U.S. Motor Grader - Part 2

This is a great kit, and will build a beautiful model of a unique WWII vehicle. Building this model is a challenge however, and will require lots of resin experience and careful fitting of many delicate parts.

Originally introduced as the "Caterpillar Diesel No. 12 Auto Patrol" in 1938, the grader was renamed as a ‘Motor Grader’ one year later. The U.S. Army used the Cat 12 Grader during WWII in all theaters for airfield and road work. This is an iconic vehicle that has long deserved a quality kit and Plus Model has delivered a beauty. The Grader follows Plus Models other excellent full resin dozer kits.

An Out-of-the Box review is located here U.S. Motor Grader - Part 1.

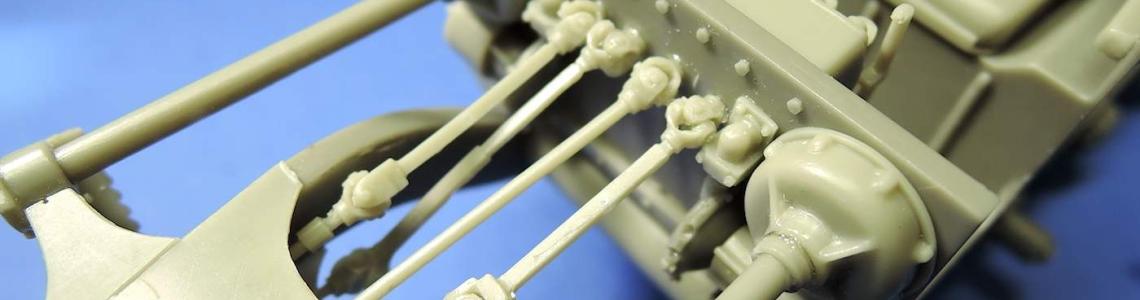

There are 236 parts cast in a medium gray resin with nice detail. Some of the parts, like the control levers, are extremely finely molded and close to true scale. The parts have some mold seams and occasional bubbles typical of most resin kids. None of them posed any real problem. All of the parts are attached to casting blocks and many have flash that needs to be cleaned up. Quite a few of the parts had broken free of the casting blocks requiring some searching for the right part. The kit also includes photoetch, a small decal sheet, and wire.

A photo DVD is also supplied with the kit. The DVD is organized into the model sections and has photos of almost every assembly step. The DVD is invaluable for locating parts and being able to see the correct assembly procedures. Thanks to Plus Model for including this valuable tool with the kit! It would be nice for other manufacturers to do the same thing.

Photos of a restored U.S. grader in U.S. Army Earth Movers by Wings & Wheels Publications are also great references for assembly of this kit.

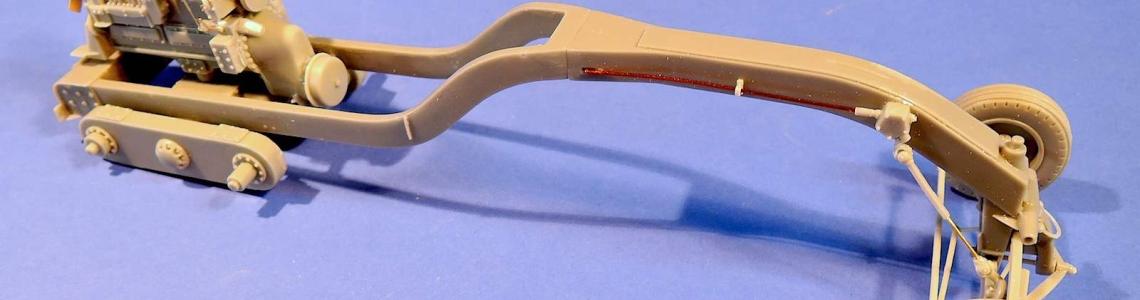

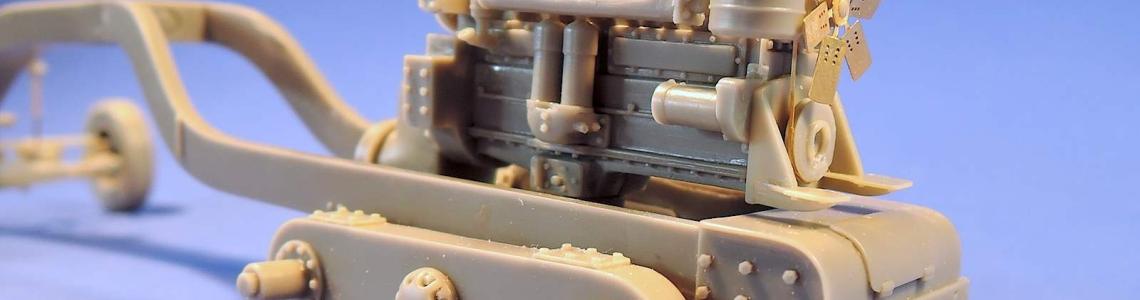

The first step assembles the frame and transmission. The two sections of the frame have a simple pin connection, which allows the potential for rotating the two sections of the chassis out of alignment. I aligned mine by eyeballing the front axle, and it ended up being slightly out of parallel with the rear of the chassis. It would be a good idea to fasten the two chassis sections together using a jig that aligns the front axle with the rear chassis section to get them in correct alignment. This step is indicative of the kits assembly, which can end up with an accurate kit but requires a lot of care aligning and fitting parts. The cross member in the rear chassis section had broken off in the bag and had to be glued back together. This is a critical piece for installing the engine and it broke off several times during assembly.

Installation of the engine is next, requiring eyeballing the alignment of the engine with the chassis to get it straight.

Page 3 installs the rear wheels. I decided to hold off installation of the wheels until later on when they're painted and I can align them with the front wheels so all six wheels touch the ground. The instructions show two part #10 wheels and two part #11 rear wheels. The parts supplied with the kit are numbered #8, 9, 10, and 11. The correct location for each of the wheels can be determined by the recess on the back of the wheel, and the direction of the tread pattern. All four wheels should have the tread pattern pointing forward on the top.

Pages four through seven installed the front suspension and axle onto the chassis. There are lots of small fiddly parts here with uncertain locations so refer to the DVD pictures for placement of the parts. The axle assembly is installed to the chassis on page 6, and careful gluing of the nut, part #48 to the pin, #47 will allow the axle to rotate slightly. This will help getting all 6 wheels flat on the ground. The linkage part #120 on page seven broke off the pour block so I substituted one of styrene. Also the steering linkage #142 was too short so I extended it with a piece of brass rod. This linkage continued to break as I handled the Grader during assembly, and could be left off until all the wheels are installed.

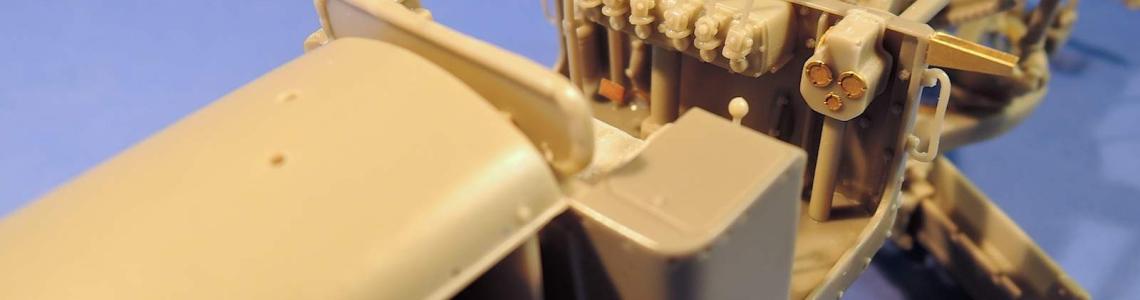

Pages seven through eleven add considerably more detail to the engine. Photoetch pieces #M5 and #M6 are used for the fan belt. Twelve very small pieces for the fuel system are installed to the left side of the engine on page eight. The photos on the DVD again are very helpful in correctly locating all of the parts. Using slow-setting superglue allows time to get the parts positioned correctly. There are lots of opportunities to add additional wiring and piping detail to the engine if desired. The exhaust manifold, part #133 is installed in step 9. I had trouble aligning the exhaust pipe with the manifold in step 23. It might be better to hold off attaching the manifold until the hood and exhaust pipe are installed to align them correctly.

Page 10 installs photoetch controls #M19, 20, 21, and 22 to the right side of the engine. These are parts that will break off several times while handling the engine during assembly. Page 11 installs a photoetch piece for the fan belt and the fan blade. The tank #111 didn’t seem to fit under the hood and behind the fan so I needed to re-do the riser on #112. Also check the fit of the intake pipe through the hood before gluing the tank in place.

Page 11 starts work on the Grader cab. On step 11, a plate, part #140, is attached to the underside of the cab without an exact location. The notch in the plate clears the rear of the transmission on the engine. Test fit the chassis at this point to check for clearance with the transmission. I had to notch out the underside of the cab to fit the transmission.

Step 12 installs the seat, controls, and instruments in the cab. The sides of the seat, parts #24 and #23 are miss-numbered and should both be #33. Also the lever #36 should be #31. The levers parts #15 and #30 are both incredibly thin. Hopefully they won't break off before the model is complete. Be careful removing the lever part #30 from the casting block as it includes a flange on the bottom of the lever. All of these parts for the interior are finally cast and have nice detail for the interior of the cab.

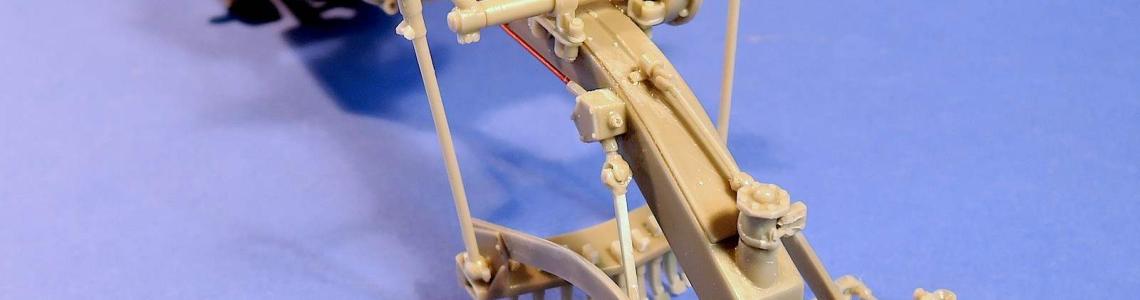

The bottom of page 13 resumes assembly of the working mechanism of the Grader. Page 15 shows assembly of a ripper assembly with parts #65, 66 and 67. This assembly may or may not have been installed on all US graders. Installation of the tilt mechanism for the blade starts on page 16 with part #72, and continues on page 17 with installation of parts #57 to the cab. This step also shows installation of the U-joint part #119 on the cab side for the control levers. The instructions show installation of the cab on the bottom of page 17. I chose to install the cab to the chassis first and then part #57 and #72 for the tilt mechanism to get everything spaced correctly. The instructions show to install the cab in front of the ridges on the chassis, but the DVD assembly photos show the cab behind the ridges. I installed the cab in front of the ridges and hoped for the best (everything fit later so this must be ok).

On page 18 the instructions show installation of the forward U-joints for the control levers parts #117 and then installation of the control arms on page 19. Note the angle of a part #143 and 115 on the U joint part #117.

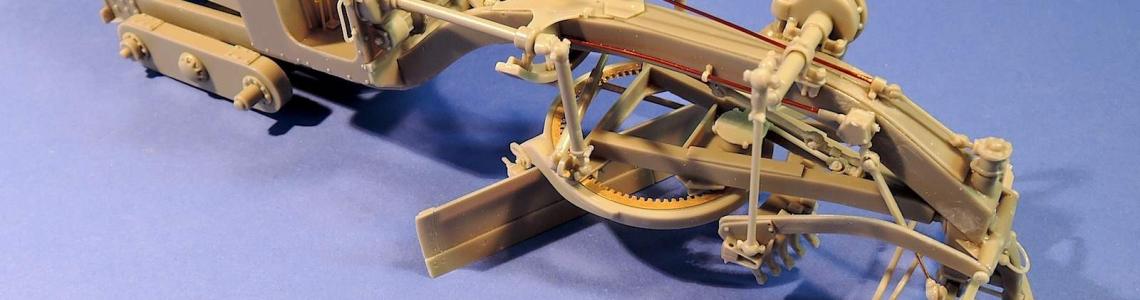

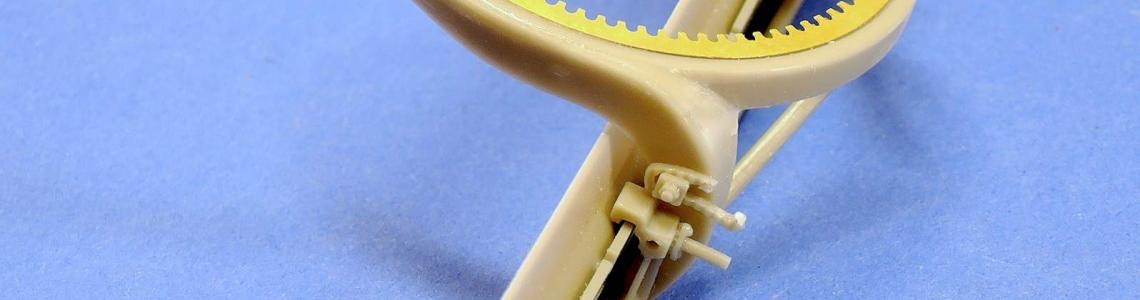

Page 20 begins installation of the heart of the Grader, the scraper blade. The ring gears, part #M1 and #M2 need to align and fit tightly together. The smaller ring #M2 fits inside the circle of part #17. I installed M1 first, which was easier to center and provided a surface for mounting part #M2. The small gears, part #43, are very delicate and I broke one trying to remove some flash. This step also installs the Grader blade, but I left it loose as it stays in place well without gluing.

Page 21 attaches the scraper blade’s rotating ring, part #17, to the lower frame, part #37. The rotating gear, part 130, has a hole for location, but is attached to the casting block without a mounting pin. I drilled through the attachment to the casting block and used a piece of styrene rod to create a mounting pin. This will be nipped off and the upper surface re-drilled after the glue dries. This step also installed several guides, parts #132 and #138 for the rotating ring. Parts #138 are both numbered #138 but are actually different, as can be seen by the hole locations on the DVD photos. The location pins for the guides, part #132, didn't seem to be in the right location for centering the ring. I centered the ring on the lower frame and glued them into place, hoping for the best.

Page 22 installs some of the linkage for the ring gear actuator, part #80. I left off the U-joint, part #117, until later to get the correct alignment. This page also shows installation of the radiator engine side panels, and rear bulkhead. The DVD photos show assembling all four parts prior to placing them on the grader, which worked pretty well. Page 23 shows installation of the hood over the engine and many of the vent pipes. I used the hood to check alignment of the radiator and rear bulkhead, but did not glue it on at this time pending painting of the engine. This would be a good time to install the exhaust manifold and exhaust pipe through the hood.

They top of page 24 finally installs the lower frame and scraper blade to the chassis. This assembly step required more hands and fingers then I had available. I used five-minute epoxy for the pin at the front of the frame and tried to center the frame on the chassis before installing parts #58 and #59 on each side. All of the wheels need to be on at this time to check the height of the blade. I wanted the blade flat on the ground in working position, so I placed it that way while gluing #58 & 59.

Step 25 installs the photoetch steps on each side of the greater cab. I soldered these together for additional strength and left them off for the time being to avoid breaking them off.

And with that I’m finally on to the last step, number 26. This step installs the very delicate control levers part #35, the steering wheel and column, the exterior lights, and grab bars on the side of the cab. There's lots of nice detail here particularly with the slender control levers.

A small detail sheet is provided with the vehicle number, serial number, Army star, and a four-leaf clover unit emblem.

The model was primed with Alclad’s gray primer and undercoated with AK Interactive old rust. AK Interactive Worn Effects was used underneath Life Colors UA223 olive drab and some minor chipping and wear was done by wetting the finish paint. I wanted this to be a working grader in good condition so chipping and wear was kept to a minimum. Painting was followed by SIN Industries brown filter for dark green, MIG Productions dark wash and oil and grease stain mixture on the working mechanisms. The scraper blade on working graders that I have seen are polished steel. To capture this look I used Alclad’s Chrome for a bright polished finish.

Summary

This is a great kit with wonderful detail, particularly in the complex working mechanism of the Grader. The kit goes together very well, but requires lots of skill in fitting and locating parts. This will be a enjoyable, challenging build for advanced modelers and will test all of their modeling skills. This kit should only be attempted by modelers with significant experience working with resin models. The finished kit is a handsome model of a very interesting vehicle.

Congratulations to Plus Model for producing a wonderful model of a unique World War II era piece of equipment. I really enjoyed the challenge of building this kit. Thanks to IPMS for the opportunity to review this great kit!

Comments

grader

Hi, the model has the option to towing mode, with the blade suspended?

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews