final coat dried I removed the canopy masking, polished it with a glasses cleaning cloth and press mounted the ordinance, except for the Sidewinders – which were superglued on.

While I have a few minor gripes with the kit, I really enjoyed building it and look forward to building a Growler when it comes out so that I can compare it to the Hasegawa Growler that is approaching the painting stage. As I said above while this kit is geared towards the entry modeler, it is not a snap-tight kit, the moldings are outstanding, the decals are real decals not stickers and the kit will give a more experienced modeler an opportunity to have a fun build and then really go to town weathering the model.

Most highly recommended. Thank you to MRC/Academy for the review sample and to IPMS-USA for letting me build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews