USAF KC-135E

The Aircraft

The KC-135 was the US Air Force’s first jet refueling aircraft, replacing the KC-97. The 135 was developed from the same prototype as the 707, but has much more in common with the Model 720. The 135 entered service with the USAF in 1957. The last KC-135 was delivered in 1965.

The KC-135E was an interim between the KC-135A and R. The E model came about when it became apparent that the A model just didn’t have the power and range needed to support the global mission of the US Air Force. The fix is the same one used on the Boeing 707 and 720, updating the engines from P&W J-57s to TF-33s. The re-engining continued with the KC-135R, which has GE/SNECMA CFM-56 engines. The Air National Guard and Air Force Reserve flew the E model.

The Kit

This is a new tool version of the “Military 707” family. Minicraft has released an E-3 AWACS, E-8 JSTARS, VC-137 and C-137/C-18, but these aircraft were all modified Boeing 707s. The 135 is different enough that they made a new mold.

There have been criticisms of the nose shape of the previous 707 based kits, and I have used the 2 Mikes Resin replacement noses to correct the issue. Well, somebody at Minicraft deserves an extra coffee break, because the new kit has the correct nose shape. YAY!!! Of course there are some problems with fit and assembly, but nothing that is a show-stopper. The other big problem I’ve had with the previous kits was that the instructions failed to tell you to install the partition between the main gear wells before gluing the fuselage halves together.

This also has been corrected on this new kit; the gear well partition can be installed any time after the fuselage halves are assembled.

Building the Kit

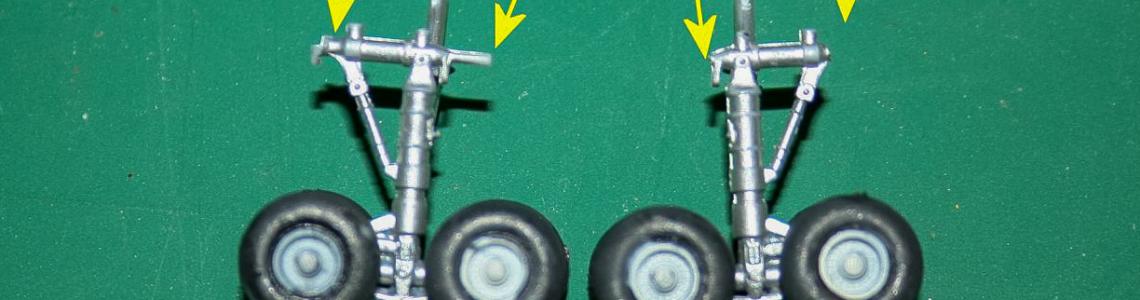

I pretty much followed the instructions through the assembly of the fuselage, wings and horizontal stabilizers. The nose-gear bay and nose gear have to be installed before the fuselage is glued together. I painted the plane overall gray, although the color I used is the color form the early 80s. Painting was simple as the aircraft is one color overall, with the wheel wells in white and the anti-glare panel in black. I assembled and painted the engines, but didn’t install them until after decaling was completed. The same was true of the landing gear, although I did test fit the gear at this point. The first try was disappointing as there are extensions on the base of the gear at the front and rear which wouldn’t allow the gear to be installed. Trimming these extensions allowed the gear to fit properly. Also, don’t make the mistake I did and install the main gear inner doors before the gear legs are in place. You can’t see where the inner shaft goes into the well if those doors are there.

There’s another good thing, the cockpit fits beautifully; much better than a lot of them I’ve done.

Decals

The decals are from Cartograf, and provide two options from 2004: a Kansas ANG aircraft from the 190th ARW, or a New Jersey ANG’s 108th ARW with a large tiger painted on the fuselage sides for the Tiger Meet. Of course I decided to build one I was more familiar with, and made a new tail band, serial number and wing insignia for the 126th ARW when they were at Chicago O’Hare Airport, before they moved to Scott AFB in southern Illinois.

I had zero problems with the kit decals. I wish had all that good luck with mine. As it is, I had to reprint the serials twice.

Finishing Touches

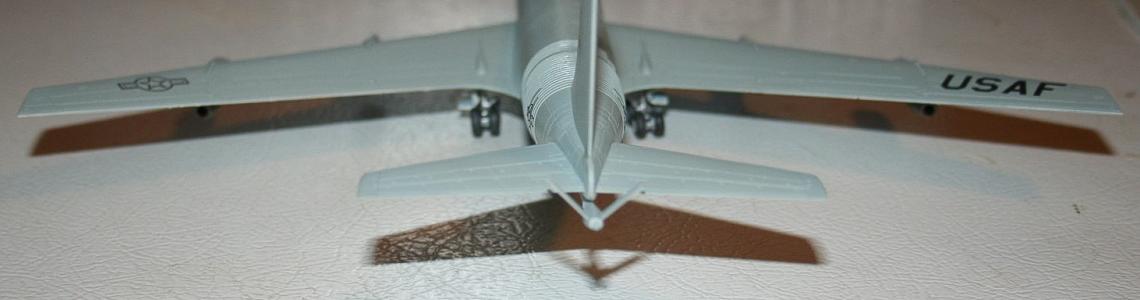

After the decals were applied, overcoated with a gloss coat of Future, and then finished with Testors acrylic flat, it was time to put on all of those parts I’d have destroyed while handling the model for decals.

I attacked the main landing gear first. The outer gear doors are molded flat as they would be on an aircraft “in flight”, so they need to be folded to represent the plane on the ground. I managed to crack or break both of them, but a bit of gel type CA fixed this. After the main gear was installed, I reinstalled the main gear inner doors. The fit on these was problematical, requiring a good bit of fussing and filing to get them in. Additionally, although the center divider is now installable at a later stage of construction, there are no locating pins or slots, and I managed to get it not quite right, thus making installation of the main gear inner doors even harder. The single door on the nose gear was finicky as well, but again CA is my friend.

Installing the engines on the wing was great. The fit is so tight that I had to carefully remove a bit of the sprue attachment I had left on a couple of the pylons. Also, the inner engines have one pin & hole while the outer engines have two. You can’t get it wrong!!! Another YAY!!!

After the engines, I installed the refueling boom and the top piece on the tail. The tail piece is pretty fragile, so watch it. I broke mine while removing the sprue attachment remnants. CA is my friend again.

Overall Evaluation

Highly Recommended. There are a couple of places where there could be some help for parts installation, like making extra main gear doors pre-folded, and a locating method for the main gear center partition, but the fix for the nose is outstanding. I had no fit issues for the fuselage, wings or stabilizers. The engines went together nicely. I can’t wait for the A and R models to be released.

Many thanks to Sharon Blackwell and Minicraft Models for supplying this wonderful kit, and to IPMS/USA for the opportunity to build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews