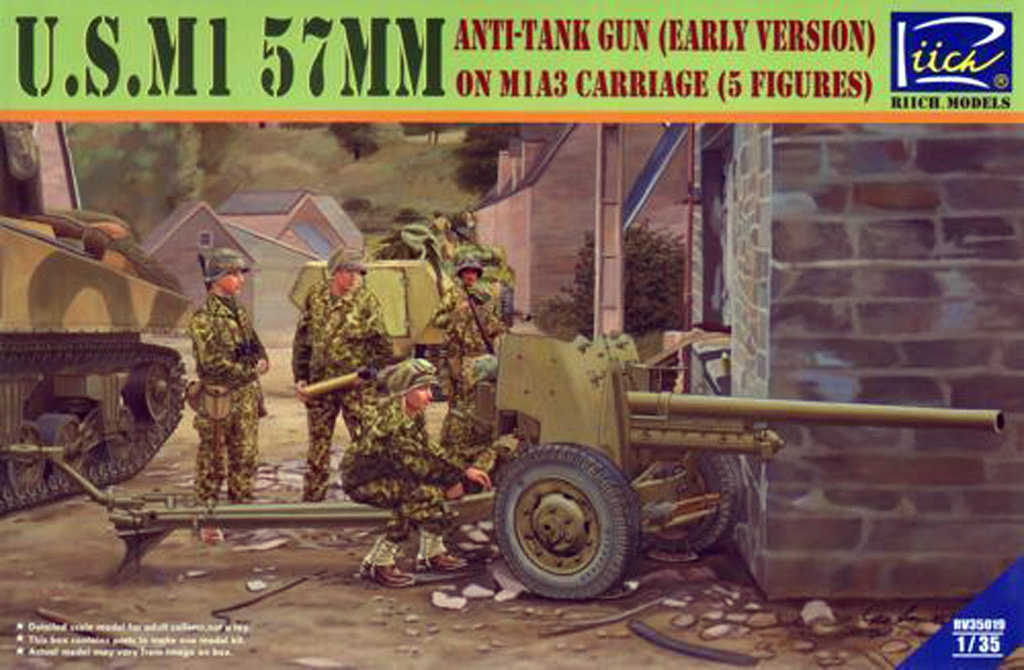

U.S. M1 57mm Anti-Tank Gun

History

The British 6 Pounder Anti-Tank gun was manufactured in the US, in 1942. In early 1943, the US Army adopted it for their use and called it the 57mm Anti-Tank gun M1. The version adopted for the army was modified and supplied to the army with a modified towing hitch and “Combat” wheels. Most branches of the US Army considered the weapon as too heavy and it was also hampered by the lack of ammunition. In 1943 only simple armor piercing ammo was manufactured. It wasn’t until late 1944 before adequate AP ammunition was made available. The M1 could penetrate 75mm of armor angled at 30 degrees at a distance of 3000 meters. In spite of the shortcomings, by early 1944 the M1 had become the standard towed anti-tank gun of the US Army Divisions. The prime mover for the M1 57mm was the Dodge WC-63 and the White halftrack. Over 10,000 M1’s were built for the US Army and 4,242 for the British Army. The M1 was also used by the Free French and Russian armies. Production of the M1 was ceased in 1945 and finally phased out of use by 1950.

The Build

Construction starts with the gun barrel. The breech end of the barrel is in two parts with a join seam running down the middle of the top and bottom halves. To this is added the muzzle half of the barrel which is a slide molded piece with an open muzzle. Added to the barrel is the slide (B16 & B30). Here is where the instructions start to get a little confusing. They have a No Glue symbol with lines running to each half of the slide. I think the lines are telling you not to use any glue on the top of the slide. The slide will have to be glued along the bottom seam. The slide halves fit over the rod on the bottom of the barrel assembly. Without gluing the barrel to the slide it will allow the barrel to move forwards and backwards along the slide. And we all know how important it is to be able to move the barrel while playing with the finished model. Once the gun and slide are joined you need to build the elevating yolk (Sorry but I don’t know what else to call it). It is necessary to glue two small parts (B49 & B50) to the right half of the yolk (B34). Look closely at the B parts tree. Parts B49 & 50 are so small you will need magnifiers just to see where to cut the part from the tree. Then you need to clean them up and glue to part B34 without launching them into oblivion. Also the instructions are not to clear on how they glue to B34. There are notches on the seam end of B34. The small parts have notches, which then fit into the notches on B34. Make sure the parts are lined up properly. Once these parts are on B34, they form an area where the left half B43 fits. It is absolutely necessary to make sure these parts are square to each other during assembly. Otherwise it poses a problem when adding the gun shield later in construction. I had a hard time getting this portion of the assembly correct. I squeezed too hard when joining the two halves and glue oozed out filling the bottom with plastic. At the time I was not aware that the area that filled with the oozed glue is where the barrel assembly is joined to the gun carriage. Just be take your time during assembly and make sure the part is square when done.

Next comes the breech block. As is typical, the breech block is two halves with the moveable breech door. The breech door handle is poseable so if the gun is displayed with the breech open the handle can be positioned correctly. There are a total of nine parts used in construction of the breech block. Once complete it was added to the barrel assembly with no fit issues. Moving on to the gun sight mount it will be necessary to clean the magnifiers as this assembly has many small parts. Starting with the base A28 add B14. PE part P4 fits over B14, gluing to A28, forming a bracket. Now complete assembly of the sight base with adding the other small parts. Once that done add the cover and the shoulder brace A11 & A31. There is a pin on part A11 to mount the padded shoulder brace (A31) but no corresponding hole on A31. Shave the pin off and glue the padded brace directly to the mount.

Now you get to deal with the actual gun sight. This consists of 11 small plastic parts and two very small PE parts. B22 is the sight adjustment knob. This glues to part B24, to which, is added PE part P13. Problem is B22, B24 and P13 are so tiny it was difficult for my gorilla fingers to fit the parts together. Let alone find where the PE part glues to the plastic part. The unclear instructions weren’t any help either. All I can say is dry fit, dry fit and dry fit again until you are sure how the parts fit together. Now that the sight is finished it is added to the base assembly (A28) which was placed on the gun earlier in this assembly step.

The gun shield is started next. On the front of the shield it is necessary to glue on four brackets that will hold a length of rope. The mounting locations were vague, so I deepened them slightly with a small drill bit to give a more positive gluing surface. On the rear of the shield are added three PE brackets, which once folded are glued at the indicated areas. Now two PE parts are folded to form a latch and then glued to the top of the tool box, which is then added to the area indicated on the top right side of the shield. When the shield is competed it is added to the gun assembly. Now you see how good you assembled the gun yoke (B34 & B43) in step one. If the assembly was square then the shield should fit with no issue. Dry fit the shield to the gun assembly to see the mounting points. The gun sight cover is now added to the front of the gun shield. It can be posed in the open or closed position. Parts are supplied that will allow you to pose it as needed. I chose to build my gun in the travelling mode as it is going to be behind a WC63. So I used the parts for the closed sight door. These parts went on with no issue.

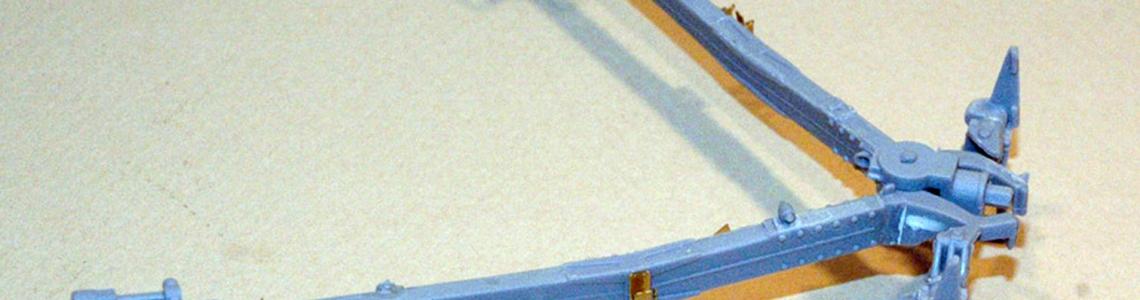

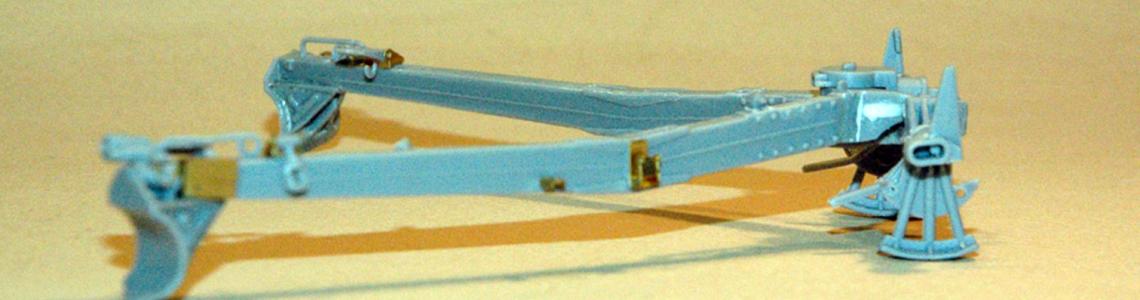

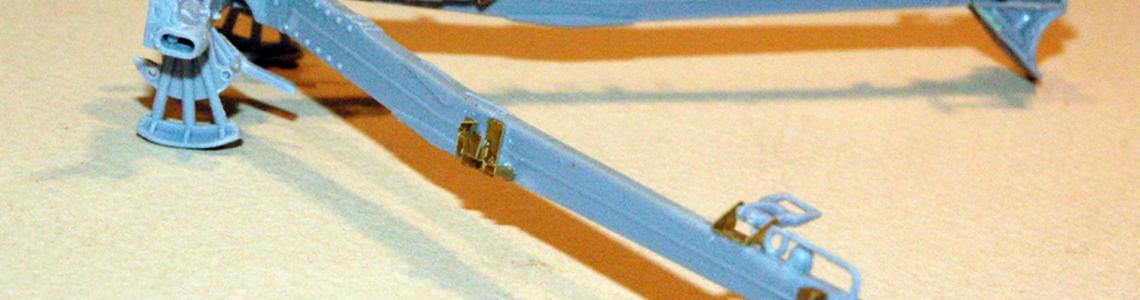

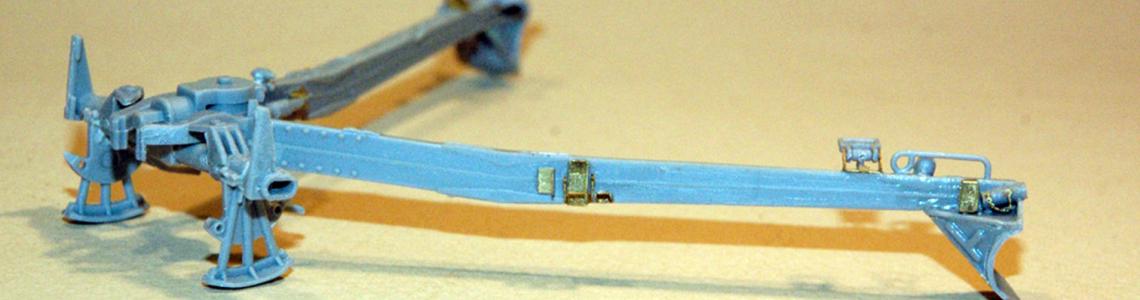

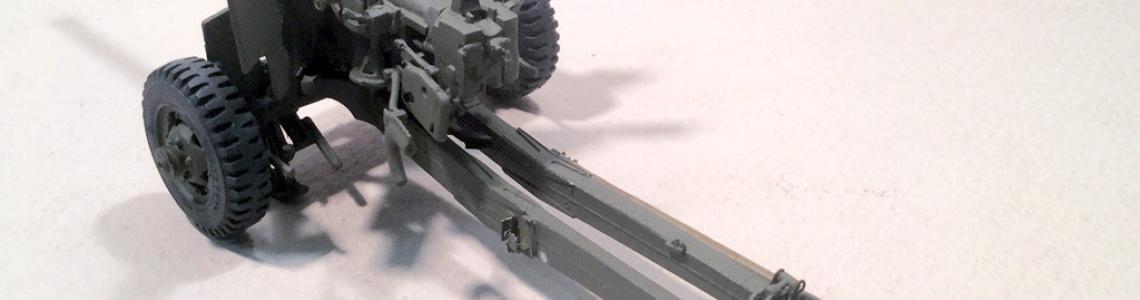

The trails are next. The construction of the trails have more parts than any other step in the building process. The right trail consists of 15 plastic parts and 7 PE parts and the left trail has 13 plastic and 7 PE parts. I would start by gluing the sides of each trail (A46 & B55, right and A4 & B8) together then the respective traverse mounts B5 & B6 to the trails. Now skip ahead to step 8 and build the axle mount parts A21 and A36. Now test fit the trails to the axle. Some filing or sanding may be needed to get the correct fit. Once the parts fit, go back to step 6 & 7 and complete the trails. It’s much easier test fitting the trails without all the fragile PE parts attached. Speaking of PE parts, each of the PE parts added to the trails will need to be bent to shape. The instructions are really poor in this area just showing the finished piece and not how to get it there. Some are really simple 90 degree bends, but the brackets for fitting the cleaning and sighting rods require intricate bends with no clear directions. I bent the first one incorrectly and then broke it as I was trying to re-bend it in the correct direction. I was able to repair the damaged bracket but clearer fold instructions would have been helpful. There were large knock out pins on the back of the recoil spade (part A24 & A25). This shouldn’t be an issue as they will be covered by the side and top plates. Various small parts are glued to the top of the trails and their positions are marked, however when I had completed my trails, I tried test fitting and closing the trails in the travelling position, and found that the cup A15 on the top of the left trail did not line up with the ball A44 on the top of the right trail. I had to cut A15 off and reposition it correctly.

Now go back and complete the construction of the axle in step 8. The trails are fitted and a square headed pin is inserted to lock the trails to the axle. The square head sticks out the top of the axle mount and this square head is what fits into the bottom of the gun mount. If you are really careful you can glue the mount to the axle so it will traverse. However, reality hits here and that is when I discovered the oozed glue from step 1 closed up the mounting area. I had to drill out the blockage to get the gun mounted to the axle.

The US gun calls for the combat tires. These are nicely molded and detail is crisp. Even has a nice rendering of the Firestone name and tire size. The tire drum consists of 4 parts which includes the brake handle. After construction of the tire drum it is added to the wheel and held in place by passing a pin part E13 through the drum and then the wheel, locking it in place with a small ring, part B51. Then a small cover Part B51 is added and a small tie down ring added to the cover. The wheels are then added to the axle mount, being sure the brake handles face rearward.

The front shield is next. It consists of a vertical upper shield and a folding lower shield. Pioneer tools are strapped to the lower shield and the head of the pick axe is strapped to the upper shield. I differed from the instructions in not adding the tools. I painted them separately then added them at the end of the construction. I had a hard time getting part B35 in position. Once in place it fit okay but getting it into position took a few tries. On the actual gun the lower portion is folded upwards 90 degrees and held in place with a wire hook that fits into a footman loop. These footman loops are etched brass and need to be folded into position. I found this really difficult and frustrating. After breaking two of them I decided to make loops from thin wire and glue them into position. Then I just had to thread the wire clasps PE part P25 into the loops and glue them in position with a drop of CA glue. Another frustrating thing is the straps for the pioneer tools are also etched brass. This was very stiff and they would have you fold over the tools and thread through a simulated buckle. If you can pull this off then you are a better man than I am Gunga Din. I tossed the etched straps and made new ones from lead foil and PE buckles. The kit comes with a length of thread to simulate the rope coiled on the front shield. Unfortunately, it is bleached white. I replaced the kit supplied thread for a similar sized tan thread that looks more like real rope. After adding the reciprocator cover (B31 & B32) the front shield can be glued to the gun.

After adding the front shield I painted the finished gun with Tamiya Olive Drab mixed 2 to 1 with Tamiya dark yellow. Wheels are painted Vallejo black grey. After adding the poles to the sides of the trails the gun is done.

Conclusion

The Riich Models 57mm M1 builds into a very nice rendition of the actual gun. It is nicely detailed with crisp moldings. However, to get to a finished model it will take some work. This is not a shake and bake kit. It will take some experience with tiny parts and PE that requires multiple folds. The complexity of the parts is hindered by unclear instructions. Some of folds for the PE parts are self-explanatory however there are a few parts that require multiple folds and these folds are not shown in the instruction sheet. I had to re-bend one piece and ended up breaking it, requiring a repair job. Another issue was the small parts (read tiny). If they can mold something that small then they should not have a problem molding small footman loops for the equipment etc. At least as molded plastic they would better represent the actual loop than a flat piece. Given the issues with my build I can only recommend this kit to a modeler with experience dealing with PE and very small parts. That being said I am happy with the final results of this review build and would attempt another. Thanks to Dragon Models USA and Riich Models for the opportunity to build and review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews