USAF F-15E 333rd Fighter Squadron

Over the years there have been quite a few F-15E Strike Eagle kits released by several different kit manufacturers in 1/72 scale. However most of these kits were adaptations of the manufacturer’s F-15B or D kits with some extra parts to address some of the differences between the B/D and the E airframes. Academy’s recent release is a not an adaptation of another two-seat F-15 kit, but instead was designed from the outset to be a Strike Eagle.

The kit is also a continuation of Academy’s recent focus on enticing new people to the hobby, but it is not a snap-tight kit with all the negative connotations that often has, nor is it a “normal” model kit. Like several of Academy’s other releases, this kit is for the most part a push-fit kit, however, it showcases some of the best model engineering I have seen as many joints where the parts fit together are either on actual panel lines or are in locations that are easily filled. The fit is spot on so most of the seams vanish once assembled.

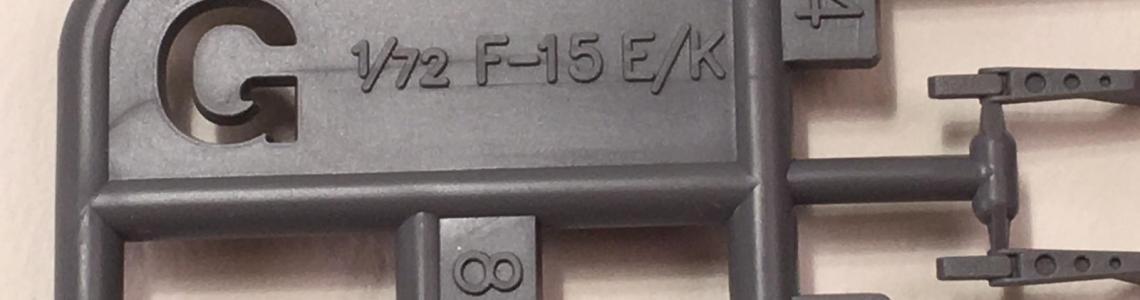

The kit is comprised of 8 sprues of Gunship Grey plastic, individual moldings of the lower main fuselage and two ejection seats, and a clear sprue with the canopy, the HUD glass and the glass for the Sniper pod. Several sprues are labeled F-15E/K so a Korean Air Force Slam Eagle is clearly coming down the road. Sprue F also includes unused parts for GE F110 engines, so Academy is presumably planning on issuing a kit for Saudi or Singapore Air Force Strike Eagles. I clipped all of these parts off at the start and put them in the spares box to avoid later confusion.

The instructions are actually split into 2 parts, Manual 1 deals with assembly of the main airframe itself, Manual 2 is for the drop tanks and ordinance and includes the decaling instructions. The first page of Manual 1 lists the paint callouts with references to Humbrol, GSI Creos, Lifecolor, Testors/Modelmaster, Revell and Vallejo paints along with the appropriate FS numbers for each color.

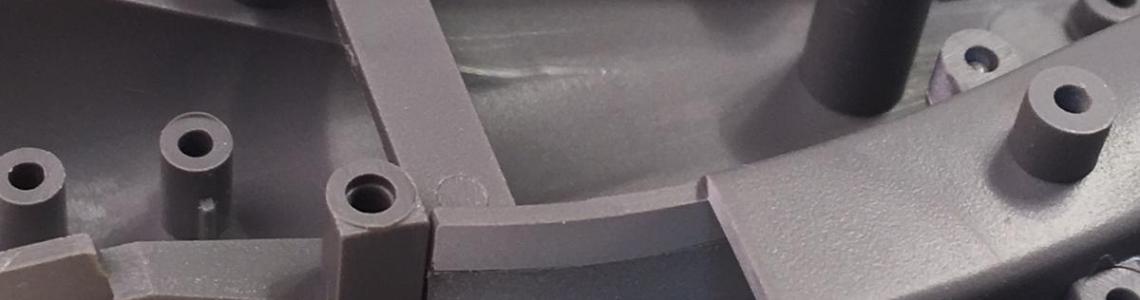

Construction starts with the assembly of the intake trunks. A nice feature is that the kit provides full length intake trunks. They are molded in upper and lower halves that snap together tightly, however, the seams inside the trunks are pretty noticeable. Surprisingly the instructions do not make any mention about painting the intake trunks. While the forward portion of the Strike Eagle’s intake trunks is Gunship Grey, the aft section is actually white. I decided that I will eventually cover the intakes with FOD covers, so I did not spend any time trying to fill the intake seams, but if you don’t want to do this, you will need to spend some time on these seams. The fronts of the engine fans are then attached and the whole assembly snaps into the lower fuselage section. Next up is the assembly of the aft portion of the engines and the lower aft fuselage. This area is designed so that you can paint the natural metal sections under and around the engine bays separately before attaching them to the Gunship Grey fuselage. I elected to paint the interior parts of the exhaust area before assembly, but not the exterior sections as I was not sure just how tight the fit would be. Once assembled, the engine exhausts are installed in the lower fuselage. The section of the upper fuselage that is natural metal is then attached to the lower engine section, trapping the horizontal stabilizers in between.

The cockpit assembly is next and the parts are very nicely molded with good raised details that really pop-out with careful painting. Academy does not include any decals for the side consoles or the instrument panel other than green squares or rectangles for the display screens. As you can see a lot through the canopy, take your time painting this area. I painted and decaled the ejection seats at this time, but I did not install them until the very end of the build in order to avoid knocking them out at a later stage. The assembly sequence provided in the instructions has you installing the nose gear, tire and nose gear doors even before you install the nose gear bay into the front fuselage halves. I decided that I knew better, so I left off the nose gear strut and snapped in place the forward nose gear door which is closed on the ground. I later discovered this was not the optimal way to do this as I could not get the nose gear strut installed around the closed nose gear door. In the end I ended up cutting off the retraction strut where it attaches to the nose gear strut and then re-attaching it after painting once the strut was in place. I also discovered later on that the small nose gear door that stays open is actually designed to be attached to the nose gear before the gear is installed as it slots over a raised attachment point on the back of the strut. Once the strut is installed, it is impossible to squeeze the attachment section between the nose strut and the back of the gear bay, so I ended up slicing off the bottom of the attachment area so that I had a slot instead of a rectangular hole, then I was able to slide the door into place.

Before you close up the two nose sections, trapping the cockpit and nose gear bay in between, you need to install the lower antennas. The kit provides 2 configurations with slightly different shape antennas, so check your references as to which are appropriate for the jet you are building. Unfortunately the instructions do not tell you which antenna configuration is appropriate for any of the aircraft on the decals. The radome in installed next and the fit is fantastic. Initially I did not glue the radome on as I wanted to be sure I had some place to install nose weight if I needed to prevent the model from being a tail sitter, but no weight is needed. The fit was so good that I still have not glued it on!

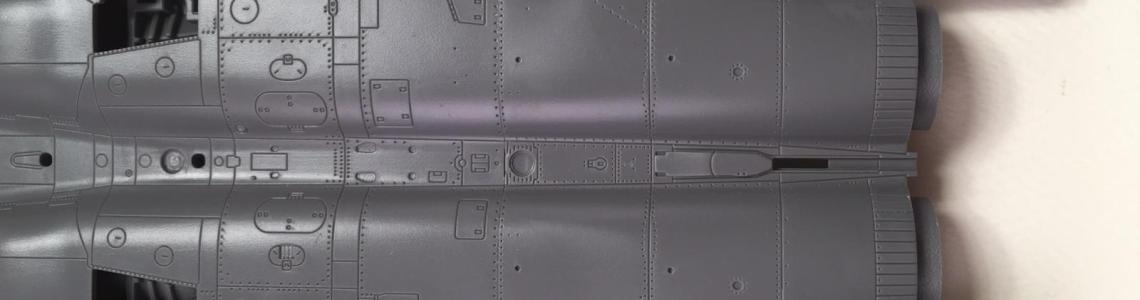

Academy has molded the entire upper fuselage from just aft of the cockpit to just in front of the engines as a single piece. The piece also includes the upper wings and the lower wings outboard of about mid-wing and therefore eliminates the problem encountered with many other F-15 kits where the wings are separate and have to be attached then faired into the fuselage. There are inserts for the inside sections of the lower wings, but the seams are mostly on existing panel lines and either fit really well or the joint is easily addressed with Mr. Surfacer. This step also includes the assembly and installation of the intake ramps. The ramps can only be installed in the fully raised position, which is the normal static position. The completed nose section is then snapped into place into the upper wing piece and the fit on the fuselage spine between these two parts is excellent.

Next, the upper and lower fuselage assemblies are brought together and the only area I had to do any filling was where the lower fuselage section meets the nose section, but again this was addressed with Mr. Surfacer, although use it sparingly towards the top of the joint as it is not easy getting in between the intakes and the fuselage sides to clean up the joint. The Strike Eagle’s signature conformal fuel tanks/fast packs are molded as part of the lower fuselage piece with the exception of the curved front sections, which are attached next. One side fit great, while the other required just a little filler to address a slight gap. In step 8, I installed the rear fuselage extensions, but not the exhaust nozzles as these are much easier to paint separate from the main airframe. The vertical tails correctly depict the different tops of the F-15E and are installed in step 9. I recommend leaving part H10 off until final assembly as it is a vent or grill that is entirely natural metal instead of Gunship Grey. The final stages of Manual 1 are the installation of the main landing gear and doors. I left all of these off until final assembly.

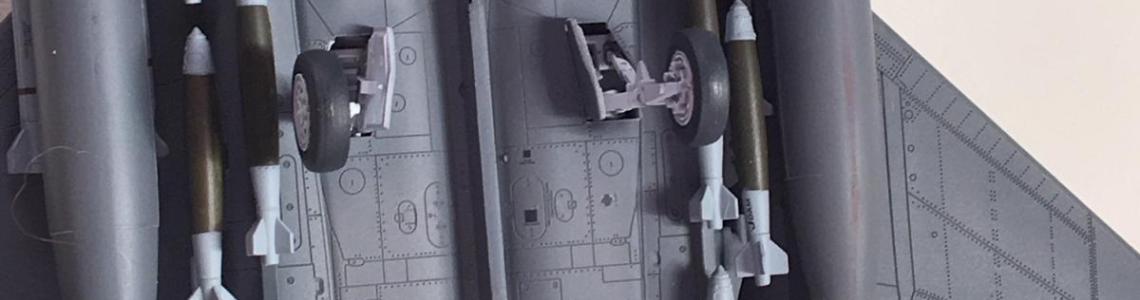

Manual 2 deals with the installation of the weapons racks and the weapons. The bomb pylons for the CFTs simply snap into place, but I reinforced the joins with Tamiya extra thin cement for security. The kit provides two options for the forward most pylon on each side, but no indication as to which to use. Whichever you select, make sure you use the corresponding pylon for the other side so that they are symmetrical. The kit also includes a centerline pylon, but surprisingly nothing to put on it. For a weapons load, the kit provides 14 GBU-38 JDAMs (12 of which are used), 2 wing tanks, 2 AIM-9X Sidewinders and 2 AIM-120 AMRAAMs. It also includes the AN/AAQ-13 and AN/AAQ-14 LANTIRN pods and the AN/AAQ-33 Sniper pod, so you will need to check your references to see if the jet you are modeling carried the AAQ-14 targeting pod or the Sniper pod. The GBU’s are molded in two parts, but the attachment points are square instead of round to ensure that the bombs are assembled with the tail fins in an “x” shape. A nice change from the Academy F/A-18E kit I built recently is that the AMRAAMs in this kit are molded as a single part instead of three. The only construction issue I had with the weapons was there was a pretty visible seam on the drop tanks that took some time and filler to eliminate. Academy also used a very different attachment method for the AIM-9s in comparison to the F/A-18E as on this kit the missiles have a small tab molded on the side of the missile that slides nicely into the missile pylon instead of the two large tabs used on the Super Hornet. All of the bombs and missiles suffered from ejector pin marks; however most of these are located near the attachment points for the weapons, so they were covered by the pylons. The marks on the AIM-9s were located closer to the missile seeker head, so a little filler was required to eliminate these marks. Step 15 directs you to install the pitot tubes on each side of the front fuselage and this is fine if you are modeling two of the three options provided in the kit, however, if you are building the jet from the 336th FS, leave parts H8 and H9 off until after decaling as H8 interferes with the application of the large dragon decal. The final assembly step is for the installation of the speed brake. The kit allows you to display it either fully extended or retracted. As it is usually retracted, I installed it closed. Mine did not fit flush all the way around so I ended up having the use some large clamps to hold it in place while the glue set. If you are going to close the speed brake, I recommend you install it back in step 4 before you attach the lower fuselage so that you can easily get clamps onto it.

As the Strike Eagle is overall Gunship Grey, painting is pretty straight forward, however, the color of the plastic is pretty close to Gunship Grey, so at times it was hard to see what had been painted and what had not. I used Dark Aluminum for the natural metal areas of the fuselage with steel and burnt iron for the exhaust nozzles. The weapons were painted according to the instructions, but in hindsight, I should have painted the missile fins black or dark grey instead of Light Ghost Grey like the missile bodies.

Several coats of clear prepared the model for decaling. The decals are printed by Cartograf, and provide 3 options, one aircraft from each of the 333rd FS, the 335th FS and the 336th FS. This is the third new Academy kit I have built in the past year and in all three cases the kit decals were outstanding. They reacted perfectly to Micro Set and Micro Sol, settling right down over the engraved details, include the fasteners on the nose access panels and the stripes on the missiles. The only decals that I had problems with were the squadron bands on the vertical tails as they did not want to conform to the lumps and bumps on the kit. I did get them to nestle down pretty well with some trimming, but I then had to use some insignia yellow to paint the leading and trailing edges of the tails to match. A word of warning; be prepared to spend some time decaling, as there are a lot of stencils all over the airframe and on the weapons and pylons.. The decaling guide does a great job showing where almost all of the stencils go, with a few hiccups that I forgot to record. Don’t be surprised if you have some leftover decals, I did and I think some of them apply to other variants to come. I used a pencil to check off each decal as it was installed. Unfortunately the decaling guide for the markings specific to the three options is way too small and a little hard to read. There is also a mistake as the Wing badge is correctly depicted as being on the right side of the CFT, but it is incorrectly labeled in the instructions as decal #3 when it should be #2. Of you are building the 366th FS aircraft, find some photos of it online to assist you in getting the dragon properly situated. Mine is a little low as I had already glued in part H8 before painting and could not get the decal around it.

Once the decals had all settled, I washed the model lightly to remove leftover decal solvent, then applied a coat of gloss to even things out, followed by a coat of flat. When the flat had dried, I first installed the landing gear and the landing gear doors, then I removed the canopy masking, popped the canopy off and installed the ejection seats and the HUD glass, then reattached the canopy with white glue. The canopy can only be installed in the closed position and I ended up shortening the attachment pegs slightly to get the canopy to sit squarely. I then flipped the model over and started installing the weapons and sensors. I used the two LANTIRN pods as I plan to install the Sniper pod on an F-16 in my stash. Both pods snapped nicely into place. I had read another review of the kit that recommended shortening the attachment pegs for the GBUs to get them to sit better on the pylons, so I snipped a little off each attachment peg and was pleasantly surprised how well they all fit. The missiles snapped nicely onto their respective pylons and the fit of the tanks to the wings was excellent as well.

While I have a few minor gripes with the kit, I really enjoyed building it and it really looks like a Strike Eagle. Some of the parts such as the landing gear scissors and the exhaust nozzles are very simplified versions of the real thing, but I feel they do not detract from the model very much, and I am sure that the aftermarket companies will address these shortfalls. As I said above while this kit is geared towards the entry modeler, it is not a snap-tight kit, the moldings are outstanding, the decals are real decals not stickers and the kit will give a more experienced modeler an opportunity to have a fun build and you could really go to town weathering the model, or arming it with aftermarket weapons.

Most highly recommended. Thank you to MRC/Academy for the review sample and to IPMS/USA for letting me build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews